Brand New replacement RCMK crankshaft

scottcmb created the topic: Brand New replacement RCMK crankshaft

Has anyone bought a replacement rcmk crankshaft and found it has excessive big end play IE a big amount of rocking play on the big end bearing ( and im not talking about sideways float either) and also if you hold the conrod and pull it up and down you feel about a .001thou movement.

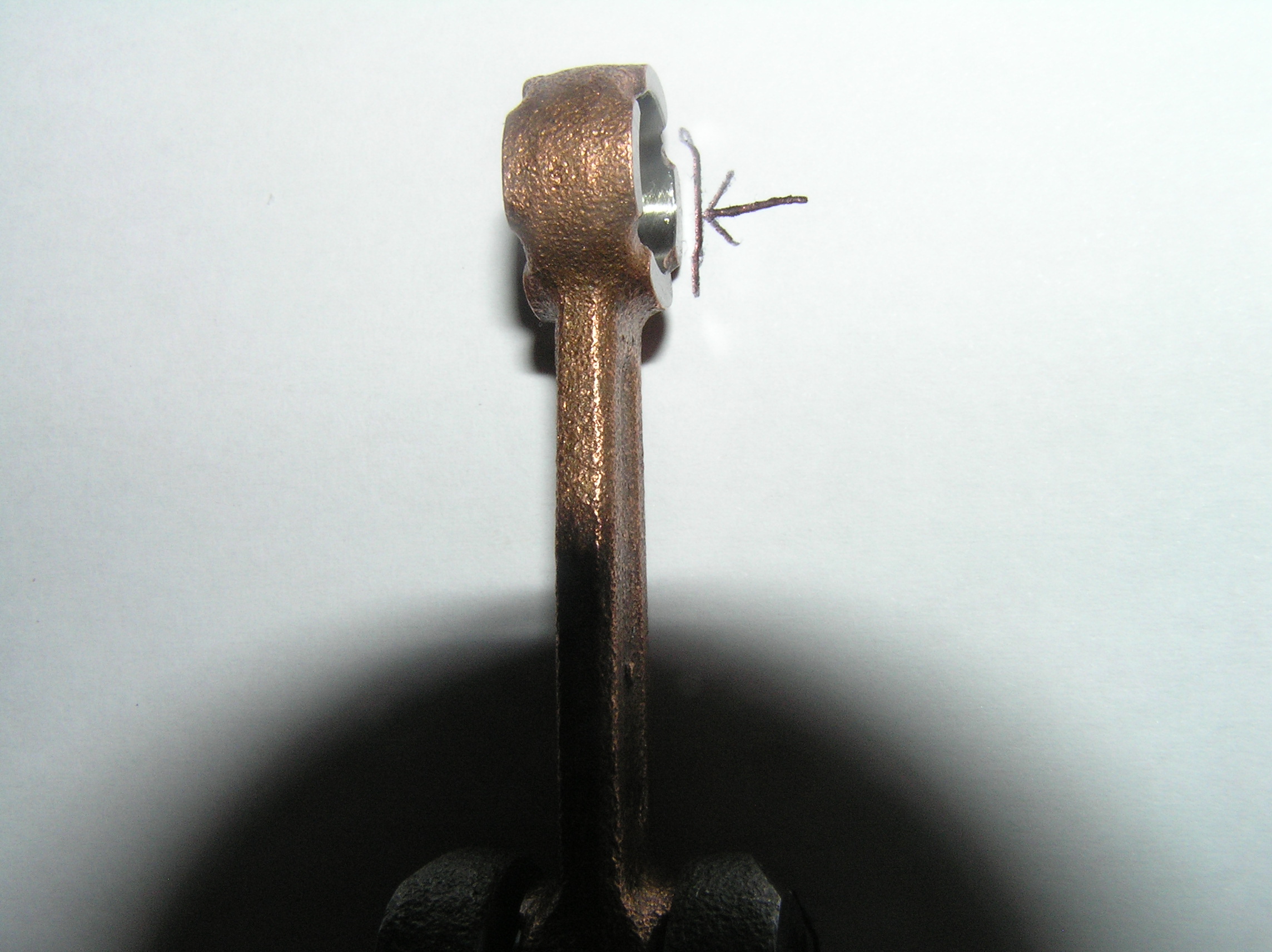

Also the small end is not centre to the whole rod. below is a pic of the rocking play at the bigend

I am also having big trouble getting RCMK to understand the problem with it and wanting it replaced. But it is difficult because of the language barrier.

