Just for Fun Demo

Hot Rods created the topic: Just for Fun Demo

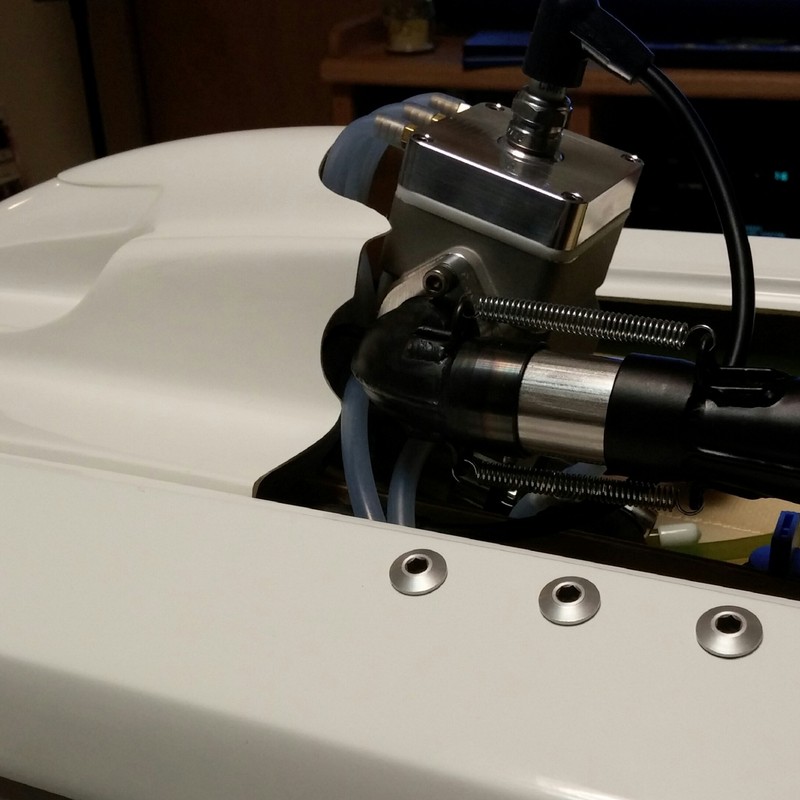

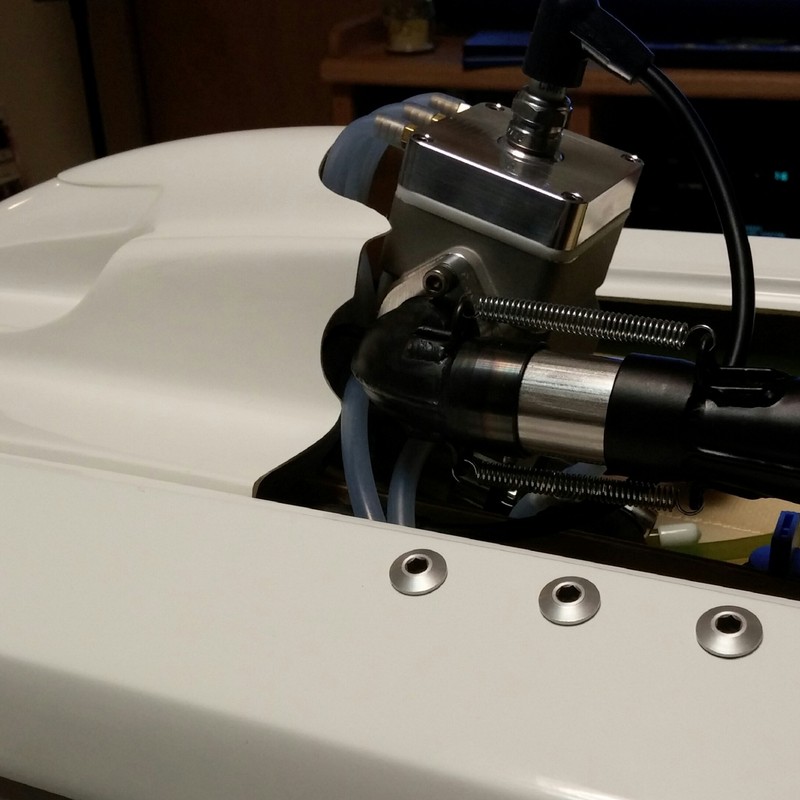

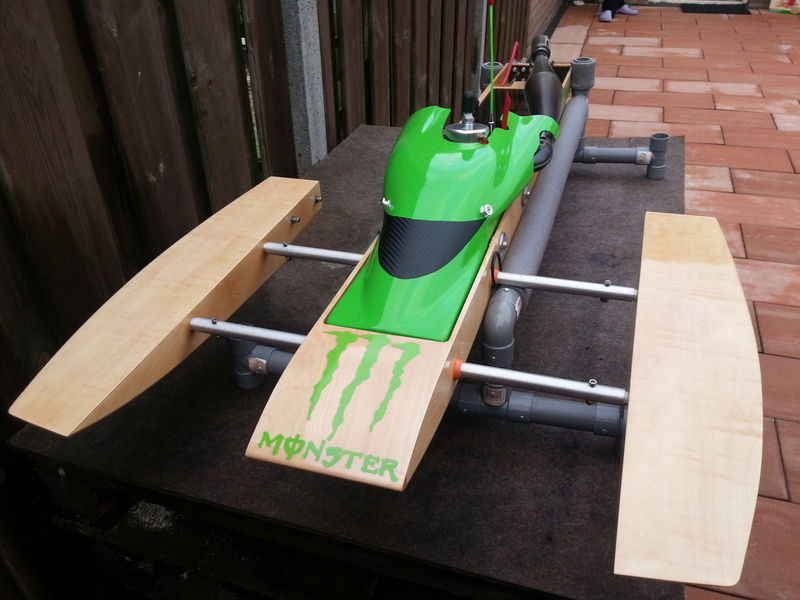

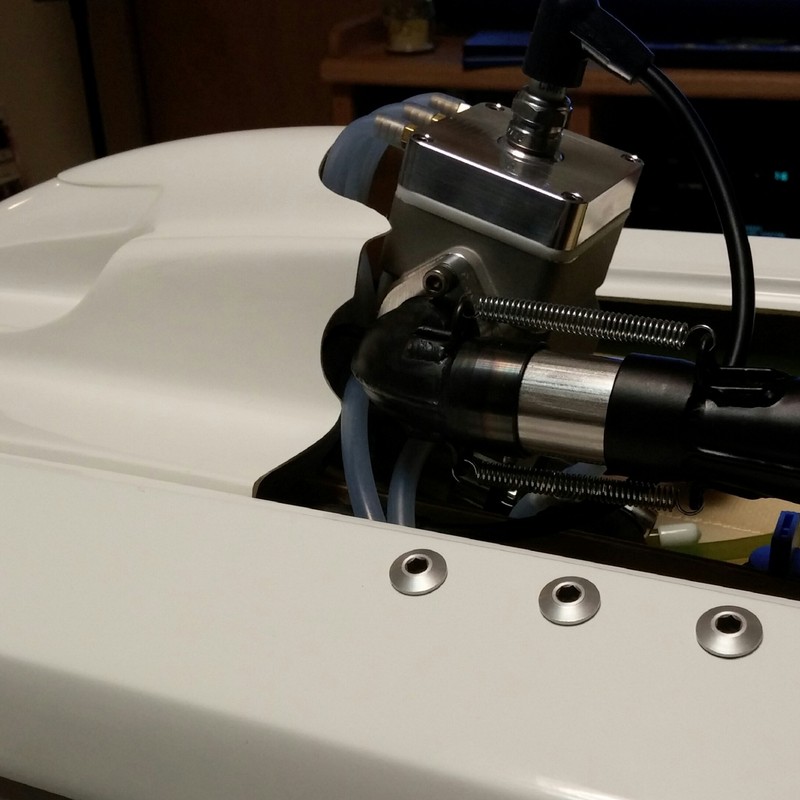

We thought it might be interesting to show a little comparison of throttle response between a conventional ignition/flywheel engine, and one with a very light rotational mass, Power Spark system. While we are VERY happy with the response of all our engines ( water and static ), I think the difference is quite apparent. These two engines are very similar in most ways. Apart from the J&G being a sleeved motor and down 3ccs; they both have 29mm. stroke, are ported almost identically, have the same compression ratio ( smaller chamber and displacement on the J&G ), timed within 5 degrees intake - rest of ports the same, both reciprocating assemblies are light ( the MK hybrid is slightly heavier, but has a heavier air cooled crank ), both identical carbs and intake, and the pipes are tuned to the same length, with the hybrid having a slightly larger diameter stinger to keep back pressure reasonable with the larger displacement. While the MK is running on our custom ign. map, at the RPM levels in the vids, the timing is very close. So power aside, the major difference to throttle response is the J&G has a roughly 290 gram flywheel/pulley, and the hybrid has a 67 gram flywheel/pulley. Add the magnetic drag of the three large magnets on the conventional flywheel to the mix. As well as having quick response for getting on load quickly, it's especially good to have a motor that shuts down so quickly when things go bad. The throttle inputs on both these motors was at the most, 1/4 blurps.

