Tech Article...

Some techniques and information to help you dial in that carburetor...

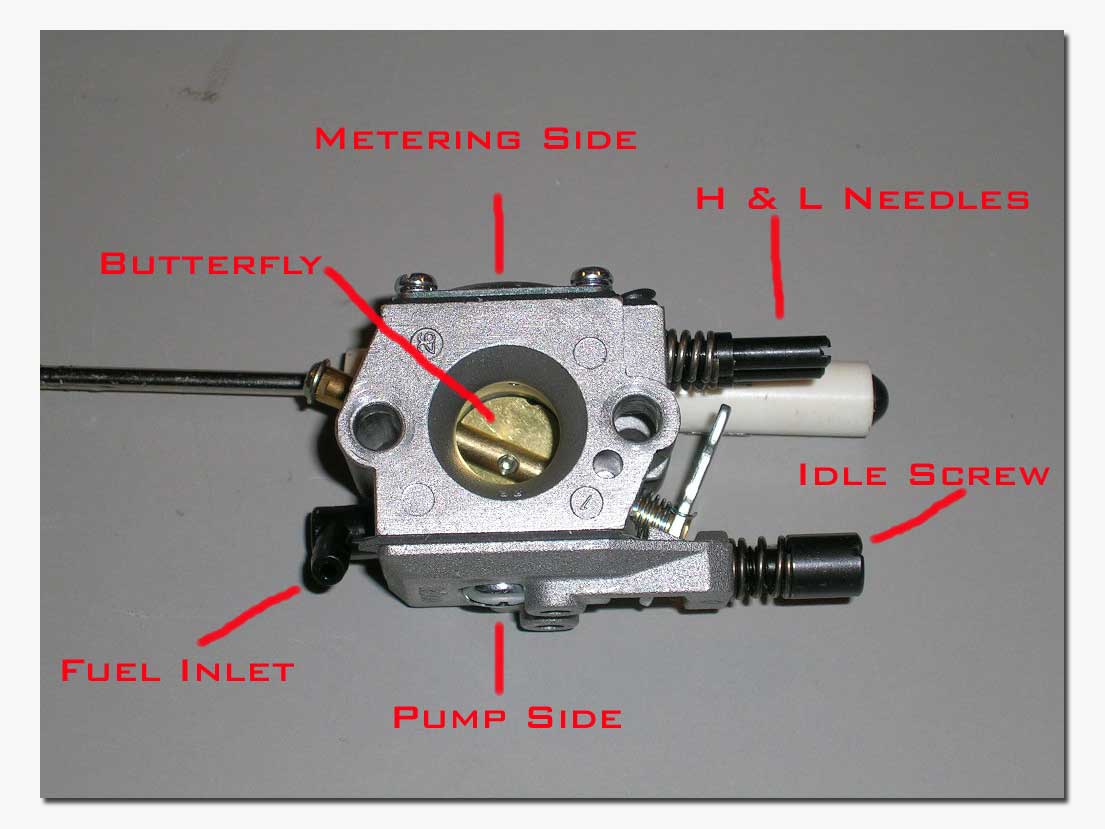

In this article we will discuss the different factors affecting the performance of the carburetors on our gasoline engines. By far the most used engines in gas boats are Zenoah engines or Zenoah based engines. Zenoah marine engines are supplied with Walbro brand carburetors that have both High Speed and Low Speed needles. This is the kind of engine and carburetor we will be referring to in this article and the tuning techniques presented. It is a fact however that these techniques would apply to many other types and brands of 2-stroke engines and carburetors.

We will assume that you are already familiar with how the Walbro carburetors work and what the low and high speed needles do and affect. If you haven't already read it, you should consider taking a few minutes to read our article on the Walbro carburetor here in Issue 15. It was intended to be a maintenance article, but I ended up including a lot of technical information on the design and operation of the Walbro carburetors.

Basic carburetor tuning...

First thing first! Find out the model of carburetor you have on your engine and use known baseline settings to start. Fine tune from there...

Low Speed: There are different techniques to tune the low speed needle. I don't use any fancy techniques. I use the manufacturer's setting and fine tune from there to get a good crisp low to mid speed transition when the boat is on it's stand. Ultimate fine tuning must be done by actually running the boat and noting throttle response from low to mid speed.

If you have no idea where to start with the low speed setting, you can try this technique. Make sure the High Speed needle is opened about 1.5 turns. Completely close the LS needle then open it 1.5 turns and start the engine (give it throttle if required to get it to start). If it won't run, try opening LS needle a bit more, continue until it will at least run. I don't think I have ever seen a Walbro carb on our motors that will require much less than 1 turn open on the Low needle to run. When you get the engine to idle, keep it at idle and slowly close the LS needle until the motor begins to "four stroke". You will know what this means when you hear it. It will actually begin to sound like a four stroke motor. From that point open the LS needle about 1/8 turn at a time until it idles ok again and transitions from low to mid without much hesitation.

