How-to Article...By Frank E. Mintz

Thinking of using a trimmer engine for your next boat project??? Read these tips and suggestions first and save yourself some headaches!

If you want to get into a gasoline powered boat but your modeling budget doesn't have room for a $500 motor, take heart. You can convert a gas string trimmer to model boat power with little effort. The process is not new. Hobbyists have been producing gasoline powered boats with trimmer size motors for 25 years. However, if you don't know what's involved you can be frustrated at every turn. I will try to provide a primer for the conversion process and some lessons that I have learned along the way that will help you reduce the frustration factor.

Choosing a Trimmer Conversion Subject

There are lots of power equipment possibilities. Most of them can be made to work in a boat. There are some motors that will require lots of accommodations and they will extend the frustration train. Choosing the right conversion subject will limit the frustration and the project will have a much better probably of success.

You can get trimmers from lots of places. Buy one new, use one you already have, haunt the yard sales or, if you want a selection at a great price, go to your local small engine repair shop. They almost always have trimmers that have been abandoned or scrapped with them and most of the time the power head is useable. In any case, be careful to select one that has all the positive attributes described here and in OK condition. By that, I mean it has good compression when pulled with the cord and it has all the required parts to run. Make sure it will generate spark too. This malady is often the demise of a power head and sometimes too expensive to correct. If you are shopping in a repair shop "bone yard" you can buy two and get all the parts to make one complete working unit. Be sure you get two of the exact same model. Don't buy one that will not turn over as your main subject. The other most common death is caused by running without proper oil/gas mix which causes the engine to seize. The subject used in this article was purchased for $15 from a local small engine repair shop. You can find subjects on eBay as well, but you need to know what model you want first. Try to get a complete trimmer. We can use the flex cable, aluminum shaft, carburetor control cable, kill switch, gas tank and some of the motor shroud in the conversion. In selecting a trimmer, let's look at some specifics about the configuration of the power head that needs to be addressed for use in a boat.

