|

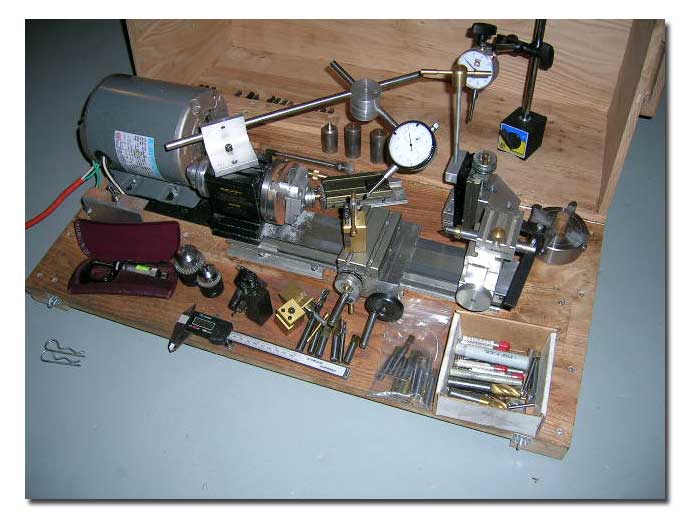

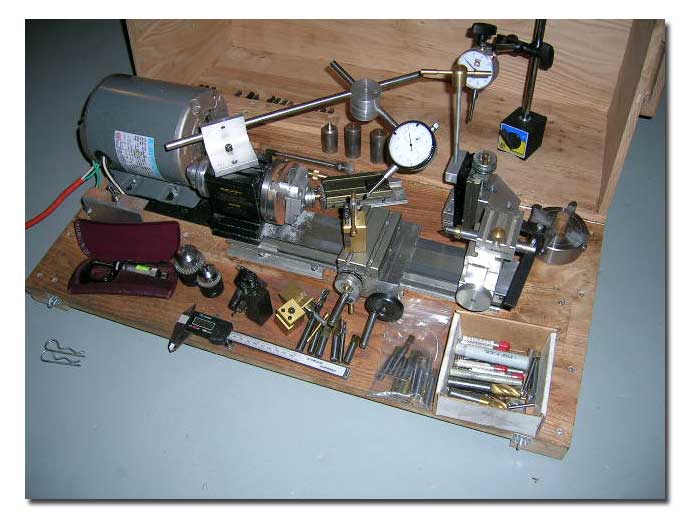

Well, to start off this new segment of the magazine, I thought it might be appropriate to show the readers what I myself use for my hobby machining needs. It’s not much as far as size goes, but it has served its purpose for a few years now. Here are a few pictures of my Taig lathe, with all the accessories and tooling I have for it. The stock lathe is just big enough to allow you to turn a Zenoah cylinder for facing, and using a milling attachment, you can machine the ports, including transfers, intake and exhaust. You must be a little creative when using such small machines though, so be prepared for a lot of trial and error! The precision of the Taig lathe is fairly impressive if setup correctly and well maintained. I use mine for modifying motors sometimes, but mostly for machining my own hardware for my boats. Keep in mind though that for milling large pieces such as rudder blades, this machine is not adequate. Because of its limited travel using the milling attachment, you must move the work piece in the vise several times, and the vise just isn’t accurate enough to make nice even surfaces if you re-clamp. If you are going to mill with this machine, you must be able to do a complete face without repositioning on the vise. You can increase the travel, by moving the vise itself on the cross-slide, this is pretty accurate, but that’s about as good as it gets. As far as turning and milling small pieces though, it is a great little machine for the price in my opinion. One important thing to keep in mind is that the Taig does NOT have threading capabilities.

In future issues, I will try to put together some articles to give readers an idea of what can be done and expected from this type of equipment. We will also have some interesting machining articles contributed from This email address is being protected from spambots. You need JavaScript enabled to view it. from Germany. Andre does some superb work that is well worth displaying in this segment.

Some specs on the Taig Lathe: (info from www.taigtools.com)

GENERAL

|