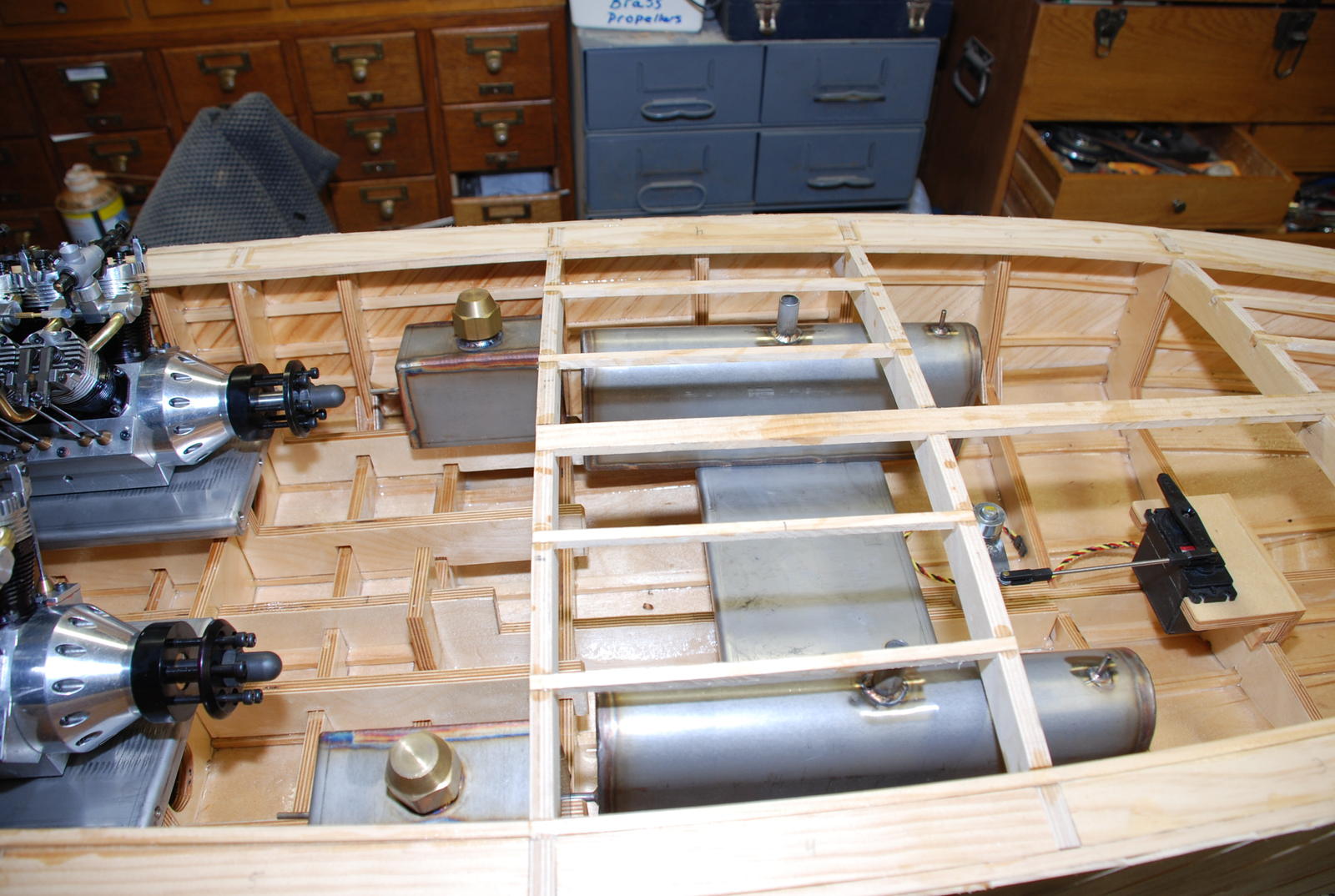

1:3 scale garwood speedster wooden boat build!

whitefish replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

Ditto on Ian Webster's comments about rudders.

