The perfect reliable rudder linkage? What do you find best?

Craig Dickson created the topic: The perfect reliable rudder linkage? What do you find best?

Hi folks.

When it comes to the commercially available connections for the rudder linkage, I have never felt comfortable with what is available. I decided to make my own and so far they have stood the test of time.

I will be interested to know what you think.

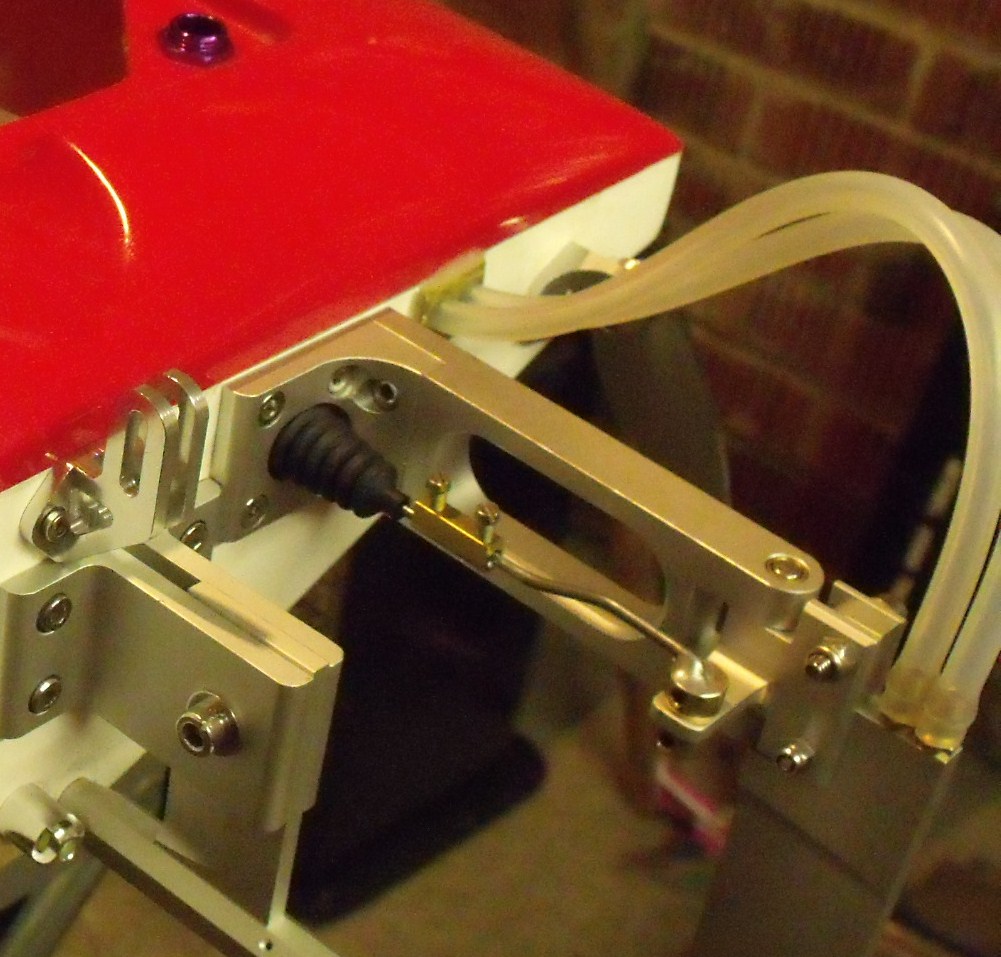

For the link to the alloy tiller arm I used piano wire bent at 90 degrees and incorporated two brass sleeves with a top collet all soft soldered together as per this image. The thicker brass sleeve was slightly over size to the hole in the tiller arm. I opened up the hole in the tiller arm just enough to allow for free movement but with minimal play.

The big advantage is that the bottom retaining collet has its grub screw seating into brass with the steel inner wire there for strength. With a bit of locktite on the bottom collet grub screw, it is very reliable and strong.

The set up also ensures square seating of the components to minimise friction and servo battery drain.

The second image shows the same principle applied to the rudder servo arm.

The third image shows the linkage connected at the transom with easy adjustment to the rod length via the twin screwed electrical connection.

What do you think? Is it worth the fiddling and soldering?

Cheers

Craig

When it comes to the commercially available connections for the rudder linkage, I have never felt comfortable with what is available. I decided to make my own and so far they have stood the test of time.

I will be interested to know what you think.

For the link to the alloy tiller arm I used piano wire bent at 90 degrees and incorporated two brass sleeves with a top collet all soft soldered together as per this image. The thicker brass sleeve was slightly over size to the hole in the tiller arm. I opened up the hole in the tiller arm just enough to allow for free movement but with minimal play.

The big advantage is that the bottom retaining collet has its grub screw seating into brass with the steel inner wire there for strength. With a bit of locktite on the bottom collet grub screw, it is very reliable and strong.