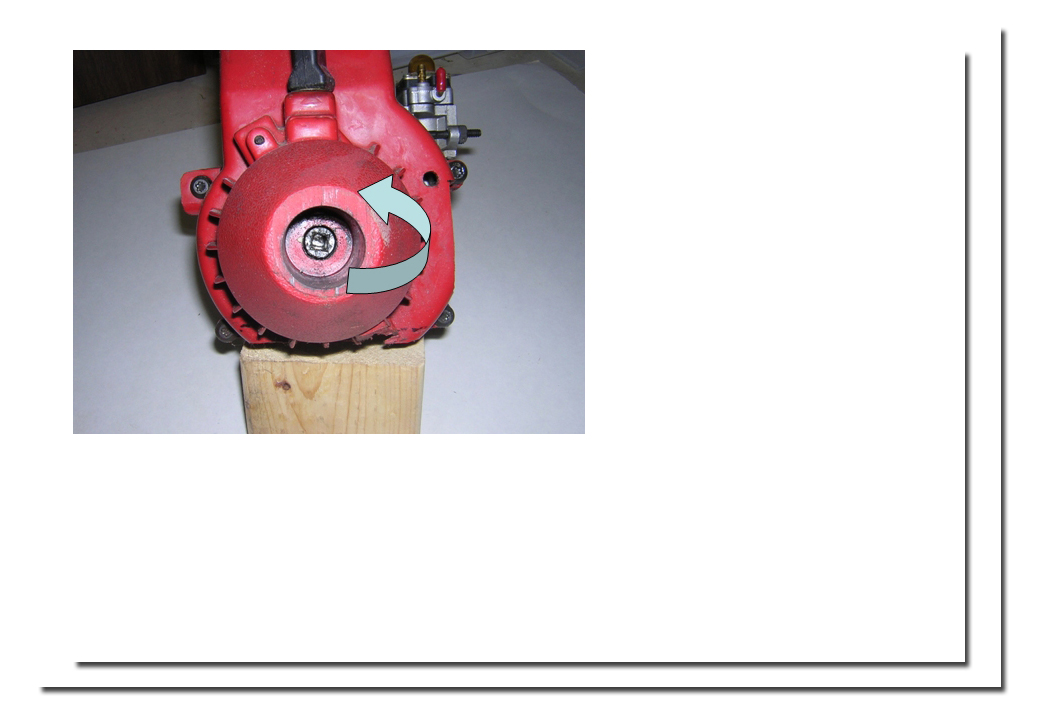

1 - Make sure that the engine turns in the proper direction. When you look at the stern of a model boat the propeller turns counter-clockwise. Make sure that your subject motor runs counter-clockwise when you look at the drive shaft end. Most trimmers turn in the correct direction which is one reason for their popularity. Most chain saws do not, so be careful when considering a chain saw as your conversion subject. Chain saws also have no stock connection to a flex cable or "U" joint, so stay away from them if possible. Most leaf blowers and other small power equipment turn correctly but make sure before going much farther. They also have drive connection problems that need to be over come for boat use so try to stick to a trimmer if you can.