Also, size does matter but mostly it affects the steering quality. It does

not have a large impact on the forward motion of the boat. It is much like

a sharp knife passing thru water. Extra length is the only aspect that adds

resistance and it does not add much when a rudder is properly sharpened. You

can run traditional wide blade rudders or narrow profile speed rudders. Use

whatever makes the boat handle the way you expect it to.

The scale floor boards with water lines underneath sounds like a neat

trick!

You have the right idea on cooling a submerged prop R/C boat. Throw at it

everything you can think of for initial trial runs. It is easier to take

some cooling away then to add more in after the fact. I only wish I had been

clever enough to know that on my first submerged prop R/C.

More thinking out loud. Have you heard about or experienced Smith's Clear

Penetrating Epoxy Sealer? As nice a woodie as you are constructing this

product is something to look into. All of the claims about the product are

true. It is just as beneficial to new construction as it is to restoration

projects. There is no other product in the wood conditioning/preservation

industry that comes close to it's formula (unless someone has hacked it

and I am not aware). The Rot Doctor still probably sells more Smith's CPES

than anyone.

www.rotdoctor.com/products/product.html

Also, size does matter but mostly it affects the steering quality. It does

not have a large impact on the forward motion of the boat. It is much like

a sharp knife passing thru water. Extra length is the only aspect that adds

resistance and it does not add much when a rudder is properly sharpened. You

can run traditional wide blade rudders or narrow profile speed rudders. Use

whatever makes the boat handle the way you expect it to.

The scale floor boards with water lines underneath sounds like a neat

trick!

You have the right idea on cooling a submerged prop R/C boat. Throw at it

everything you can think of for initial trial runs. It is easier to take

some cooling away then to add more in after the fact. I only wish I had been

clever enough to know that on my first submerged prop R/C.

More thinking out loud. Have you heard about or experienced Smith's Clear

Penetrating Epoxy Sealer? As nice a woodie as you are constructing this

product is something to look into. All of the claims about the product are

true. It is just as beneficial to new construction as it is to restoration

projects. There is no other product in the wood conditioning/preservation

industry that comes close to it's formula (unless someone has hacked it

and I am not aware). The Rot Doctor still probably sells more Smith's CPES

than anyone.

www.rotdoctor.com/products/product.html

The following user(s) said Thank You: smokeater2005

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

smokeater2005 replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

Wow the more i crank out numbers, fittings, cables, and props the more i begin to think that a scale drive on this size wood boat would be cool in theory but crappy at best in practice. What i mean is that I do want it to reach more than 20mph and have a decent turning ability...

The size prop i would want only comes for 3/16 drive shafts and thats way to small for a 14hp rcmk k600.. it would even snap dual 3/16 drives of this size i bet...

I believe I am going to have to use a standard rear mounted strut/rudder or stinger/rudder combo! of which i would rather do a stinger/rudder combo but because of the keel and construction i may have to use a strut/rudder so that the prop height will be correct. I believe that this would also allow me to run a larger 2 or 3 blade prop in surface mode once the boat gets on plane...

the only other idea i had was twin jet drives, a single jet drive would not be allowed as because of the boat design and construction. but the dual jet drive would be alright i guess...?...

any comments or ideas?

The size prop i would want only comes for 3/16 drive shafts and thats way to small for a 14hp rcmk k600.. it would even snap dual 3/16 drives of this size i bet...

I believe I am going to have to use a standard rear mounted strut/rudder or stinger/rudder combo! of which i would rather do a stinger/rudder combo but because of the keel and construction i may have to use a strut/rudder so that the prop height will be correct. I believe that this would also allow me to run a larger 2 or 3 blade prop in surface mode once the boat gets on plane...

the only other idea i had was twin jet drives, a single jet drive would not be allowed as because of the boat design and construction. but the dual jet drive would be alright i guess...?...

any comments or ideas?

Please Log in or Create an account to join the conversation.

