Product Review Article...by Scott Schneider

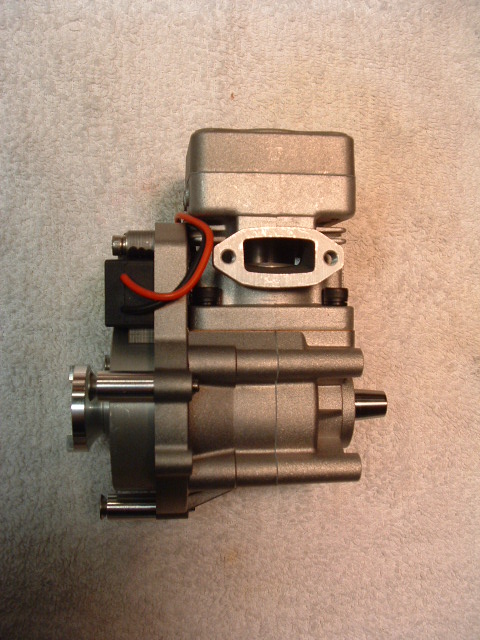

Our review of the all new RCMK S-254 side exhaust engine...

Welcome RC boating enthusiasts ... this Engine review should get your attention !

A name you may or may not have heard circulating within the RC boating community this past year or so is RCMK ...

which stands for, Radio Control Marine Korea.

This review is specific to their latest side exhaust 25.4cc engine, the S-254 which is a legal stock class engine under the IMPBA LS27 and NAMBA G-1 Gasoline engine rules.

This review is specific to their latest side exhaust 25.4cc engine, the S-254 which is a legal stock class engine under the IMPBA LS27 and NAMBA G-1 Gasoline engine rules.

First off let's say copying is the most sincere form of flattery, and the S-254 delivers!

Based off of the battle tested Zenoah G260PUM series engine, RCMK has taken the basic platform and given it a major beef up with some really well executed refinements.

Looking from the cases up into the top end and beyond, here is a list of refinements and specifics .....

The Crankshaft: has been beefed up on the magneto side by keeping it a constant diameter from the bearings all the way out to the flywheel taper. The radius at the corner of shafts at counterweights is smaller allowing the use of standard high speed C-3 fit 6001 bearings. (Zenoahs require a special OEM bearing). The PTO end retains the familiar taper and uses the same drive collets.

** Note: Collets like the aeromarine will need to be shortened slightly because of interference with the outboard crank bearing. It needs to be approximately 1/16" shorter in most cases. * RCMK has there own AM style collet set that works great !

Looking from the cases up into the top end and beyond, here is a list of refinements and specifics .....

The Crankshaft: has been beefed up on the magneto side by keeping it a constant diameter from the bearings all the way out to the flywheel taper. The radius at the corner of shafts at counterweights is smaller allowing the use of standard high speed C-3 fit 6001 bearings. (Zenoahs require a special OEM bearing). The PTO end retains the familiar taper and uses the same drive collets.

** Note: Collets like the aeromarine will need to be shortened slightly because of interference with the outboard crank bearing. It needs to be approximately 1/16" shorter in most cases. * RCMK has there own AM style collet set that works great !

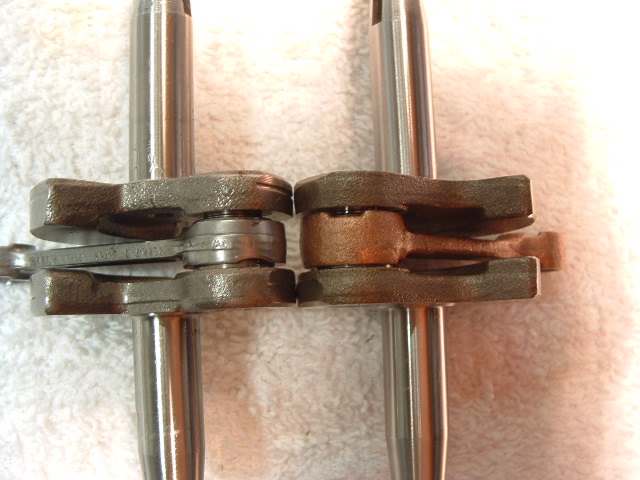

The connecting rod is beefed up with a tad with more material within the rod itself with increases in bearing width at both ends . * Big End of rod is .090" wider having more surface area with a wider bearing to match.

