The perfect reliable rudder linkage? What do you find best?

Ronald Olson replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I use the Du-Bro links like what Marc showed in the link but usually only at one end. The other end I like to have one that swivels when I can but I worry about those popping off at the wrong time. Sullivan has some that are captured with a spring-loaded sleeve.

sullivanproducts.com/ContSysAccMainFrame.htm

I'm glad that I just went onto the Sullivan site as I see that they have some new anodized ones! Oh boy, more bling!

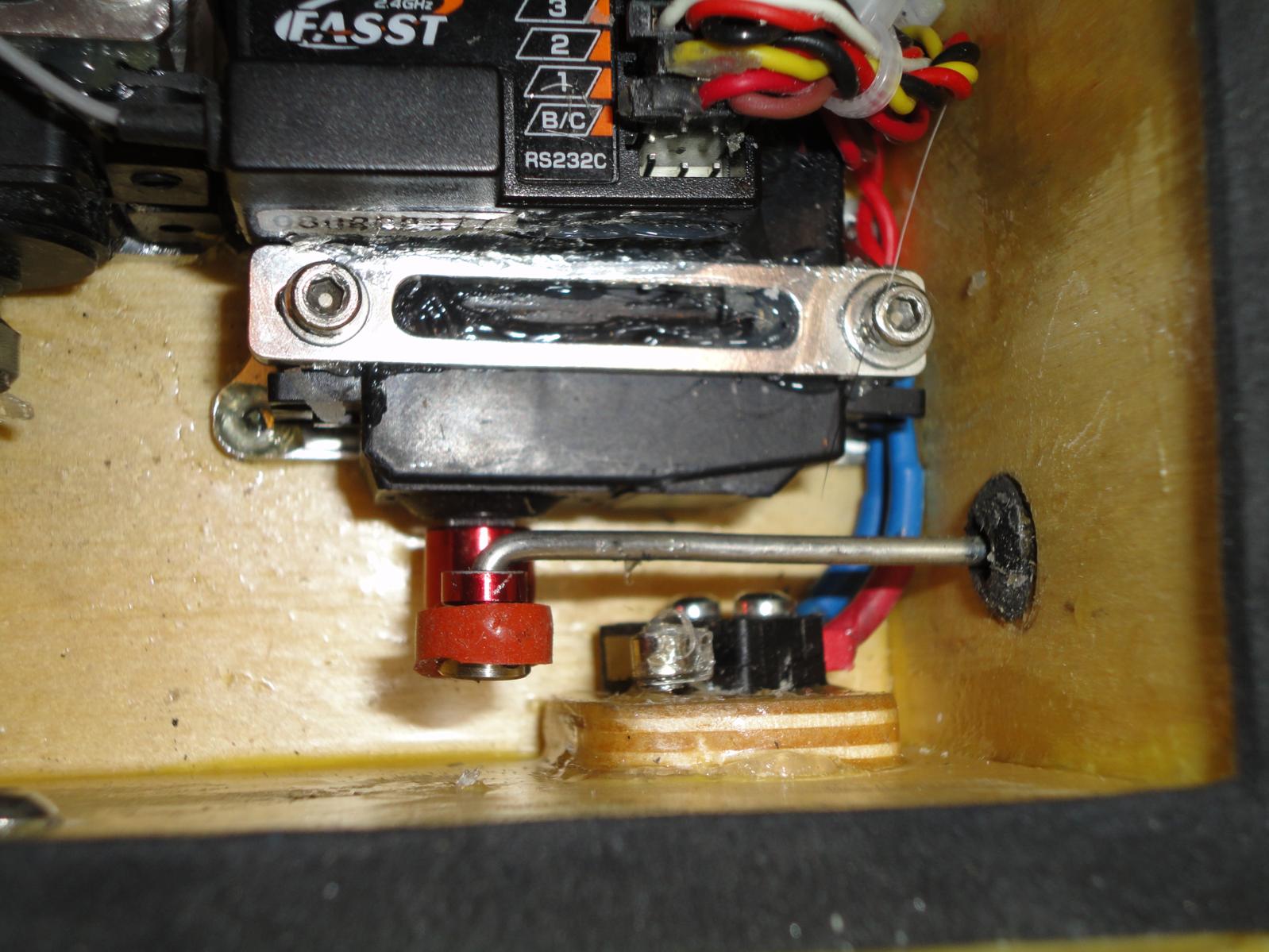

I really need to go back to using 2 pieces of piano wire with the wheel collars as it's a hassle to take out a radio box when I need to with single rods.

sullivanproducts.com/ContSysAccMainFrame.htm

I'm glad that I just went onto the Sullivan site as I see that they have some new anodized ones! Oh boy, more bling!

I really need to go back to using 2 pieces of piano wire with the wheel collars as it's a hassle to take out a radio box when I need to with single rods.

Please Log in or Create an account to join the conversation.

- Ronald Olson

- Offline

- Posts: 177

- Karma: 8

- Thank you received: 12

Craig Dickson replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I agree (with Marc) that valid points have been made and yes it is much down to personal preference. Thanks all of you for your comments so far.

I like the concept of the ball joint linkages mentioned but until now I’ve only ever dared use them for throttle links fearful as to whether they are strong enough for a rudder linkage.

As it was me that started the topic, I’d like to comment on the critique from Randy in respect of my home made linkage:

I agree that ideally there should be no bends in the linking rod(s). The bend seen in mine (near the rudder arm third photo) was tested and the internal longer straight rod (to the servo) bends first when a lot of pressure is applied (sufficient to move the rudder servo when armed). So the compromise is for me satisfactory.