High Speed: The high speed needle is, in my opinion, virtually impossible to properly tune without actually running the boat on water. When the engine is put under load (boat on water) it will lean out a bit. You can however start with known baseline settings and do a few quick "blips" of the throttle and adjust the carb so that it tends to "clean out" at full throttle and not bog or hesitate too much. The best advice here is to keep it rich rather than lean.

The final and optimal tuning is done by running the boat on the water and reading the spark plug. Start with a new sparkplug or use a wire brush to clean the electrode and ceramic insulator on your used sparkplug if you can't find a new one. Try to start with a slightly rich setting. Launch the boat and run it for a few full throttle laps and take the boat in. Remove the spark plug and inspect the electrode and insulator (the insulator is white when new). You are looking to get a tan coloured tip. If the tip is black or dark brown your high speed needle is too rich. Close it (Clockwise) 1/8 turn and run it a few more laps and check it again. If the tip of the spark plug is "grayish" color or white, the HS needle is too lean. Open it (CCW) and run it a few more laps before checking again. You might want to open it more than 1/8 turn to try and get on the rich side and tune down from there to be safe. Continue until the spark plug tip remains a nice tan color. This is a safe setting that will yield good performance. You can venture and run a bit leaner but remember that too lean a setting can quickly result into an engine rebuild job! The fuel in our boats also supplies the lubrication for the engines so leaning the fuel mixture also reduces the available lubricant to the engine.

Note: with the newer spark plugs and the better quality synthetic oils most of us now use, reading the spark plug can be a little difficult at times. It might be necessary to run the boat longer in order to get accurate readings...for this reason it is better to start with a rich setting and work your way down to avoid running the engine under lean conditions for extended periods.

Some factors that will affect the tuning of your carburetor:

Temperature: As ambient (air) temperature rises, the carburetor will need to be leaned. Some people might actually think the opposite to be true and lean out the carburetor in colder weather to keep engine hotter, and vice versa. This is false! Colder air is denser and thus contains more oxygen for a given volume. For this reason in colder weather you must make the mixture richer in order to balance the air-fuel mixture for optimum performance. If the ambient temperature rises in comparison to your last adjustments, the mixture should then be leaned to rebalance the air-fuel mixture as hotter air contains less oxygen per given volume.

Atmospheric Pressure: You can find out atmospheric pressure by using a barometer or the local weather stations will usually list the daily atmospheric pressures for given regions. The higher the atmospheric pressure, the more air (and thus oxygen) is getting inside your engine. When atmospheric pressure is higher, the carburetor mixture should be richer to maintain optimum air-fuel mixture. As the atmospheric pressure drops the mixture should be leaned accordingly.

Humidity: Humidity is the amount of moisture in the air. This moisture takes the place of oxygen in the air for a given volume. If the humidity level is higher, there is accordingly less oxygen in the air and the carburetor setting should be leaned accordingly to maintain proper air-fuel mixture. In dryer conditions, the mixture should be richer.

Altitude: This is a very important factor that can often be overlooked. If you purchase an engine from a builder in Florida and you live in Denver Colorado, the carburetor settings this builder suggests for his engines most likely will not be correct for you in your location (unless he has taken your altitude into consideration).

A general formula is that power in a 2-stroke engine will decrease by approximately 3 percent for every 1000 feet of elevation above sea level. Taking Denver Colorado (over 5000 ft elevation) as an example, the same engine would produce approximately 15% less power in Denver as opposed to if it were run at or near sea level, assuming it is properly tuned! Improperly tuned, it would be even worse!

As you increase in altitude, the atmospheric pressure drops and the mixtures must thus be set leaner accordingly to maintain the best possible air-fuel mixture. You will still have to live with the 15% decrease in power if you are in Denver, but you will experience much worse decreases in power if you don't tune to optimize with what is available in the air!

Here is a little table to summarize all that has been discussed above.

|

Weather Condition |

Needle Adjustments to Make |

|

Higher Air Temp |

Go Leaner |

|

Lower Air Temp |

Go Richer |

|

Higher Atmospheric Pressure |

Go Richer |

|

Lower Atmospheric Pressure |

Go Leaner |

|

Higher Humidity |

Go Leaner |

|

Lower Humidity |

Go Richer |

|

Higher Altitude |

Go Leaner |

|

Lower Altidude |

Go Richer |

Remember that more than one of these conditions can and probably will change at the same time. This will at least get you headed in the right direction with your tuning.

The best suggestion I can make is start with known base settings and tune from there following the guidelines above.

Happy Boating!