- smokeater2005

- Offline

- Posts: 172

- Karma: 3

- Thank you received: 5

smokeater2005 replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

z drive

maybe this would be a good fit...

maybe this would be a good fit...

Last edit: 13 years 5 months ago by smokeater2005.

Please Log in or Create an account to join the conversation.

- smokeater2005

- Offline

- Posts: 172

- Karma: 3

- Thank you received: 5

whitefish replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

For now, I would abandon the twin cylinder engines idea. The main reason

is lack of choices on headers available which makes configuring the entire

exhaust system a lot more difficult. Also, the motor is limited to the extra

large flex shafts. Scott (Admin on this Forum) can tell you all about these

types - most or all of this gear is European.

All you need is a pair of 27+ cc high performance engines spinning the

Octura 2.4/3 prop (Dia. 60.9mm with 1/4 in. bore). The CY F273 would work or

an RMCK side exhaust is a good choice too. I prefer the F273 because it is

a +2mm factory stroker. Has a lot of low RPM grunt. You will have an

impressive hole shot (the 65in. hull will literally leap on top of the

water) and top speed is probably going to be something well above 35mph.

The top scale speed of the boat will be far in excess of what the original

FS boats could do. Note: If the engines will not spin at high RPM than the

diameter of the props may need to be reduced slightly. I reduce mine to

58mm (for single engine, 22 lbs. Deep-V C-Box hull) and something near this

size may be required.

Some of the Octura Prop Charts I have seen on-line list this prop as having a

3/16" bore - cannot explain that. I get 'em with the 1/4" bore from Fun R/C

Boats.

A counter rotator is nice but not essential. With some generous cavitation

plates, you won't have any problem eliminating the torque roll and having

her zip across the pond on the level. Remember that finding a Right hand prop

similar to the rather unusual Octura 2.4/3 is not easy to do. If you ever

do find one, please let me know.

I would start with a pair of lefties. Only after I could not adjust that

to satisfaction would I insist on a right hand engine and prop - those can

be such a PITA just because of the limited props available.

__________________________________________________________________

Correction posted 08-23-12

While making a new flex shaft (again) and rechecking the balance on an Octura

2.4/3, I just remembered that I posted an incorrect size for the diameter used

on my submerged prop V-Box. It should have been 48mm instead of 58mm. My bad.

is lack of choices on headers available which makes configuring the entire

exhaust system a lot more difficult. Also, the motor is limited to the extra

large flex shafts. Scott (Admin on this Forum) can tell you all about these

types - most or all of this gear is European.

All you need is a pair of 27+ cc high performance engines spinning the

Octura 2.4/3 prop (Dia. 60.9mm with 1/4 in. bore). The CY F273 would work or

an RMCK side exhaust is a good choice too. I prefer the F273 because it is

a +2mm factory stroker. Has a lot of low RPM grunt. You will have an

impressive hole shot (the 65in. hull will literally leap on top of the

water) and top speed is probably going to be something well above 35mph.

The top scale speed of the boat will be far in excess of what the original

FS boats could do. Note: If the engines will not spin at high RPM than the

diameter of the props may need to be reduced slightly. I reduce mine to

58mm (for single engine, 22 lbs. Deep-V C-Box hull) and something near this

size may be required.

Some of the Octura Prop Charts I have seen on-line list this prop as having a

3/16" bore - cannot explain that. I get 'em with the 1/4" bore from Fun R/C

Boats.

A counter rotator is nice but not essential. With some generous cavitation

plates, you won't have any problem eliminating the torque roll and having

her zip across the pond on the level. Remember that finding a Right hand prop

similar to the rather unusual Octura 2.4/3 is not easy to do. If you ever

do find one, please let me know.

I would start with a pair of lefties. Only after I could not adjust that

to satisfaction would I insist on a right hand engine and prop - those can

be such a PITA just because of the limited props available.

__________________________________________________________________

Correction posted 08-23-12

While making a new flex shaft (again) and rechecking the balance on an Octura

2.4/3, I just remembered that I posted an incorrect size for the diameter used

on my submerged prop V-Box. It should have been 48mm instead of 58mm. My bad.

