How-to Article ...by Denzil Sheckler

An informative article on how to modify a boat propeller...

Click here for the German translation of this article!

Klicken Sie hier fr die deutsche bersetzung dieses Artikels!

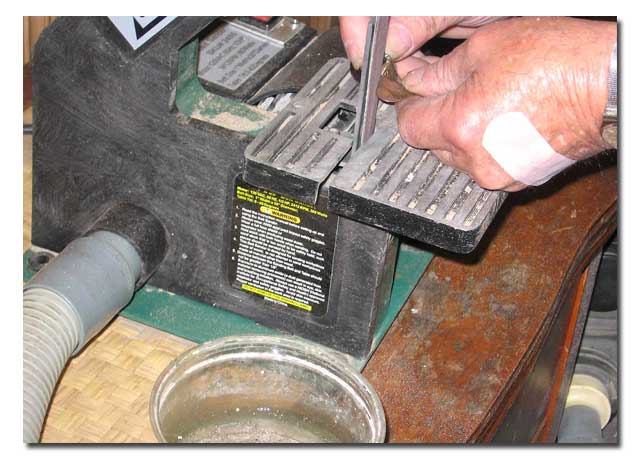

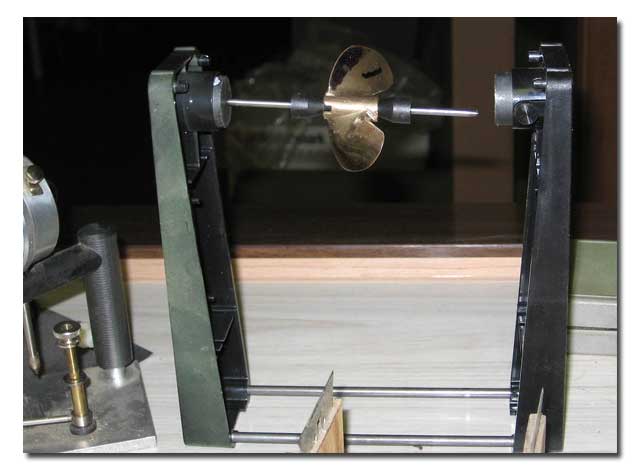

The ABC H-31 prop is a 70 mm diameter prop with about a 4.6 pitch. I am going to modify it for a Whiplash hydro. First step is to cut back the tongues. I mark up the tongue area with a felt marking pen and scribe the shape that I want from a cardboard template. I then trim the tongue back on a 1” belt sander. Mount the prop on a ¼” arbor with two drive collars. Hold the arbor in a hobby vise to backcut the blades with a 1/8” diameter carbide burr 1/8” deep at the root of the trailing edge of each blade. I then backcut the blades of the prop so there is 1/8” at the root and 0” at the tip removed. This is done on the belt sander so there is a sharp square edge on the concave side of the blade. The next step is to thin the blades and sharpen the leading edge on the belt sander. I have marked the concave sides of the blades #1 & #2 with a felt marker for identification purposes. When the blades are sharp and thin I start checking the balance. When the prop is balanced it is now time to finish the blades surface which I do with a little bit of filing if necessary and recheck balance.

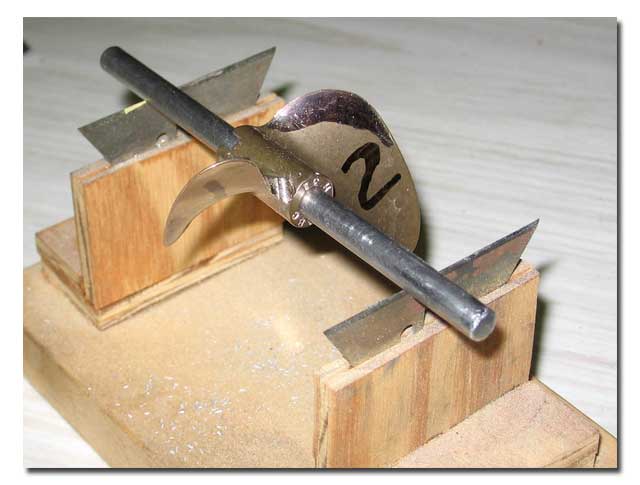

Finish with wet sanding, starting with 120 grit, followed by 600 grit and finished with 1500. I use a 1/8” x 5/8” stick wrapped with the paper to do this finishing and it is easy and quick. To re-pitch the prop use some 1500 paper doubled up in the hobby vise and grip the trailing edge of the blade. Insert a ¼” shaft in the bore of the prop and torque bend the blade. Check the pitch on the Rossi Pitch Gage and re-do until correct. In this case I wanted a 5.9 pitch on the last 20 degrees. A little spooning is necessary, as I do not think the H-31 had enough. The spooning increases the prop efficiency. I do this with a plastic hammer and a 1” diameter steel ball in the hobby vise. Only about a 1/32” is enough. Since most boats run surface drive and only the one blade is in the water at a time, any water that slides off the end of the blade lifts the stern of the hull creating lift. I would like to add that the 1/8 “ backcut reduces lift and is not necessarily desirable on some boats.

*** Please note that most propellers on the market today use a beryllium copper alloy. Absorption of this substance in the body can cause serious long term health problems. Please make sure you wear adequate protection equipment when working with beryllium copper props. Safety glasses, respiratory masks and gloves are a minimum. Also you should work in a well ventilated area and wash up thoroughly when finished. Avoid transporting dust and filings to other areas of your home or workplace. For more information on beryllium visit THIS SITE.