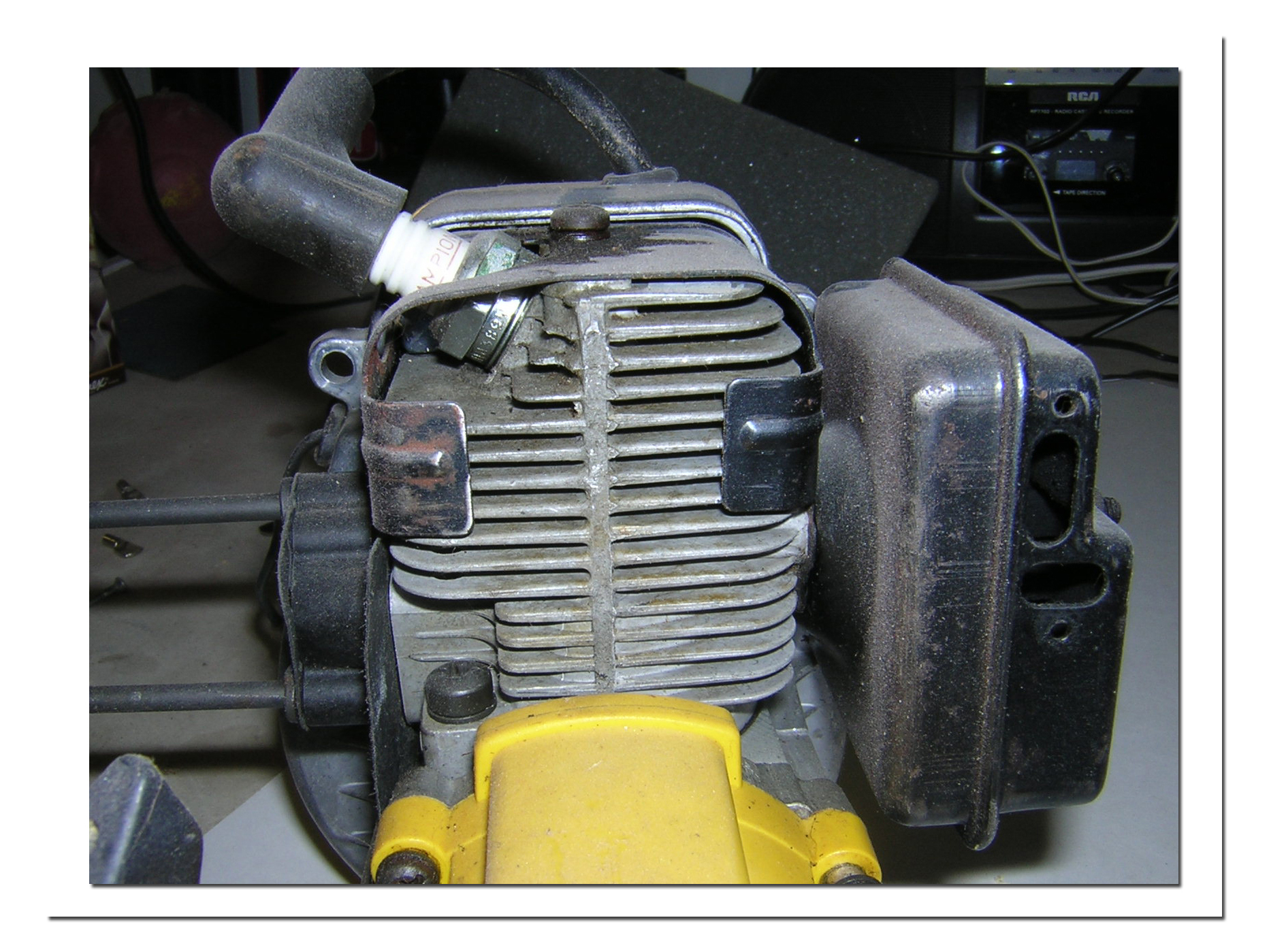

> Pic of Carb location<

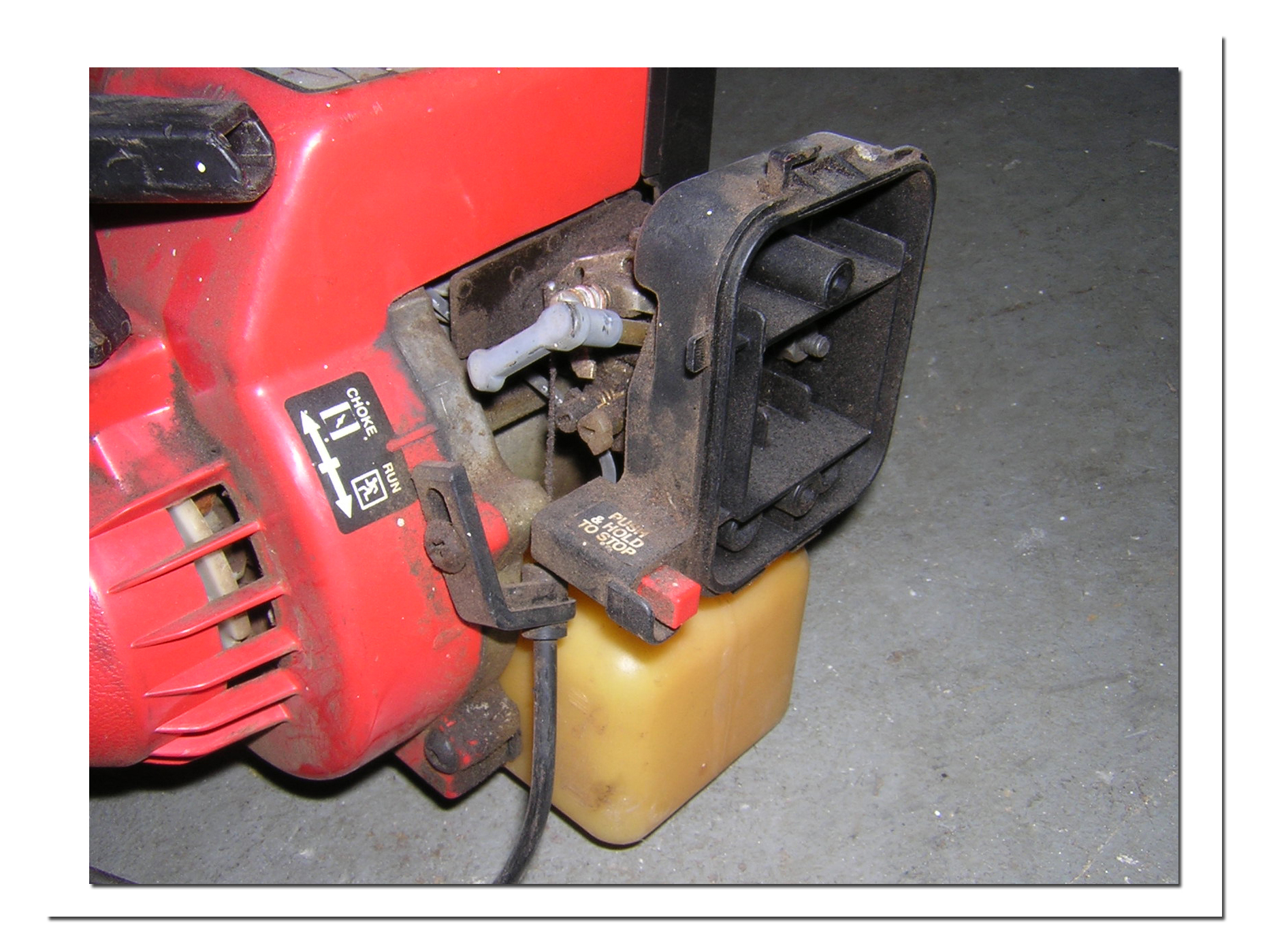

2 - Where is the carburetor mounted on the motor? If it is mounted on the cylinder and perpendicular to the crankshaft, great! If the carburetor is mounted to the base opposite the cylinder or on the rear you will have "issues" mounting the motor in the boat. The throttle control connection will also be a problem so try to stay away from this configuration. Typically the Ryobi and Craftsman brands have these "issues". Brands using the Homelite, McCulloch, Echo (Kiortz) or Komatsu Zenoah base engine generally are good choices.