The small end of the rod gets the same treatment being .040" wider with a matching bearing. (Very Nice improvement!)

Crankshaft stroke is 28mm.

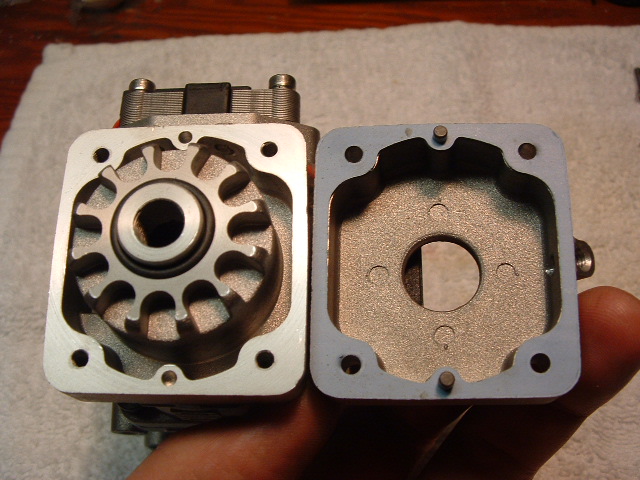

The Crankcase: has really been beefed up starting with a much thicker casting throughout. (The S-254 uses a CAST case and not billet as other versions use) The material cast around the bearings is heavier, as is the transfer passage area above the bearings. The best part is the use of four crankshaft bearings! Yes, two bearings per side that really do an excellent job of adding extra support to the crank/bottom end assembly. (This should really reduce the chance of the crank twisting when ingesting a gulp of water ... though it is best avoided all together.)

The bearings are set up in a configuration with the inboard ones being open-unshielded bearings, and the outboard ones being double-sealed units acting as the primary crank case seals.

The bearings are set up in a configuration with the inboard ones being open-unshielded bearings, and the outboard ones being double-sealed units acting as the primary crank case seals.

Both case halves have machined gasket surfaces indexed together with three (3) steel alignment pins.

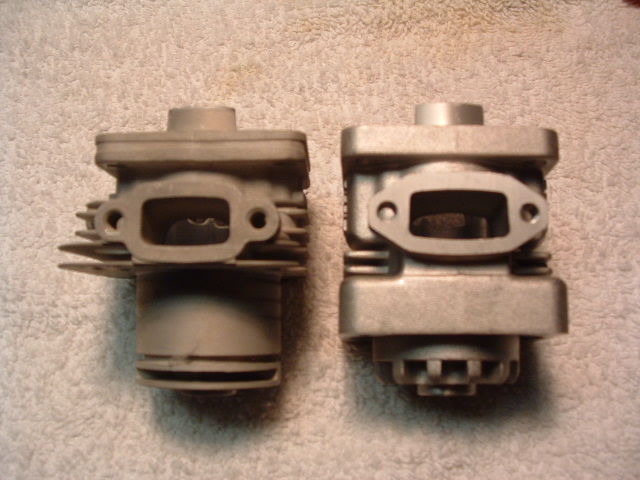

The Cylinder & Piston: also have a major application of beef it up! A very good quality thick cylinder casting that incorporates the water jacket gets capped by a cast cover indexed on 2 pins retained by four stainless steel screws.

The transfer ports resemble the typical 4 port layout but they are reshaped and re-contoured. Exhaust and Intake ports are a lot larger offering much greater flow potential. Cylinders chromed bore is just beautiful, having a very smooth finish with quite uniform plating throughout.

The Piston is another place RCMK addressed issues in design. Rather than beefing it up, they trimmed it down! Casting it very light with no extra material below the one ring, thin skirt and dome area have reduced the mass and weight.

The transfer ports resemble the typical 4 port layout but they are reshaped and re-contoured. Exhaust and Intake ports are a lot larger offering much greater flow potential. Cylinders chromed bore is just beautiful, having a very smooth finish with quite uniform plating throughout.

The Piston is another place RCMK addressed issues in design. Rather than beefing it up, they trimmed it down! Casting it very light with no extra material below the one ring, thin skirt and dome area have reduced the mass and weight.

The wrist pin hole is machined blind on one side only requiring one (1) circlip for pin retention.

Best of all the piston is taper-ground making it smaller in diameter at the dome/ring end and larger at the bottom of the skirt. The taper is approximately .003" total. No more stuck or cold seized piston issues here! ... Very NICE touch.

