Product Review Article ...

Some "press in" Zero Drag Seals...instant "hop-up" for your Zenoah...

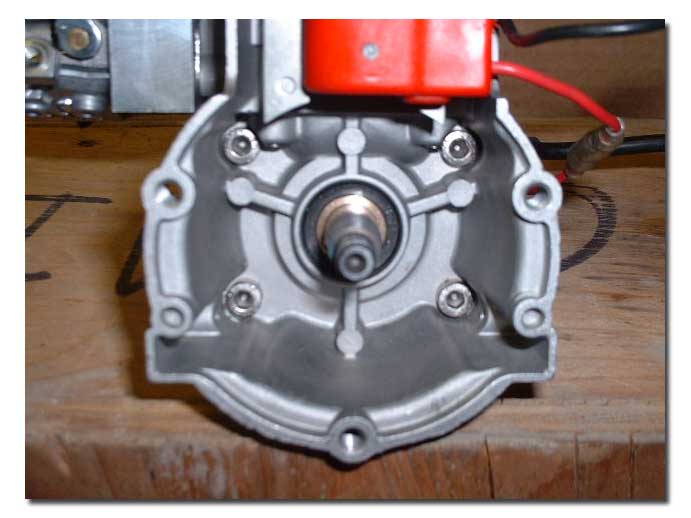

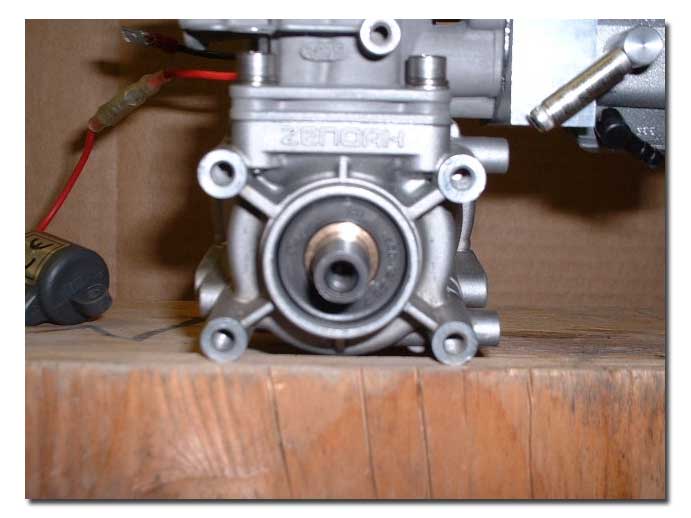

Looking for simple yet effective pop-in performance??? Well look no further. These Zero Drag Seals are exactly what you need to complement your modded Zenoah motor. Many of you either already have similar seals in your motors or have heard of them, but if you haven't, well let us tell you a little about them. They are availlable from several sources out there, but they are basically all the same design. CNC machined out of bronze bearing material, they are a direct fit into the existing factory seals in your Zenoah motor (260, 231, 230...) The simplicity of their design is amazing! Although I have not tried this myself, it would seem that you can actually install these seals without removing the crankshaft assembly from the motor. I installed mine while doing a rebuild on a motor, so I installed them into the factory seals, then reassembled the crank into the crank case halves. They are quite simple to install; you simply push them into the factory seals from the outside face of the rubber seal. In other words, hold the factory seal with its outside face towards you, and press in the seal tapered end first, into the rubber seal. The barb on the zero drag seal actually clips into the factory seal and holds it in place.

The seals are precision machined for a very close fit on the crankshaft, so there is one VERY important thing to check prior to using these seals: You must verify that the crankshaft is true. A max run out of .002" is recommended, less being better! We will try to cover this subject in a future article. If you don't have the tools to verify run out of the crankshaft, a well qualified motor builder or a machinist should be able to check this for you. Installing these seals in a motor with a crankshaft with too much run out will only cause problems with airleaks. I have experienced this myself. If the crankshaft is true and the seals are properly installed however, you can look forward to a slight increase in performance, notably a little extra top RPM. A very simple and cost effective modification for our little motors! Below are a few pictures of the seals installed in a motor.

I purchased my seals from Robert Finn, he can be contacted by Email at: This email address is being protected from spambots. You need JavaScript enabled to view it.

Like I said, there are several sources for similar seals, but I have only tried Robert's and I can vouch for their quality. The fit is perfect. The service and shipping was also excellent. The price paid was $17.95/pr + shipping. The last time I saw them for sale on www.jrcbd.com they were $16.45/pr including shipping in the USA. The price might have changed since then, I recommend contacting Robert for pricing information.

Happy motor modding!