Last edit: 13 years 5 months ago by whitefish. Reason: correction

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

smokeater2005 replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

i believe i am going to have to agree with you that the twin rcmk is just not the best choise due to headers and other parts not being available for this type of build.

with a twin engine twin prop setup,

maybe these props

1457 57mm 2.24" 1.4 x 2.24 = 3.136 .187

1457R 57mm 2.24" 1.4 x 2.24 = 3.136 .187

i have found a 3/16" shaft 7.5 degree drop angle bottom mounted strut, but i dont know if a 3/16 shaft/flex cable would hold up to a rcmk 27.5cc motor? any thoughts?

Also what about entertaining an old school speed boat steering setup...se pic as the steering is up front near where a skeg would normaly be placed... nifty idea i thought

with a twin engine twin prop setup,

maybe these props

1457 57mm 2.24" 1.4 x 2.24 = 3.136 .187

1457R 57mm 2.24" 1.4 x 2.24 = 3.136 .187

i have found a 3/16" shaft 7.5 degree drop angle bottom mounted strut, but i dont know if a 3/16 shaft/flex cable would hold up to a rcmk 27.5cc motor? any thoughts?

Also what about entertaining an old school speed boat steering setup...se pic as the steering is up front near where a skeg would normaly be placed... nifty idea i thought

Please Log in or Create an account to join the conversation.