The rod length in my set up is very easy to adjust, simply slacken off the two screws on the brass connector shown. Having found the optimum length, I trimmed off the protruding bits of rod but still have scope for a millimetre of adjustment either way if needed.

Even if you’ve got a one piece rod; With threaded connectors at each end for the chosen arm linkage, I would suggest that in fact it is a three piece set up due to the three sections that are joined and able to separate.

In respect of the 2mm set screw securing the two retaining collets (on the horns), these collets have minimal pressure applied to them in use and have worked faultlessly. However I take on board your concern and will check those more often to ensure that they are firmly in place.

Now, following a recent collision with my brother’s boat, I had to replace my damaged rudder assembly (it’s support bushings were hammered, the rudder was battered –linkage system not damaged at all):

The new rudder assembly came with this stainless steel linkage (for the CNC rudder arm). (Image below)

This is one of the better standard connections that I’ve seen supplied because it has a 3.5mm spigot that goes into the rudder arm and a 4mm set screw to secure the 2mm rod, with a stainless nylon locking nut to hold the linkage to the tiller arm.

I was tempted to use it but stuck with the devil that I know! As said it is all down to personal preference and if a system works well, perhaps it is best to stick with it.

I like the concept of the ball joint linkages mentioned but until now I’ve only ever dared use them for throttle links fearful as to whether they are strong enough for a rudder linkage.

As it was me that started the topic, I’d like to comment on the critique from Randy in respect of my home made linkage:

I agree that ideally there should be no bends in the linking rod(s). The bend seen in mine (near the rudder arm third photo) was tested and the internal longer straight rod (to the servo) bends first when a lot of pressure is applied (sufficient to move the rudder servo when armed). So the compromise is for me satisfactory.

The rod length in my set up is very easy to adjust, simply slacken off the two screws on the brass connector shown. Having found the optimum length, I trimmed off the protruding bits of rod but still have scope for a millimetre of adjustment either way if needed.

Even if you’ve got a one piece rod; With threaded connectors at each end for the chosen arm linkage, I would suggest that in fact it is a three piece set up due to the three sections that are joined and able to separate.

In respect of the 2mm set screw securing the two retaining collets (on the horns), these collets have minimal pressure applied to them in use and have worked faultlessly. However I take on board your concern and will check those more often to ensure that they are firmly in place.

Now, following a recent collision with my brother’s boat, I had to replace my damaged rudder assembly (it’s support bushings were hammered, the rudder was battered –linkage system not damaged at all):

The new rudder assembly came with this stainless steel linkage (for the CNC rudder arm). (Image below)

This is one of the better standard connections that I’ve seen supplied because it has a 3.5mm spigot that goes into the rudder arm and a 4mm set screw to secure the 2mm rod, with a stainless nylon locking nut to hold the linkage to the tiller arm.

I was tempted to use it but stuck with the devil that I know! As said it is all down to personal preference and if a system works well, perhaps it is best to stick with it.

Last edit: 14 years 7 months ago by Craig Dickson.

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Canadian Hot Rod RC Boats replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I use the ready made rods www.cc-racingengines.com/index...emart&Itemid=53

std 4/40 ends www.cc-racingengines.com/index...emart&Itemid=53

and seals from Dave at Prestwich (GA 19) www.prestwich.ndirect.co.uk/hdwraccs.htm

I don't have a need to pull linkages much so it works for me -- only takes a minute to unthread a end if rod if I need to - I like the positive feel - the nylock nuts on the 4/40 always seem to stay tight and I don't have issues with binding or ajustment.

I don't race though so to each their own - if it works for u

use it ....

std 4/40 ends www.cc-racingengines.com/index...emart&Itemid=53

and seals from Dave at Prestwich (GA 19) www.prestwich.ndirect.co.uk/hdwraccs.htm

I don't have a need to pull linkages much so it works for me -- only takes a minute to unthread a end if rod if I need to - I like the positive feel - the nylock nuts on the 4/40 always seem to stay tight and I don't have issues with binding or ajustment.

I don't race though so to each their own - if it works for u

use it ....

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

Canadian Hot Rod RC Boats replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I have used the little collars and locktite the set screw - but I also wrap a small piece of silicone hose over them to be sure the screw stays in.. If u cut a slice of good hose the same width of collar and slide over - screw stays in even if it loosens up.

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

marc replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I like this tip!

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Canadian Hot Rod RC Boats replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Last edit: 14 years 7 months ago by Canadian Hot Rod RC Boats.

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

tapkoote replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

canadian hot rod

thanks for that tip

I lost the set screw out of one of my throttle collars the last race

Tap

thanks for that tip

I lost the set screw out of one of my throttle collars the last race

Tap

Please Log in or Create an account to join the conversation.

- tapkoote

- Offline

- Posts: 83

- Karma: 1

- Thank you received: 1

Steve Seebold replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

The ones from from CC Racing engines look like the parts that Dubro sells at your local hobby shop.

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

bentoad replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

I make my own cheep and easy . I have a boat that does 100 yds in 2.8 seconds If it didn't break on that it should work most any where, I also use it on my model planses

Please Log in or Create an account to join the conversation.

- bentoad

- Offline

- 100 YARDS IN ---2.8 SECONDS

- Posts: 12

- Thank you received: 0

tapkoote replied the topic: Re: The perfect reliable rudder linkage? What do you find best?

bentoad

is that heat shrink tube?

tap

is that heat shrink tube?

tap

Last edit: 14 years 7 months ago by tapkoote. Reason: spelling

Please Log in or Create an account to join the conversation.

- tapkoote

- Offline

- Posts: 83

- Karma: 1

- Thank you received: 1

Time to create page: 0.178 seconds