Also the small end is not centre to the whole rod. below is a pic of the rocking play at the bigend

I am also having big trouble getting RCMK to understand the problem with it and wanting it replaced. But it is difficult because of the language barrier.

Last edit: 15 years 1 month ago by scottcmb. Reason: spelling

Please Log in or Create an account to join the conversation.

- scottcmb

- Offline

- Posts: 8

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- scottcmb

- Offline

- Posts: 8

- Thank you received: 0

Last edit: 15 years 1 month ago by scottcmb.

Please Log in or Create an account to join the conversation.

- scottcmb

- Offline

- Posts: 8

- Thank you received: 0

scottcmb replied the topic: Re: Brand New replacement RCMK cranshaft

I have also compared this crank to 2 other crankshafts i have ( my original standard crank and a stroker crank) and they are good and nowhere as bad as this new crankshaft i was sent direct from RCMK

Please Log in or Create an account to join the conversation.

- scottcmb

- Offline

- Posts: 8

- Thank you received: 0

QDRevenger replied the topic: Re: Brand New replacement RCMK crankshaft

Heya Scott,

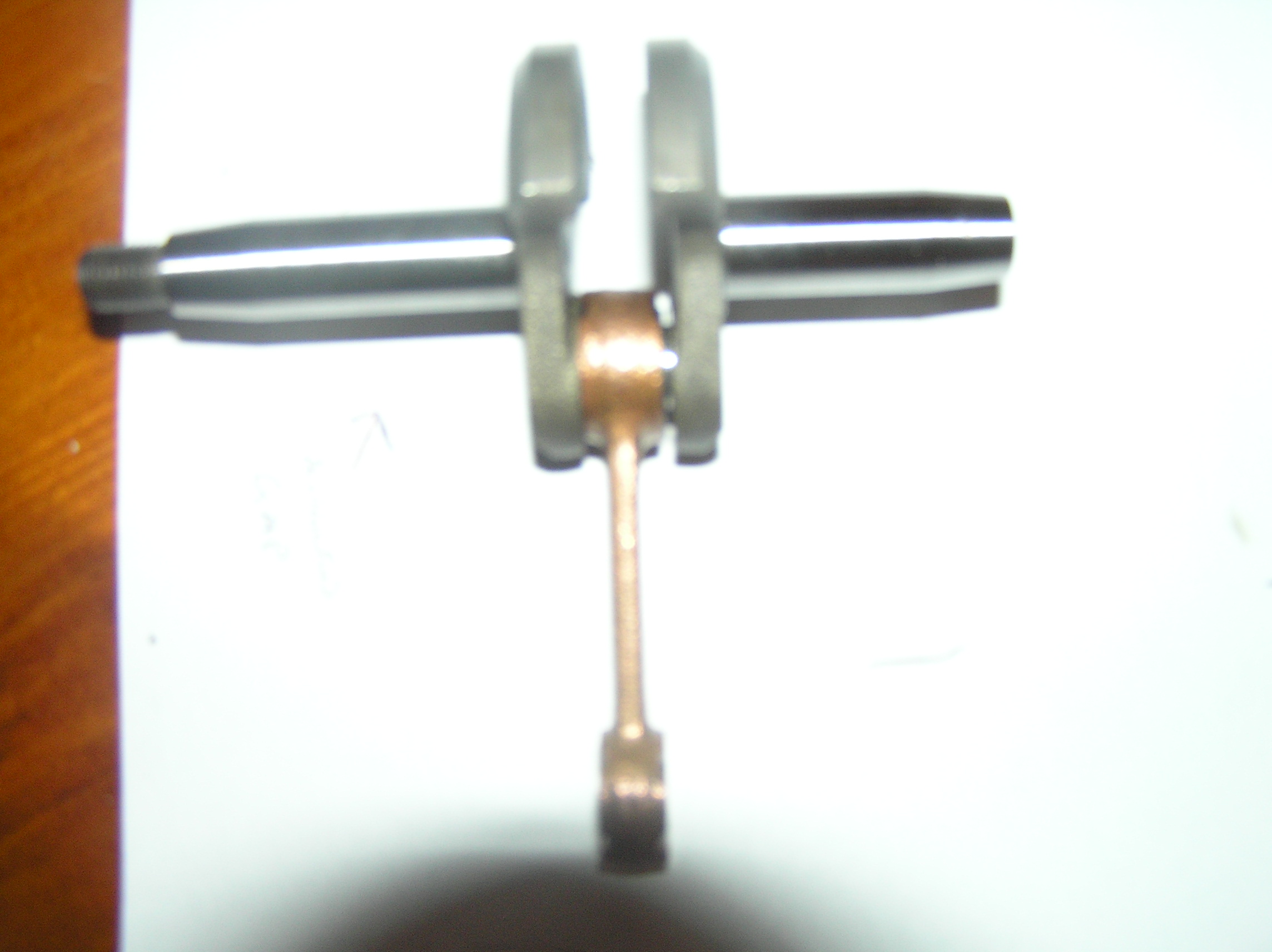

Having seen this crank in person as we were changing out a 1mm Stroker crank to a stock stroke crank to test some theories. I was dissapointed to see the amount of what I have labeled on the pic below as "side rock" of the bigend bearing which was around 0.5mm and the "big end play" at least 0.001" Not having played too much with the RCMK cranks, only a 1mm stroker myself was surprised. I would be throwing out a Zenoah crank with this much play, yet the RCMK one came like this new. Mr Park can be testing at best to get him to understand an issue.

Scott S, is this normal of an RCMK crank? Or is this an exception? Seems to me like the bottom end bearing journal in the rod has been machined too big and both the small end and bottom end look bored offset and not square to the forging.

QDRevenger.

Having seen this crank in person as we were changing out a 1mm Stroker crank to a stock stroke crank to test some theories. I was dissapointed to see the amount of what I have labeled on the pic below as "side rock" of the bigend bearing which was around 0.5mm and the "big end play" at least 0.001" Not having played too much with the RCMK cranks, only a 1mm stroker myself was surprised. I would be throwing out a Zenoah crank with this much play, yet the RCMK one came like this new. Mr Park can be testing at best to get him to understand an issue.