- smokeater2005

- Offline

- Posts: 172

- Karma: 3

- Thank you received: 5

smokeater2005 replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

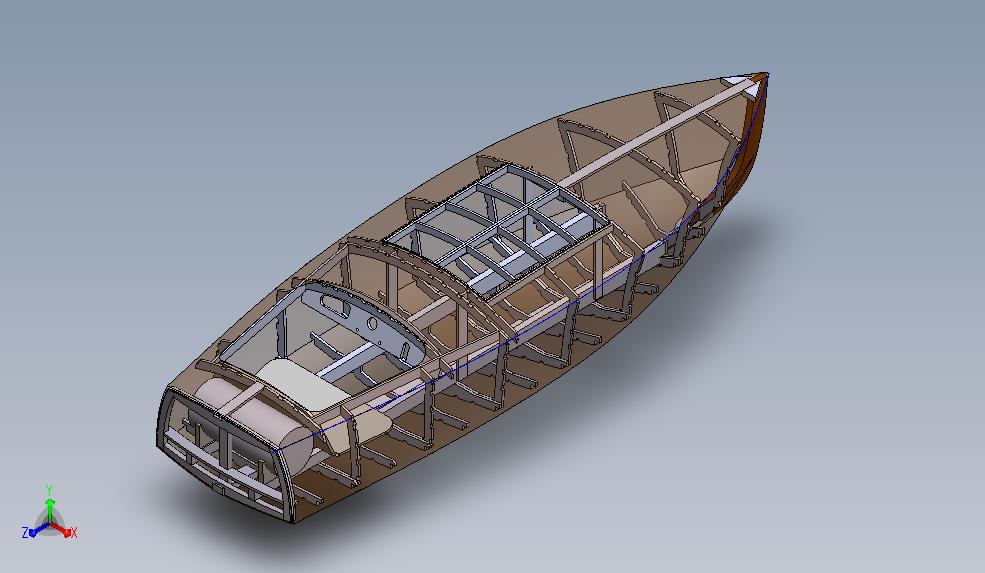

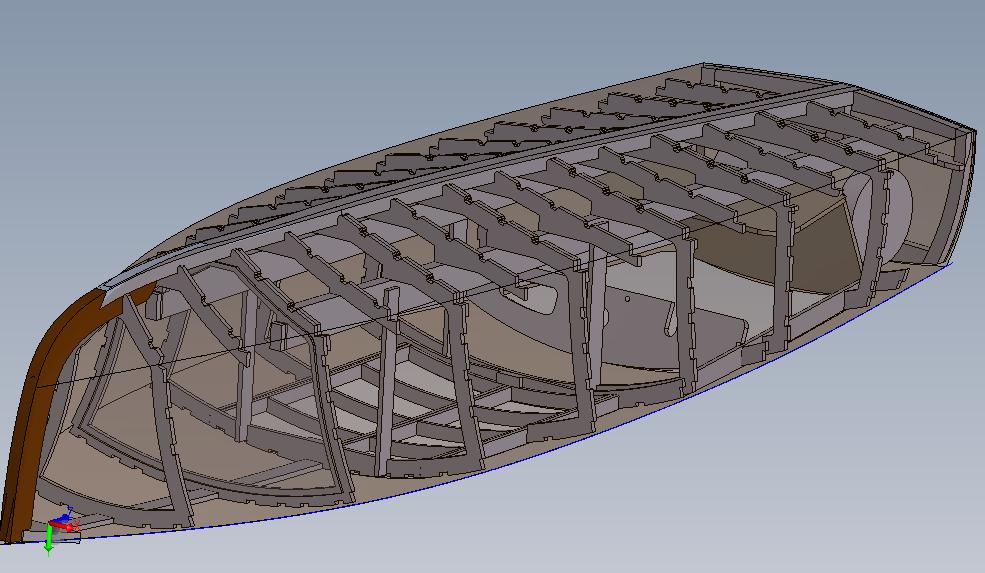

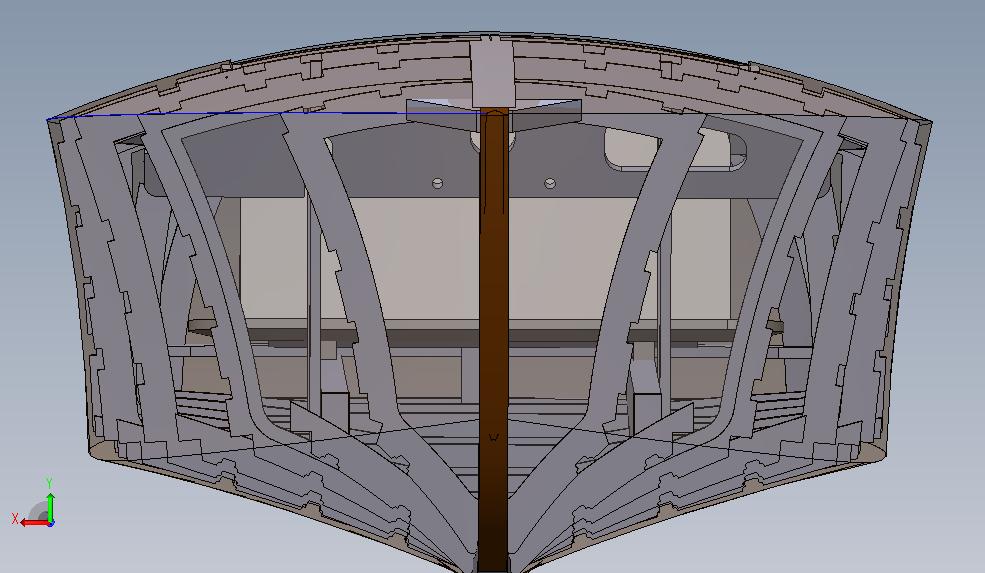

some 3d pics of the boat bones im cutting out!

Please Log in or Create an account to join the conversation.

- smokeater2005

- Offline

- Posts: 172

- Karma: 3

- Thank you received: 5

whitefish replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

smokeater 2005 wrote:

>i have found a 3/16" shaft 7.5 degree drop angle bottom mounted strut, but i dont

>know if a 3/16 shaft/flex cable would hold up to a rcmk 27.5cc motor? any thoughts?

AFAIK, the only 3/16" shaft that will hold up to 27-28cc is a solid. CY F273 will rip up lesser quality 1/4" flex shaft with ease. It can damage the better quality flex shafts too - it just takes longer. RCMK will probably do it just as easy.