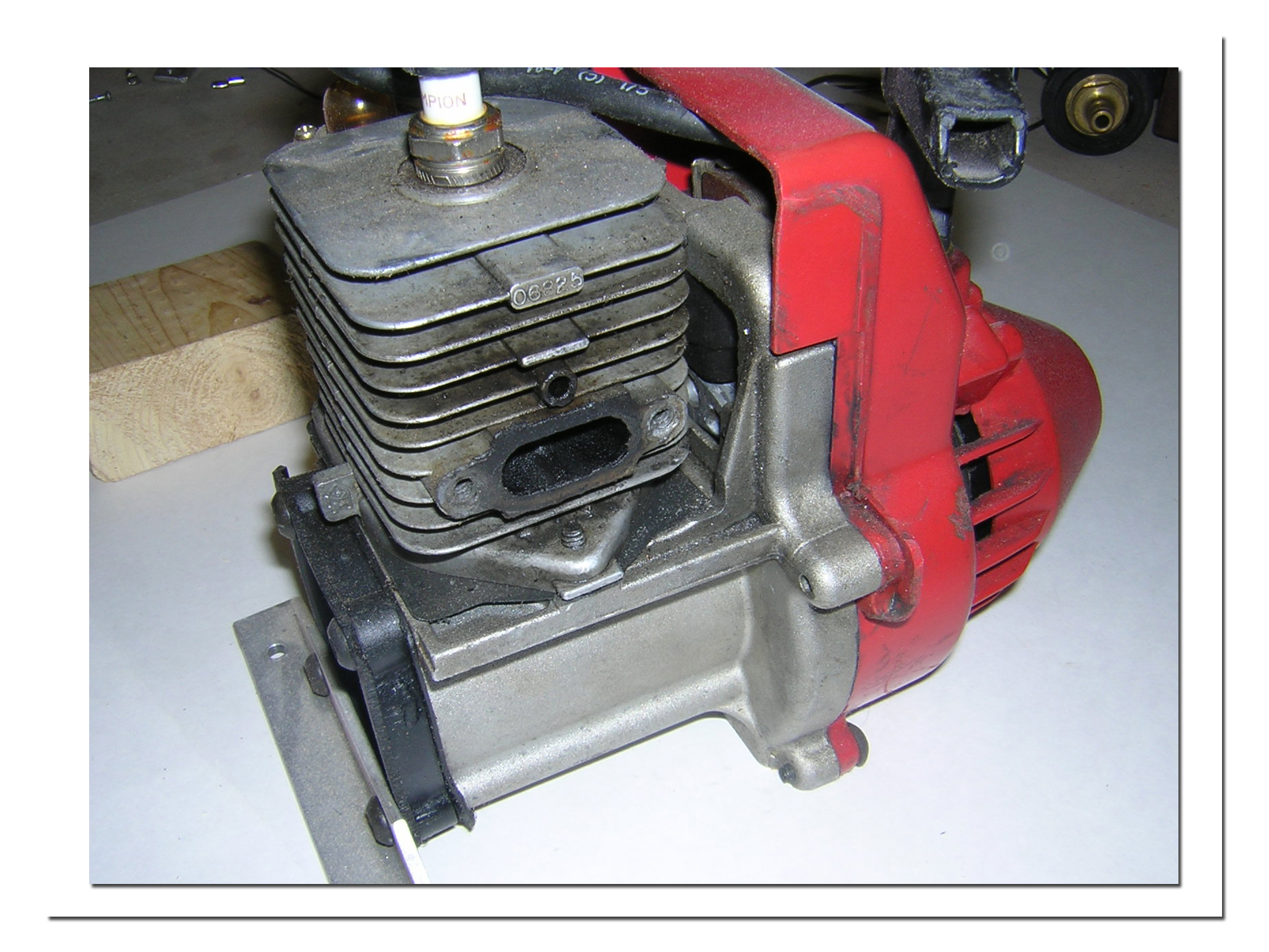

3 - Where is the exhaust on the motor? I am not talking about the muffler exit. I am referring to the exhaust on the cylinder. If it's direction is at right angle to the shaft, that's great. If it's to the rear (directly away from the trimmer shaft, Ryobi style) it may be a problem. Most muffler exits are away from the shaft of the trimmer (even on the side exhaust versions) which will be the wrong direction for mounting in a boat. On rare occasions you can turn the muffler 180 degrees and remount it but most of the time the muffler will not fit oriented this way. I will address simple muffler modifications that may be needed later.

4 - Where is the start cord? Most start cords will be between the cylinder and the trimmer shaft. Make sure that it pulls up in the direction of the cylinder toward the sparkplug. If it pulls away from the sparkplug, it's a big problem. If the start cord is on the rear of the trimmer, that's usually good. It also needs to pull in the direction of the sparkplug. Some of the rear mounted start cords can be rotated and repositioned to accomplish this. Be careful here, however. Older McCulloch trimmers used heavy metal fronts with an integral clutch and the engine will be much heavier than you want it to be. Good manufacturer choices with rear start cords are Echo (Kiortz), Red Max (Komatsu Zenoah), Toro and Stihl.