Anyway, this was fun to run a little fuel.

I think it's fixed. Thanks Pete!

Anyway, this was fun to run a little fuel.

I think it's fixed. Thanks Pete!

Last edit: 11 years 7 months ago by Hot Rods.

Please Log in or Create an account to join the conversation.

- Hot Rods

-

Topic Author

Topic Author

- Offline

- Posts: 164

- Karma: -5

- Thank you received: 36

SRI Motorsports replied the topic: Just for Fun Demo

Peter Somers

SRI Motorsports

Lazer 40 LSG27 + LSG36 SAW

Please Log in or Create an account to join the conversation.

- SRI Motorsports

-

- Offline

- Posts: 61

- Thank you received: 7

coppo65 replied the topic: Just for Fun Demo

Great work guys always thinking outside the square , that k30 sounds wicked, keep up the good work thanks for sharing

Andrew

Andrew

GO HARD OR GO HOME !!!!!

Please Log in or Create an account to join the conversation.

- coppo65

- Offline

- Posts: 21

- Thank you received: 1

Motorboater replied the topic: Just for Fun Demo

I agree with Coppo. I'll never need that level of setup, but have to admit that the k30 does sound pretty angry. What sort of fuel mix do you run on something like that?

Please Log in or Create an account to join the conversation.

- Motorboater

-

- Offline

- Posts: 46

- Karma: 2

- Thank you received: 4

SRI Motorsports replied the topic: Just for Fun Demo

Dad is probably still sleeping so maybe I can help out. All our engines run on 110oct race fuel with 8oz of HP2 and in our sleeved engines we run 10oz. We may in the future put everything on 8oz depending on close inspections internally. This spring test sessions will determin that. I personally noticed the 10oz smoked way more then 8oz, maybe it was my mind playing games with me. Next in the line up for needle tuning...

Peter Somers

SRI Motorsports

Lazer 40 LSG27 + LSG36 SAW

Last edit: 11 years 7 months ago by SRI Motorsports.

Please Log in or Create an account to join the conversation.

- SRI Motorsports

-

- Offline

- Posts: 61

- Thank you received: 7

Whiplon replied the topic: Just for Fun Demo

The K30 sound pretty good.

Nice build.

Nice build.

Please Log in or Create an account to join the conversation.

- Whiplon

-

- Offline

- Posts: 24

- Thank you received: 2

Hot Rods replied the topic: Just for Fun Demo

Thanks for the kind words guys. After that crazy winter we had, it sure helps to hear them come to life again. They will lean out on the water, but the plugs came out very black after these few runs. The concentration this spring will be on shaking down Pete's new ride. The 30.5 SRI Pioneer has plenty of bottom end grunt to begin with, and the Power Spark allows the same ultra light rotational mass as the MK hybrid. That, together with multiple buttons/props to try, will fill our spring/summer. LOL, I hope Andy set those Lazer 40 rails in good and strong, to handle the new "weapon". Just kiddin.

Please Log in or Create an account to join the conversation.

- Hot Rods

-

Topic Author

Topic Author

- Offline

- Posts: 164

- Karma: -5

- Thank you received: 36

Andrew Lane replied the topic: Just for Fun Demo

Peter you and dad coming out to Coby

For the fun run again this year ?

cheers

For the fun run again this year ?

cheers

Please Log in or Create an account to join the conversation.

- Andrew Lane

-

- Offline

- Posts: 22

- Thank you received: 4

SRI Motorsports replied the topic: Just for Fun Demo

Hey Andrew. I am planning to go. I need to check the dates with work and have to see if dad will be avail. Was good fun all day long.

Peter Somers

SRI Motorsports

Lazer 40 LSG27 + LSG36 SAW

Please Log in or Create an account to join the conversation.

- SRI Motorsports

-

- Offline

- Posts: 61

- Thank you received: 7

Hot Rods replied the topic: Just for Fun Demo

Hey Andrew. Pete will need to take time from work again, but we are planning on making it this year as well. Pretty little town to hang out and make some spray and noise for the kids of all ages. It'd be great to see ya there.

Please Log in or Create an account to join the conversation.

- Hot Rods

-

Topic Author

Topic Author

- Offline

- Posts: 164

- Karma: -5

- Thank you received: 36

Time to create page: 0.095 seconds