If had it to do over again, I would have used a 1/4" solid SS shaft. I can make these myself and they would hold up better than any flex made. I would have had to make my own strut as well (which I was trying to avoid) but I would have spent a lot less time resizing and fitting flex shafts.

I'm thinking about rebuilding the hull in a 49-50 inch version. If I do, I will definitely run a solid shaft. I want the motor moved forward to decrease the shaft angle. Move the fuel load, pump and servos rearward to maintain the COG. Probably do one this winter.

Struts: The only 1/4" bore bottom mounted struts I know of are Marine Specialties.

These are tough struts that can take some abuse. Somebody else makes one but I cannot remember who - it may be something the NAVIGA boaters uses. Marine Specialties double skeg turn fin is nice hardware and also well made.

>i have found a 3/16" shaft 7.5 degree drop angle bottom mounted strut, but i dont

>know if a 3/16 shaft/flex cable would hold up to a rcmk 27.5cc motor? any thoughts?

AFAIK, the only 3/16" shaft that will hold up to 27-28cc is a solid. CY F273 will rip up lesser quality 1/4" flex shaft with ease. It can damage the better quality flex shafts too - it just takes longer. RCMK will probably do it just as easy.

If had it to do over again, I would have used a 1/4" solid SS shaft. I can make these myself and they would hold up better than any flex made. I would have had to make my own strut as well (which I was trying to avoid) but I would have spent a lot less time resizing and fitting flex shafts.

I'm thinking about rebuilding the hull in a 49-50 inch version. If I do, I will definitely run a solid shaft. I want the motor moved forward to decrease the shaft angle. Move the fuel load, pump and servos rearward to maintain the COG. Probably do one this winter.

Struts: The only 1/4" bore bottom mounted struts I know of are Marine Specialties.

These are tough struts that can take some abuse. Somebody else makes one but I cannot remember who - it may be something the NAVIGA boaters uses. Marine Specialties double skeg turn fin is nice hardware and also well made.

Last edit: 13 years 5 months ago by whitefish. Reason: punctuation

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

smokeater2005 replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

Ok, Yes seriously im back... I had to table all building until I was settled into a routine for this semester in BSN Nursing school...

Anyway, so on my few moments I have had to ponder my wood boat build, I have come up with a few understandings with myself.

1. a twin cylinder is not very practical in this setup

2. a twin drive is also not very practical due to how the wooden boat is built and how things need to attach to the boats bottom...

3. I think that a 27cc single cylinder engine will work fine as long as I dont get to crazy with multi layers of wood IE not a four layer scale build up, more like a 2 layer side and a 3 layer bottom with minimal up top for weight reduction.

4. A single prop with a high quality flex shaft and a rear-inline-threw hull mounted rudder "just like the real ones" would satisfy my outward scale "OCD" while getting me as close to 30 mph as I am most likly going to get...

I am going to focus on banging out some more frames in the next two weeks and finishing the jig. More pics to come...

Anyway, so on my few moments I have had to ponder my wood boat build, I have come up with a few understandings with myself.

1. a twin cylinder is not very practical in this setup

2. a twin drive is also not very practical due to how the wooden boat is built and how things need to attach to the boats bottom...

3. I think that a 27cc single cylinder engine will work fine as long as I dont get to crazy with multi layers of wood IE not a four layer scale build up, more like a 2 layer side and a 3 layer bottom with minimal up top for weight reduction.

4. A single prop with a high quality flex shaft and a rear-inline-threw hull mounted rudder "just like the real ones" would satisfy my outward scale "OCD" while getting me as close to 30 mph as I am most likly going to get...

I am going to focus on banging out some more frames in the next two weeks and finishing the jig. More pics to come...

Please Log in or Create an account to join the conversation.