The set up also ensures square seating of the components to minimise friction and servo battery drain.

The second image shows the same principle applied to the rudder servo arm.

The third image shows the linkage connected at the transom with easy adjustment to the rod length via the twin screwed electrical connection.

What do you think? Is it worth the fiddling and soldering?

Cheers

Craig

Last edit: 14 years 8 months ago by Craig Dickson.

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Woodie replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Looking very good, Craig.

I will consider using the same solutions on my two sterndrives when time comes.

What is the thickness of the piano string?

Is it a simple tin soldering? Did you bore a hole for the piano string at the soldering?

Can you recommend where to buy other parts?

Cheers!

Woodie.

I will consider using the same solutions on my two sterndrives when time comes.

What is the thickness of the piano string?

Is it a simple tin soldering? Did you bore a hole for the piano string at the soldering?

Can you recommend where to buy other parts?

Cheers!

Woodie.

Last edit: 14 years 8 months ago by Woodie.

Please Log in or Create an account to join the conversation.

- Woodie

-

Craig Dickson replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Hi Woodie

Thanks for your quick reply. The piano wire is 2mm thick. Stainless steel bike spokes are an alternative though I find them less tensile.

The soldering was relatively simple though not what I'd call tin soldering. Ultra Clean components, the appropriate flux and just enough heat in the right place to have the solder run.

The other parts I got from my local model shop. I always carry plenty of brass tubes and brass collets as they are such useful things to have at hand.

Cheers

Craig

Thanks for your quick reply. The piano wire is 2mm thick. Stainless steel bike spokes are an alternative though I find them less tensile.

The soldering was relatively simple though not what I'd call tin soldering. Ultra Clean components, the appropriate flux and just enough heat in the right place to have the solder run.

The other parts I got from my local model shop. I always carry plenty of brass tubes and brass collets as they are such useful things to have at hand.

Cheers

Craig

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

marc replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Very nice linkage and looks bulletproof. I think if it give you piece of mind it's definitely worth the time and effort to make them.

Me, I've been using the HD Dubros for years now without failure, so it's hard to convince me to change! I use 2 threaded rods (1 per clevis) and joint them with a wheel collar. Similar to what you're doing with that electrical connector. I have to find some of those!

I use 2 threaded rods (1 per clevis) and joint them with a wheel collar. Similar to what you're doing with that electrical connector. I have to find some of those!

Here's the Dubro link, just so you know what I'm referring to: www.sigmfg.com/IndexText/DUB878.html

Me, I've been using the HD Dubros for years now without failure, so it's hard to convince me to change!

Here's the Dubro link, just so you know what I'm referring to: www.sigmfg.com/IndexText/DUB878.html

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Craig Dickson replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Thanks for the link to the Dubro linkage Marc. I have to say that I am a big fan of the Dubro products as they are very well made.

Cheers

Craig

Cheers

Craig

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Steve Seebold replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Nice looking linkage, but the pin through the hole will eventually knock the hole out of shape. I think the best is a Traxas ball linkage fastened solidly to your steering arm with a 4-40 screw and let the ball joint be the swivel.

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

dazzido replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Yes got to agree with Steve on this one Craig eventually your rudder fixing will go egg shaped,i use the brass ball fitted with a nut and the plastic fitting attached to the rod.When it wears simply undo the nut and replace the ball and plastic fitted to the rod,very cheap and simple.regards Darren p.s.just had a problem on my boat where the boat was going from side to side rocking,when i,ve diagnosed it it was the servo through using cheap ones,it had loads of play in it so was chattering left to right,fixed by replacing the servo.You could eventually suffer from this when that linkage wears.just a thought m8 for you to keep in mind.

Last edit: 14 years 8 months ago by dazzido.

Please Log in or Create an account to join the conversation.

- dazzido

- Offline

- Posts: 71

- Thank you received: 1

Craig Dickson replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I could not make out whether Steve was referring to my home made linkage or the Dubro one that Marc included a link to.

However regardless of that I accept that eventually both linkages could cause the tiller arm or rudder arm hole to wear and perhaps go a bit egg shaped.

The Key point in respect of my opening topic images is that my linkage is designed to have minimal components that can fail. Also with my suggested set up, you have no need to worry about whether wear and tear could place the system close to unexpected failure. How can you tell when an alternative ball joint linkage has sufficient play to potentially fail?

If play does develop within the moving components of my set up, it is easy to monitor without removing the linkages for inspection. There is a BIG margin of safety unlike some of the more intricate multiple component linkages. That margin of safety includes the fact that the brass faced + steel pin through the hole is substantially larger in diameter than many of the commercially available alternatives.

I have to say that after many hours of use, wear on the arm holes has yet to become an issue.

For me personally my absolute key requirement of a rudder linkage is that it is as bullet proof as possible such that if my boat should crash, the rudder linkage will not be a cause of that incident.

I appreciate your input folks.