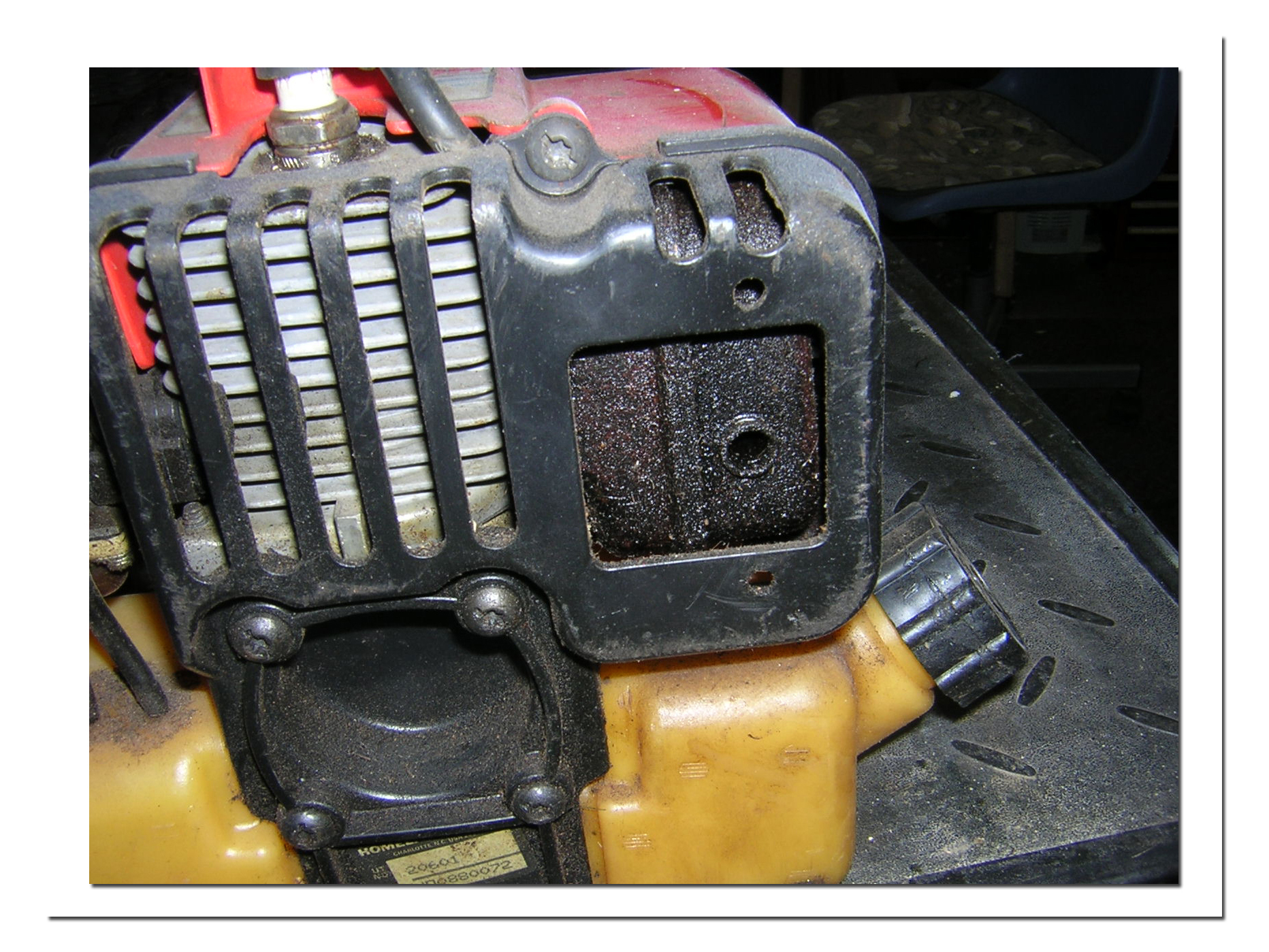

5 - Does the trimmer have a clutch? This is not a show stopper either way but it will affect the boat operation and needed accessories to the motor. To test for a clutch, remove the plug wire from the spark plug, and pull the start cord while holding the string head. If the start cord moves and the string head does not, it has a clutch. If you want or need the boat to stand still with the motor running, a clutch is necessary. Most of the time a clutch is not necessary because the boat can be launched running and shut-down from the radio on the retrieve. The stock clutch will work just fine for a boat with a stock trimmer motor. If you have a clutch and you add a water cooled cylinder, you should also add a water pump to the system. Walbro makes pumps activated by the base compression/vacuum through tubing and a nipple added to the engines case. Unless you really want or need water cooling, this complication is why I suggest staying with the original air cooling on a sport boat.

6 - Spark plug location? This is only a concern if you intend to convert the engine to water cooling. Engines with the plug in the center of the cylinder and in line with the piston movement are easier to convert. Plugs that are at an angle with the cylinder create problems with the modification for the water jacket and, unless you have machining equipment available, are difficult to convert to water cooling.

If you follow the suggested trimmer attributes I have laid out here your conversion to a model boat will be much easier and a fun project. I have made trimmer conversions for many boats and the lessons I learned along the way are shared here. You will have your own "issues" but working through them is part of the fun and satisfaction of doing it yourself.