Improving Your Prop

This information posted with permission from Carlos Andrade (Shark Racing)

Improving your propeller by Mike T.

Everybody knows that any and every propeller can be improved from it's stock form. It's not easy and requires special tools, but it can be done. Mike T. got the ticket to it and bellow he gracious teach us how to do it. All the tools showed where made by him and indeed look very professional.

|

Step - |

Tools & Supplies - |

Comments - |

|

1. Plan the job. Look prop over, decide what your objective is. |

Personal computer Jims RC Boat Dock Message Board |

Ask questions. Dont try to reinvent the wheel. Remember, a prop gets smaller every time you resharpen it, leave some material for later. |

|

2. Gather everything you need to do the job. |

Prop holder Prop mold Pitch gauge Prop balancer Outside calipers Non-marring hammer Wood block to hammer on Bench vise Flat file Round file (chainsaw file) Flat sticks (tongue depressor) Marker pen Card stock or brass sheet Emery cloth or sandpaper Dremel with cratex wheel Dremel felt polishing bobs Dremel polishing compound |

Plus mandatory safety gear Dont skimp here - Goggles, dust mask, rubber gloves and leather gloves, long sleeve shirt, long pants, socks and shoes. Metal dust, especially Beryllium dust, is dangerous to breathe and bad for your skin & eyes. Head for the shower when you get done. Wash those clothes separately. Vacuum the dust from workbench and floor. |

|

3. File off molding flash. |

Prop holder Flat file Round file |

|

|

4. Check balance and alignment. |

Prop balancer Marker pen |

Mark the heavy blade. Look for misaligned blades. |

|

5. Grind and sand face and hub to remove sand cast texture and flaws. |

Prop holder Flat file Round file Emery cloth or sandpaper Flat stick Dremel with Cratex wheel |

Do this now so any rounding of the edge of the face will be removed in later steps. Use emery cloth folded over end of stick to reach into the concave areas. Dont remove the concave shape. See warnings in #13 when using the Dremel or any other power tool on a prop. |

|

6. Mark new blade profile on face |

Template from card stock or brass sheet. |

Lift shape from another prop that works well. Use template to get both blades the same size and shape. |

|

7. Thin from back side, file flash and imperfections from blade joint. Check balance. |

Prop holder Flat file Round file Emery cloth Calipers Prop balancer |

Check thickness before you start. Try not to over do this step. There is usually lots of material near the center. Is the same blade heavy as in step #4? Dont work too hard to balance yet, but extra thinning of the heavy blade might be in order. |

|

8. Cut blade profile, leave a little extra to trim later.Check balance. |

Prop holder Flat file Prop balancer |

If balance is now way off, make sure the blades both have the same profile. Is the same blade heavy as in step #4 and #7? Mark the heavy blade. |

|

9. Adjust pitch and cup. |

Prop holder Pitch gauge Prop mold Pliers & shim stock Non-marring hammer Wood block to hammer on |

Could write a book here. Work carefully. If you dont mar or dent the blades with tools you wont have so much to clean up later. |

|

10. File and sand more material off the back to balance. |

Prop holder Flat file Emery cloth and stick Prop balancer |

It takes a lot of filing to change balance much. Check balance as you go. |

|

11. Sand all over, final sharpen, file trailing edge to sharpen. |

Prop holder Emery cloth and stick Flat file |

Sharpen with face up, using file then emery cloth on stick.Be careful not to roll edge. Wear leather gloves or cut your fingers. |

|

12. Check balance again. Sand or file to correct. |

Prop balancer |

Go back to #10 if balance is off. |

|

13. Polish if desired. |

Prop holder Dremel with felt bob Dremel polishing compound Some safer ways to get a little less shine: wet sand with soap and #600 paper under running water, polish with Brillo, polish with a paste metal polish like Simicrome. |

Wear a dust mask. Be careful near edges, always run wheel or bob rotation away from edge so it cant grab, wear leather gloves and goggles. Dont stand in line with dust being thrown off the work. If you are not confident using a power tool on props, please dont do it. |

Now, the pics of the tools he hand made for the job.

Prop mold

Prop mold, plus holder

The complete array of tools

Pliers he modified to cup and pitch props

What Mike says about it:

They

have a rounded "drum" shape that is good for the side and trailing edges and

some cup in the end. You could make it more round to do the ends better. These

were OXO brand kitchen pliers I found on sale. They ground down real easily with

the sanding belt (probably not real hard metal) and polished up on the buffer to

make a smooth finish. I can grab a part of the edge of the blade with the pliers

at an outward angle and just squeeze real hard to put the cup in. Not the same

as squeezing then pulling out.