Scott S, is this normal of an RCMK crank? Or is this an exception? Seems to me like the bottom end bearing journal in the rod has been machined too big and both the small end and bottom end look bored offset and not square to the forging.

QDRevenger.

Please Log in or Create an account to join the conversation.

- QDRevenger

- Offline

- Posts: 66

- Thank you received: 0

marc replied the topic: Re: Brand New replacement RCMK crankshaft

I just checked one that I have here. A standard RCMK crank and it measured 0.010" (0.25mm) of what you call "side rock" and 0 endplay. As good as Zenoah cranks I've seen by the "feel" of it. Never actually stopped to measure this.

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

scottcmb replied the topic: Re: Brand New replacement RCMK crankshaft

Marc wrote:If you look closely at the first pic i posted you can see the line i scribed onto the paper with a pen when the conrod was hard to the right, then keeping the whole crankshaft and conrod perfectly still i rocked the conrod small end over as far left as it would go and took the picture with my camera.

You can see both small and big end as a reference in the picture to show actually how much rock there is, and i can tell you it is WAY more than 10 thou.

It is actually closer to 35-40 thou movement or 1-1.5mm movement.

THIS DOES NOT MAKE ME A HAPPY CHAPPY TO RECEIVE THIS AS A BRAND NEW ITEM!!!!

You can see both small and big end as a reference in the picture to show actually how much rock there is, and i can tell you it is WAY more than 10 thou.

It is actually closer to 35-40 thou movement or 1-1.5mm movement.

THIS DOES NOT MAKE ME A HAPPY CHAPPY TO RECEIVE THIS AS A BRAND NEW ITEM!!!!

Please Log in or Create an account to join the conversation.

- scottcmb

- Offline

- Posts: 8

- Thank you received: 0

scottcmb replied the topic: Re: Brand New replacement RCMK crankshaft

QDRevenger wrote:

Thanks for putting the squigglies on the pic for me Andrew!! and adding weight to what i am asking on here seeing people on here dont know me!!!!

Scott

Thanks for putting the squigglies on the pic for me Andrew!! and adding weight to what i am asking on here seeing people on here dont know me!!!!

Scott

Last edit: 15 years 1 month ago by scottcmb.

Please Log in or Create an account to join the conversation.

- scottcmb

- Offline

- Posts: 8

- Thank you received: 0

marc replied the topic: Re: Brand New replacement RCMK crankshaft

scottcmb wrote:

I just posted what I got from checking the only RCMK crank I have here on hand. Mine is fine as far as I'm concerned. If yours is that much out of whack, I would have them replace it.