The piston has also been machined to have two vent holes feeding air/fuel through the piston into the intake side transfers.

The piston has also been machined to have two vent holes feeding air/fuel through the piston into the intake side transfers.

*This allows better case scavenging and a cooler operating piston with better lubrication of the piston pin bearing.

Cylinder bore is 34mm.

Note: Pictures below are Zenoah on the left, RCMK on the right.

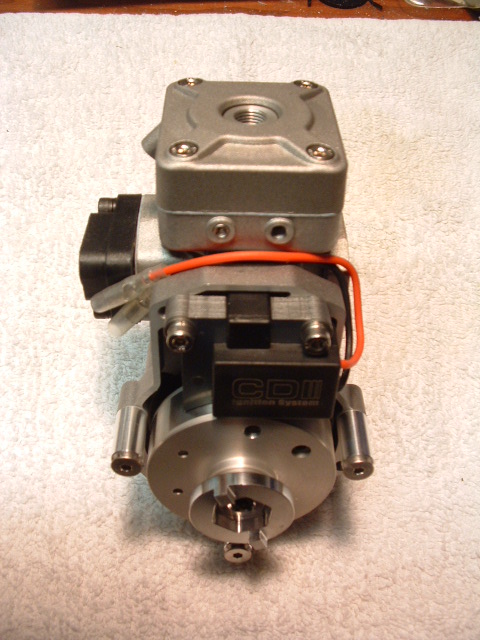

The Ignition System: looks to be identical to the Zenoah system, though it does differ in color and in small cosmetic changes.

The flywheel is machined on all surfaces making it very true running and well balanced. The starter dog is billet and nicely designed. The secondary coil mounts above the starter on a supplied mount. (No case mounting lugs provided).

The primary generator/trigger coil that screws to the crankcase is supplied with two pair of mounting holes on the crankcase.

One set places the coil at the 12:00 position being "stock" timing, and the factory's delivered setting. The other set of holes move the coil into a more advanced position that appears to be approximately 4 degrees more advance. (If following Zenoah specs that would be approximately 30 degrees BTDC at 9000 rpm in the stock position and +4 advanced).

The Rest: Intake manifold is a nicely cast resin unit that matches the carburetor's throttle bore and the cylinder quite well.

The carburetor looks like the typical WT257, but differs internally and in needle settings. The throttle bore is .625" with a .500" venturi. The rope starter assembly seems to be identical to the Zenoah's. The spark plug provided is an NGK brand.

Performance:

Testing on the water was fairly limited, but enough to test how much power it had relative to the stock Zenoah G260PUM of which it is designed from.

The RCMK S-254 showed itself as the stronger engine. Performance gains were greater RPM with a tad more torque.

Note: These engines as delivered do not have a starter plate supplied (very few would use them anyways) and therefor have the starter and screws in the box. ( When attaching starter side mount, make sure starter operates smoothly )

* The mounting screws passing threw the spacers should just be flush coming threw the case boss's, add a washer or two if needed ) * Very thin motor mounts may need a washer, thick mounts should be fine.

* The mounting screws passing threw the spacers should just be flush coming threw the case boss's, add a washer or two if needed ) * Very thin motor mounts may need a washer, thick mounts should be fine.

Where the real bang is going to happen is once modifiers tweak on it taking advantage of the extra thick castings and beefed-up crank/bearings/case. * Early results on running two modified S-254's show this potential well....Wow!

As an out of the box stock engine, one nice and solidly built unit. We give it a BIG two thumbs up rating.

Factory specs:

(Taken from an on-line listing by "Tough Racing")

Power: 5.2Hp @ 16,000 rpm (Piped)

Timing: 30* BTDC @ 7000 rpm

Compression ratio: 10:1

Carburetor: Walbro WT-929

** Stay tuned for our next chapter on the RCMK engines having the Rear Exhaust R-254 version under the eyes of the MGB technical staff . Also a "How-to" dealing with high performance porting of the S-254 engine.

Regards,

Scott Schneider

MGB Technical Advisor.

Regards,

Scott Schneider

MGB Technical Advisor.

Contact Information

GIZMOMOTORS (Exlclusive US Distributor of RCMK Products)

| 550 Grove Dr. |

| Bartow, Florida |

| Phone: 863-533-6060 |

| 33830 USA |

| |

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Website: www.gizmomotors.com