Cheers

Craig

However regardless of that I accept that eventually both linkages could cause the tiller arm or rudder arm hole to wear and perhaps go a bit egg shaped.

The Key point in respect of my opening topic images is that my linkage is designed to have minimal components that can fail. Also with my suggested set up, you have no need to worry about whether wear and tear could place the system close to unexpected failure. How can you tell when an alternative ball joint linkage has sufficient play to potentially fail?

If play does develop within the moving components of my set up, it is easy to monitor without removing the linkages for inspection. There is a BIG margin of safety unlike some of the more intricate multiple component linkages. That margin of safety includes the fact that the brass faced + steel pin through the hole is substantially larger in diameter than many of the commercially available alternatives.

I have to say that after many hours of use, wear on the arm holes has yet to become an issue.

For me personally my absolute key requirement of a rudder linkage is that it is as bullet proof as possible such that if my boat should crash, the rudder linkage will not be a cause of that incident.

I appreciate your input folks.

Cheers

Craig

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Canadian Hot Rod RC Boats replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I believe Steve was referring to your linkage - I do same as Steve and use 4/40 Durbo ends with ball linkage

I also make ALL my linkage 1 piece and do not joint any with connectors (to me that electrical connector is where I see failure first.

I keep mine: one piece rods - straight without bends where possible (just takes thought before hand and some planning) - threaded both ends - 4/40 ball ends - if the 4/40 rod is long I will sleeve it with some carbon fiber rod over the 4/40

Your linkage is okay but I'm not fond of 2 piece rods, counting on 2mm set screw to hold linkage on (your collar screw) - 2/56 or ? (on your connector - actually 2 of them) - the bend in the rod - also bending some (some types not all are brittle and break easy if u bend them) stainless materials is not a good idea - I also do not see how you adjust the rod's length if needed...

I can see doing some of this (joining linkages) if I had a need to take apart all the time -- but I don't rarely need to pull steering linkage so it's one piece and straight and adjustable for minor changes

Just my 2 cents -- I'm away from home or I'd add some pics .....

I'm no expert like many 'pros' here and elsewhere - but I have never lost a boat from sterring failure.........

Cheers

Randy

Misty Creek RC Boats Canada Ltd.

I also make ALL my linkage 1 piece and do not joint any with connectors (to me that electrical connector is where I see failure first.

I keep mine: one piece rods - straight without bends where possible (just takes thought before hand and some planning) - threaded both ends - 4/40 ball ends - if the 4/40 rod is long I will sleeve it with some carbon fiber rod over the 4/40

Your linkage is okay but I'm not fond of 2 piece rods, counting on 2mm set screw to hold linkage on (your collar screw) - 2/56 or ? (on your connector - actually 2 of them) - the bend in the rod - also bending some (some types not all are brittle and break easy if u bend them) stainless materials is not a good idea - I also do not see how you adjust the rod's length if needed...

I can see doing some of this (joining linkages) if I had a need to take apart all the time -- but I don't rarely need to pull steering linkage so it's one piece and straight and adjustable for minor changes

Just my 2 cents -- I'm away from home or I'd add some pics .....

I'm no expert like many 'pros' here and elsewhere - but I have never lost a boat from sterring failure.........

Cheers

Randy

Misty Creek RC Boats Canada Ltd.

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Last edit: 14 years 8 months ago by Canadian Hot Rod RC Boats. Reason: spelling

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

marc replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

All suggestions on this thread are good and valid. As with many things, it usually boils down to personal preference. I can tell you all that I have been using the 2-piece linkage setups for several years now and have never had a failure. I try to use 2 wheel collars (when I can) to secure the two 4-40 rods together, having both rods overlapping each other a few inches. This overlap is a quick and easy place to adjust linkage length if required. On both ends I use the heavy duty Dubro clevis. I've used the HD ball links on some builds also and they do work great.

I build many boats per year and over the years I've standardized on this system. It just works for me and its very economical. I guess it depends on what you do with your boats too. I found that on my race boats this setup is great. If I bust a servo at a race I can take things apart and in no time get everything back together and adjusted between heats. As for the wear on the servo horns....it does happen, but quite honestly, it takes a while and if you're like me, you probably have a drawer full of left over servo horns! The more critical part is the control horn on the rudder...that one costs more...if you are to use a ball-link, that would be the place in my opinion.

The more critical part is the control horn on the rudder...that one costs more...if you are to use a ball-link, that would be the place in my opinion.

Just sharing my thoughts.

I build many boats per year and over the years I've standardized on this system. It just works for me and its very economical. I guess it depends on what you do with your boats too. I found that on my race boats this setup is great. If I bust a servo at a race I can take things apart and in no time get everything back together and adjusted between heats. As for the wear on the servo horns....it does happen, but quite honestly, it takes a while and if you're like me, you probably have a drawer full of left over servo horns!

Just sharing my thoughts.

"

Last edit: 14 years 7 months ago by marc.

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Time to create page: 0.147 seconds