I'll send Carlos some more pics

soon.

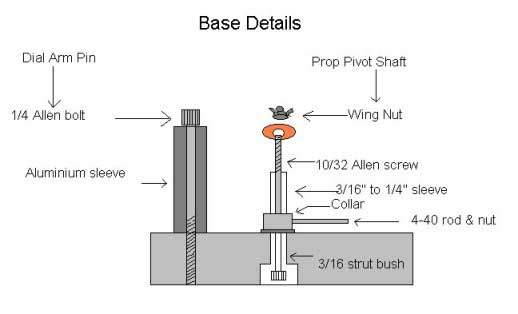

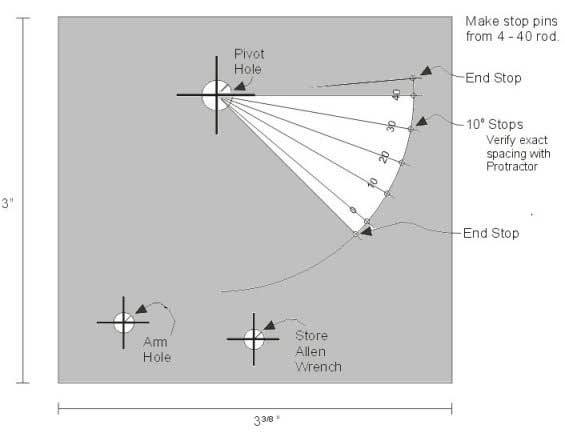

How To Diagrams (from originals hand-made by Mike T.)

This is a question posted by Dave (MobilDave) and answered by Mike. I suppose it can be useful for anyone intending to make the tools, so I posted the Q and A here:

Q: "What

is the measurement from the bolt that holds the prop to the degree stop

holes?

Are the degree stop holes drilled exactly on the centerline for each

stop rod to the center of the prop bolt or should the face of the rod be the

centerline?

Thanks in advance Dave D."

A: "Ah. yes, the finer details... The distance out from the prop pivot shaft isn't so critical, except the farther out is better because then drilling errors don't cause as much measurement error. I just center punched for the prop pivot hole, then took a divider and swung an arc out near the edge of the plate. Then I took a small protractor and marked 10-degree intervals going 0-10-20-30-40 (5 holes) along the arc. Now if you center and drill each pin stop hole directly on a 10-degree mark, you're in good shape. You need two more holes, the end stops. (If you just put the handle between pins in the 0 and the 10 and pivoted between them, it would only travel 10 minus the width of the handle and one pin.) If you put a pin in the 0 hole, and the pivot handle on the outside of the pin, then mark and drill the end stop hard up against the outside of that. That way from the inside of the end stop to a pin in the 10 degree hole will be 10 degrees. To the next pin is 20 degrees, etc. Make the pins from pieces cut from a 4-40 rod. Use a drill press and a centering bit to place and drill the holes accurately, don't drill all the way through the plate so the pins don't fall out the bottom. See Harbor Freight for the dial indicator and the centering drill bits. I will e-mail the pictures. Have fun."

And a few more questions addressed at the board that makes easier understanding how things work. Mike T. got permission to me to post them.

Some Dialogue from Jims Board and e-mails Related to Using a Prop Gauge.

Some Dialogue from Jims Board and e-mails Related to Using a Prop Gauge.

Mike Kolder: I got the tables (Thanks Mike T!) for doing so. How many places on the prop do you measure & for how many degrees? To measure the last cup do you only measure the last 5 degrees? Mike, that prop of yours ended up at 5.28 pitch for the last 15 degrees. Does that sound right? How do you measure the whole blade at once to compare to the other one? If you start on the outside of the tongue, by the time your at the end of the prop your in the bar cut area.

