The perfect reliable rudder linkage? What do you find best?

bentoad replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

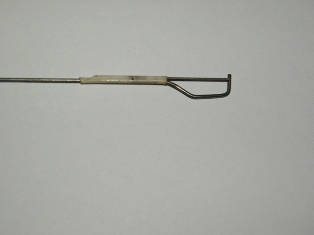

]I make my own . Quick and simple.I

a boat that does 100 yds in 2.8 sec..Never failed .I also use it on my planes

Last edit: 14 years 7 months ago by bentoad.

Please Log in or Create an account to join the conversation.

- bentoad

- Offline

- 100 YARDS IN ---2.8 SECONDS

- Posts: 12

- Thank you received: 0

Craig Dickson replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Hi Bentoad

If my maths is correct, I figure that your boat is doing top side of 73 miles per hour! In my book that is very fast.

In respect of your boat referred to could we have a little more information about it?

What kind of hull is it?

How big is it?

How heavy is it?

What engine powers it?

Is it a boat that has to go through multiple sharp (full rudder) turns or mainly designed for flat out straight line speed?

Would you consider your linkage suitable for a 50” long, heavy surface driven mono hull fitted with a 26cc gas engine with a high power rudder servo and a substantial rudder?

Cheers

Craig

If my maths is correct, I figure that your boat is doing top side of 73 miles per hour! In my book that is very fast.

In respect of your boat referred to could we have a little more information about it?

What kind of hull is it?

How big is it?

How heavy is it?

What engine powers it?

Is it a boat that has to go through multiple sharp (full rudder) turns or mainly designed for flat out straight line speed?

Would you consider your linkage suitable for a 50” long, heavy surface driven mono hull fitted with a 26cc gas engine with a high power rudder servo and a substantial rudder?

Cheers

Craig

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Scott replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Personally feel laying 2 rods side by side with a wheel collar or two is just CHEEZY !!

It adds much more weight to the assembly having the hull/engine vibration present shake the linkage even more adding wear and tear to both ends of rods connection points, servo gears as well get more wear !

Also DON'T like ball link connections on servo arm/horns, doing so places an added rotational twist to the arm as load/resistance is applied. Keeping control rod on a pin clevis threw hole in arm eliminates the rotation effect.

* Do make ALL my linkages from a SINGLE rod, either 2-56 or 4-40 size. Sullivan "Gold-N-Clevis" silver soldered onto one end, threaded on other end for connection to carb or rudder arms. ( At control surface end of linkage I do use ball link types.

Spring loaded quick disconnect for carb and a H.D. captive swivel with a 4/40 bolt on rudder.

It adds much more weight to the assembly having the hull/engine vibration present shake the linkage even more adding wear and tear to both ends of rods connection points, servo gears as well get more wear !

Also DON'T like ball link connections on servo arm/horns, doing so places an added rotational twist to the arm as load/resistance is applied. Keeping control rod on a pin clevis threw hole in arm eliminates the rotation effect.

* Do make ALL my linkages from a SINGLE rod, either 2-56 or 4-40 size. Sullivan "Gold-N-Clevis" silver soldered onto one end, threaded on other end for connection to carb or rudder arms. ( At control surface end of linkage I do use ball link types.

Spring loaded quick disconnect for carb and a H.D. captive swivel with a 4/40 bolt on rudder.

2 stroke Engine Tech of 30+ years, Prop tweeker, Chronic tinkerholic, Home of Motor Heads RC Racing Engines ...

8 time NAMBA National 6 lap heat racing record holder.

Please Log in or Create an account to join the conversation.

- Scott

- Offline

- Devoted Enthusiast ... MGB Technical advisor

- Posts: 1254

- Karma: 27

- Thank you received: 23

isuzudude replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I use ball links on my Helis and have never had an issue... but putting the force of water on the control surfaces makes me a little weary... just my one cent worth....

Please Log in or Create an account to join the conversation.

- isuzudude

- Offline

- Posts: 574

- Karma: 5

- Thank you received: 4

bentoad replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

THe boat in the video was doing a standing start It wae verified with a castle Ice data logging ESC. I bought that boat from goodwill for $4.50 I went through 4 months of reshapping the hull and a dozen of so called fast brushless motors. I have some killer footage of the boat getting air and diving out of sight and blasting back up like a polaris sub.It crashed so many times I can't count.I ended up with a 3656 brned out can that I rewound and made a water jacket for the motor and speed control for I did a thread in rc groups under rc racing boats speed called mosquito craft 100 yds in 2.8 sec (some good footage and pics} If you go back to my video and look at some of bentoads videos I have some good videos I had 85 but when you tubemade its change they lost all but 27.Back to the subject the control arm is all one piece and the keeper can be any strength you want. can be shrink wrapped glued or soldered. easy to make., never had a failure.I had a black jack 61.5" over 20 lbs with a sail winch servo .090 piano wire top speed with my modified ZENOAH. I now haVE A 47" CAT WITH THE RUDDER EXTENDED 5 "

Last edit: 14 years 7 months ago by bentoad.

Please Log in or Create an account to join the conversation.

- bentoad

- Offline

- 100 YARDS IN ---2.8 SECONDS

- Posts: 12

- Thank you received: 0

Time to create page: 0.088 seconds