- smokeater2005

- Offline

- Posts: 172

- Karma: 3

- Thank you received: 5

smokeater2005 replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

IM BACK... and coming soon!

frame pics... i have all the frames layed up ready to cut out and a few already cut out...

jig construction and finish pics... about 60% complete...

more questions about material thickness and layers... 1/32 vs. 1/64?

wouldnt 1/64 basicaly be transparent?

would 1/32" X2 layers (sides and bottom) be to heavy for a 29cc motor to plane out...

because im not in a hurry to finish, and like the realistic scale look of wood I have been looking at a scale supply company and there prefab wood (thickness X 1-4" wide X 24" long) for a two layer plank over frame/battens with a woven carbon fiber/kevlar layer sandwiched inbetween,

frame pics... i have all the frames layed up ready to cut out and a few already cut out...

jig construction and finish pics... about 60% complete...

more questions about material thickness and layers... 1/32 vs. 1/64?

wouldnt 1/64 basicaly be transparent?

would 1/32" X2 layers (sides and bottom) be to heavy for a 29cc motor to plane out...

because im not in a hurry to finish, and like the realistic scale look of wood I have been looking at a scale supply company and there prefab wood (thickness X 1-4" wide X 24" long) for a two layer plank over frame/battens with a woven carbon fiber/kevlar layer sandwiched inbetween,

Please Log in or Create an account to join the conversation.

- smokeater2005

- Offline

- Posts: 172

- Karma: 3

- Thank you received: 5

woody replied the topic: Re: 1:3 scale garwood speedster wooden boat build!

Hi Smoke and wellcome back. (Look to your karma).

Your'e just like me in getting "a bit late" but still getting on and off...

About your build, I'm not sure that you need that many inside stringers as shown in the drawings. It could be unnessecary trouble to get them aligned to the final hull shape. Anyway you should take care that the stringers are wide enough to stick outside the profiles, and then you can use a small scale plane and then maybe sand them down to get the right shape to support the skin.

As said I think you maybe can drop one or two of the inside stringers on each surface. You just have to use a "thick" and rough planking in the first layer when doing the planking. Then sand it smooth and put two thinner diagonal layers on it. Last layer should be "thick" too, but now done with extreme precision in cutting and glueing.

If you follow this method, you get a light wooden hull, about 4 mm thick and stronger that most "polyester miracles", that has few or no profiles inside, which means that you can save weight by grinding about 50 - 75 percen off the profiles inside edge - once the planking is done.

A cross planked hull will be extremely strong and stiff - even with few or no profiles inside.

The cross planking method takes time to do. But if the finish is done right and shows perfect outside wooden planking, the result will blow everybody's mind.

Just an advice about how I would do it.

Now let's get some pics!

Cheers!

Lars

Your'e just like me in getting "a bit late" but still getting on and off...

About your build, I'm not sure that you need that many inside stringers as shown in the drawings. It could be unnessecary trouble to get them aligned to the final hull shape. Anyway you should take care that the stringers are wide enough to stick outside the profiles, and then you can use a small scale plane and then maybe sand them down to get the right shape to support the skin.

As said I think you maybe can drop one or two of the inside stringers on each surface. You just have to use a "thick" and rough planking in the first layer when doing the planking. Then sand it smooth and put two thinner diagonal layers on it. Last layer should be "thick" too, but now done with extreme precision in cutting and glueing.

If you follow this method, you get a light wooden hull, about 4 mm thick and stronger that most "polyester miracles", that has few or no profiles inside, which means that you can save weight by grinding about 50 - 75 percen off the profiles inside edge - once the planking is done.

A cross planked hull will be extremely strong and stiff - even with few or no profiles inside.

The cross planking method takes time to do. But if the finish is done right and shows perfect outside wooden planking, the result will blow everybody's mind.

Just an advice about how I would do it.

Now let's get some pics!

Cheers!

Lars

Last edit: 12 years 11 months ago by woody.

Please Log in or Create an account to join the conversation.

- woody

- Offline

- Posts: 100

- Karma: 4

- Thank you received: 11

Time to create page: 0.090 seconds