Mike T: Now you're finding what I did - that when you have an Andy Brown prop with a stated 6.0 of pitch, you can't seem to get that reading anywhere but the final 5 degrees of the cup. The only other way I find 6-something of pitch there is to pivot the arm outward as I turn the prop over 20 degrees, letting the dial gauge follow the trough of the blade (which is how the water travels over the blade anyway). Yes, to measure the cup, just use 5 degrees and set the gauge so it climbs the cup. Remember the end of the dial gauge probe is a ball, so don't use up degrees of motion just climbing from the side of the ball to the tip of the ball, that's "measuring the ball" and not the prop. The pitch gauge is useful as a means of comparison (one blade to the other, one prop to another) and a means of exploring the shape of different parts of a prop as much as it is for determining the actual pitch number of a prop. To find the "total" pitch of a prop, you just need to measure the total degrees one blade spans and the total inches one blade displaces, and do the math. Example: if one blade is 90 degrees (1/4 circle) and rises one inch, the total pitch is 4 inches. The total pitch is usually less than you would measure higher up on the blade (progressive pitch).

Mike

Kolder: Im going to try to tweak more pitch into that 1475 you gave me. Do you

have a picture of the prop pliers you made? Wish I still had those AB props to

measure now but Riph is the new owner.

Mike T: When I did that one I used

ordinary pliers and strips of brass bent around the blade so the pliers wouldn't

scratch the blade. I used Channel-Locks to reach the center of the blade from

the trailing end and slip-joint mechanic's pliers to restore the cup on the

edge. Any time you reach way down and pull up the end of the blade, a part of

the edge cup will fall out - usually about 1/3 of the way down along the side.

Thats the nature of a compound bend. The other day I was in the kitchen store

(gasp) with my wife and found a nice pair of pliers on sale, with big rubber

grips and satin chrome finish for $6. They were originally $16. I bought them

and took them out to the shop and made cupping pliers - One side smoothed but

basically flat, the other makes a sort of dowel shaped part. I'll send you a

picture.

Mike Kolder: Do you prefer the pliers or tapping over the rounded wood with a plastic hammer? Ive got some CRAZY ideas for props. Why must a prop continue to turn deeper after the tongue enters?

Mike T: What I'm finding with the 1475 is that as they get resharpened, the blade gets smaller around the edges, and they seem to work better with a Zenoah - allowing more rpm. When I work the prop initially, I leave a little extra blade to allow resharpening - so yours might benefit from a judicious reduction in size starting beside the tongue and going 1/2 way around the curve at the tip. More rpm with the same pitch should yield more speed (up to the point of excessive slip). The pliers are good for putting the cup in the edges. The block is a little trickier to use because the prop moves each time you tap on it. I made a modified 280 that was a cleaver-style (more constant radius) and it was real pretty but didn't work too well, not sure why.

Mike Kolder: Does this

info pertain to our gauges? rcboat.com/febtech.htm Never seen the Hughey

gauge. 70% sounds like a good distance to measure but it wont measure the

tongue. Wish I could download the tables. (See Link)

Mike T: I believe

the Hughey gauge works a little differently - you set a specified amount of

displacement and it tells how many degrees you turn the prop to displace that

far. Taking that number of degrees to their tables allows you to find the pitch.

Apache Bob: I bought a prop from Andy Brown. It is a 1475 it came with a 6.9 pitch. Couldn't pull rpms so I sent it back he changed it to 6.3 still no good. I have an apache 56" with a pro mod from WWH. Any suggestions on what to do with this prop? I'm a newbie so please don't get to technical, I'm running a Prather 280 now that was slightly modified. I know there is more there I just need help finding the right prop.

Butch T: Hi Bob, Try a modified 482.

Mike T: Is the engine a Homelite? If so, save the prop until you get a smaller boat with a modded Zenoah, it would be a charm for that. A 280 or a trimmed down Octura 482 might be better for what you have now.

Mike Kolder: Your not going to get the speed a 45" hull would do with your hull, and thats what size hull that prop was designed to push. Make a duplicator mold of it & sell, & mod your own 275 or 280. Nice all around prop. Or save it for the future. I cant afford to ruin a $70 prop so I sold mine to Riph after making molds. How fast did you go with the 280? If youre doing upper 40's with your set up, I would be happy. Does Andy square the tips now? I hear this is his new profile for the 1475.

Apache Bob: Thanks guys, I'll keep it if you think it would work on one of Eddy's new cats with a M&D hybrid???

Mike T: The AB-1475 is an excellent prop for a hot cat.

Scroll down to access the Pitch Conversion Tables and how to use pitch gauge and tables

With the above information Dave (Mobil Dave) made this tool. Congratulations Dave.

© 2000 - Carlos Andrade