I just posted what I got from checking the only RCMK crank I have here on hand. Mine is fine as far as I'm concerned. If yours is that much out of whack, I would have them replace it.

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Scott replied the topic: Re: Brand New replacement RCMK crankshaft

Really all I can offer is the personal observation that RCMK has what appears to be at times enough inconsistencies in quality control of Min/Max specs that some rods have very little side to side rock while others seem a tad loose like you find in an engine after some hours of hard running.

In a conversation with Jim Allen on JRCBD, he stated to me in taking apart RCMK cranks he has noted rods big end diameters vary as much as .0008" which would account for the side rock you very well may be experiencing ?

Now as for the hole of bearing journal not being centered within forging, that is pretty typical and not something I would worry about.

I can tell you of all the RCMK's I personally race, Dozens more done for others have only heard and seen one failure of the big end of rod. It was on one of my own that had noted was really tight having free rotation but minimal side rock.

It had turned bottom end of rod Blue/Purple after some testing in the 19K+ rpm range.

Never came apart but was scrapped after finding it.

Right now don't have any engines opened up on the bench but will say in a rough guess that if you MAKE SURE big end is not sliding back and forth while side rocking rod as drawn .... .010" - .030" lateral movement at rods small end is pretty typical even in Zenoahs too.

You do need to understand that the tighter fit becomes on either end of rod, greater become the bearing loads if any misalignment of bore not being a perfect 90* to cranks C/L ... Tilting of piston within bore etc.

While tighter bearing tolerances having the reciprocating parts more held in perfect alignment, greater becomes precision the entire engine must be built to keeping it all straight square and true

** Not defending RCMK's manufacturing discrepancies that we all know exist, but simply stating you may very well be picking apart issues that are not really an issue in the long run.

What I would do is document what you feel is wrong, share that with Mr.Park at RCMK. If he does nothing don't sweat it and run the snot out of the engine.

If it does fail down the road you have a paper trail of your concerns that gives you creditability in having RCMK make it right.

Being one who has been in the trenchs dealing with RCMK's teething pains over this past 2 years, can say RCMK as supported there product 110% never charging me a dime for faulty parts. Every time Mr.Park has shipped parts from Korea on his dime

and said if you need support we are here !!

What more can I say

In a conversation with Jim Allen on JRCBD, he stated to me in taking apart RCMK cranks he has noted rods big end diameters vary as much as .0008" which would account for the side rock you very well may be experiencing ?

Now as for the hole of bearing journal not being centered within forging, that is pretty typical and not something I would worry about.

I can tell you of all the RCMK's I personally race, Dozens more done for others have only heard and seen one failure of the big end of rod. It was on one of my own that had noted was really tight having free rotation but minimal side rock.

It had turned bottom end of rod Blue/Purple after some testing in the 19K+ rpm range.

Never came apart but was scrapped after finding it.

Right now don't have any engines opened up on the bench but will say in a rough guess that if you MAKE SURE big end is not sliding back and forth while side rocking rod as drawn .... .010" - .030" lateral movement at rods small end is pretty typical even in Zenoahs too.

You do need to understand that the tighter fit becomes on either end of rod, greater become the bearing loads if any misalignment of bore not being a perfect 90* to cranks C/L ... Tilting of piston within bore etc.

While tighter bearing tolerances having the reciprocating parts more held in perfect alignment, greater becomes precision the entire engine must be built to keeping it all straight square and true

** Not defending RCMK's manufacturing discrepancies that we all know exist, but simply stating you may very well be picking apart issues that are not really an issue in the long run.

What I would do is document what you feel is wrong, share that with Mr.Park at RCMK. If he does nothing don't sweat it and run the snot out of the engine.

If it does fail down the road you have a paper trail of your concerns that gives you creditability in having RCMK make it right.

Being one who has been in the trenchs dealing with RCMK's teething pains over this past 2 years, can say RCMK as supported there product 110% never charging me a dime for faulty parts. Every time Mr.Park has shipped parts from Korea on his dime

and said if you need support we are here !!

What more can I say

2 stroke Engine Tech of 30+ years, Prop tweeker, Chronic tinkerholic, Home of Motor Heads RC Racing Engines ...

8 time NAMBA National 6 lap heat racing record holder.

Last edit: 15 years 1 month ago by Scott.

Please Log in or Create an account to join the conversation.

- Scott

- Offline

- Devoted Enthusiast ... MGB Technical advisor

- Posts: 1254

- Karma: 27

- Thank you received: 23

Time to create page: 0.083 seconds