how to do the driveshaft?

bshey created the topic: how to do the driveshaft?

I am building and rc gas boat with a 32cc ryobi engine and clutch. What shaft should I use and how should I connect it? Also, What prop should i use? thanks for the help.

Please Log in or Create an account to join the conversation.

- bshey

- Offline

- Posts: 27

- Thank you received: 0

Superchomper2003 replied the topic: Re: how to do the driveshaft?

Hi,

I don't know what adaptor you will need or if they even make one. You may have to make one. I talked to they guy over at www.whobbies.com and he was a great help and got my fixed up with everything I needed. Call them up and he should be able to tell you what you need.

I don't know what adaptor you will need or if they even make one. You may have to make one. I talked to they guy over at www.whobbies.com and he was a great help and got my fixed up with everything I needed. Call them up and he should be able to tell you what you need.

Please Log in or Create an account to join the conversation.

- Superchomper2003

- Offline

- Posts: 14

- Thank you received: 0

kartrobison replied the topic: Re: how to do the driveshaft?

If you can send me a picture of the motor I can take a look I have used two weedy motors in my boats

also I used the smallest prop that www.zippkits.com sells it was cheap and seemed to work but I think I could also use the next size bigger and that would work to.

This email address is being protected from spambots. You need JavaScript enabled to view it.

also I used the smallest prop that www.zippkits.com sells it was cheap and seemed to work but I think I could also use the next size bigger and that would work to.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Last edit: 14 years 11 months ago by kartrobison. Reason: typo

Please Log in or Create an account to join the conversation.

- kartrobison

- Offline

- Posts: 6

- Thank you received: 0

Ozpulse replied the topic: Re: how to do the driveshaft?

If you are running the complete engine assy, the clutch should have the square drive for the flex cable already.

Once you find the COG and install the engine, the square end of the flex cable will slide into the clutch assy. You just have to cut the cable then to the right length to glue/solder into the ferrul/sleeve on the drive shaft that passes throught the strut assy. Just get everything else done first ie. engine, stuffing tube, strut assy.

Once you find the COG and install the engine, the square end of the flex cable will slide into the clutch assy. You just have to cut the cable then to the right length to glue/solder into the ferrul/sleeve on the drive shaft that passes throught the strut assy. Just get everything else done first ie. engine, stuffing tube, strut assy.

Awwwww! Your little engine is sooooo cute!

Please Log in or Create an account to join the conversation.

- Ozpulse

- Offline

- Posts: 532

- Karma: 4

- Thank you received: 0

bshey replied the topic: Re: how to do the driveshaft?

Great thanks for all the help but i still have some questions. First of all, what is a COG? I am afraid I can't send pictures of the engine because I have not seen it yet, I am buying it from someone online who is preparing it for me but has not yet shipped it. All I know is that the lower end of the engine includes a clutch and the whole assembly is from the 90's. I would like to start ordering the hardware and zippkits looks like it has everything. Could you please give me the item # of the parts you mentioned earlier? Here is what the person I am buying the engine from said when I asked him about the driveshaft:

This is a square drive I'm sure it's the standard 1/4. I can send a stub flex shaft from a convertible trimmer It is male on one end and female on the other. You can cut it to how long you need. You can stuff the cut ends of the flex shaft in a piece of pipe and weld it to the flex shaft pieces to make a custom drive shaft. If you make the shaft too long you may need a pillow block bearing mid way It would be easy to mount one to the piece of pipe shaft coupler if you need a long shaft.

What does he mean by the flex shaft and what does he mean by pillow block bearing? Thanks for all the help.

This is a square drive I'm sure it's the standard 1/4. I can send a stub flex shaft from a convertible trimmer It is male on one end and female on the other. You can cut it to how long you need. You can stuff the cut ends of the flex shaft in a piece of pipe and weld it to the flex shaft pieces to make a custom drive shaft. If you make the shaft too long you may need a pillow block bearing mid way It would be easy to mount one to the piece of pipe shaft coupler if you need a long shaft.

What does he mean by the flex shaft and what does he mean by pillow block bearing? Thanks for all the help.

Please Log in or Create an account to join the conversation.

- bshey

- Offline

- Posts: 27

- Thank you received: 0

Ozpulse replied the topic: Re: how to do the driveshaft?

No worries mate!

By flex shaft he would be refering to the flex cable, I remove this from the snippers that I convert. Basically its a spring steel cable pressed square at each end which passes down the centre of the snipper shaft/tube and transfers the drive from the motor to the snipper head.

Im guessing by pillow block bearing he is meaning a support bearing around the middle of the shaft?

Normally you wont need one of these as the brass stuffing tube we use for the flex cable to pass through will only allow for minimal movement. Although you will need to support the stuffing tube in the hull to stop movement a possible failure.

You might want to double check with him as his description is puzzling.

COG is the point of balance(front to rear) most hulls will be set anywhere from 28 to 32 percent of the hull length from the transom(rear) depending on hull design and engine power. Improperly set this will result in a boat that will not get up on a plane(too far foreward) pushing the nose down or if too far back flipping the boat at higher speeds. COG is usually set once you have all the radio gear and hardware on the boat, the last thing I do is mount the motor as this is the heaviest part and can then be positioned to obtain the proper balance. Once mounted you will then be able to measure up the flex cable and cut it to the correct length for your drive and install the stuffing tube etc.

I will see if I can get some pics for you as it much easier to get the idea that way.

By flex shaft he would be refering to the flex cable, I remove this from the snippers that I convert. Basically its a spring steel cable pressed square at each end which passes down the centre of the snipper shaft/tube and transfers the drive from the motor to the snipper head.

Im guessing by pillow block bearing he is meaning a support bearing around the middle of the shaft?

Normally you wont need one of these as the brass stuffing tube we use for the flex cable to pass through will only allow for minimal movement. Although you will need to support the stuffing tube in the hull to stop movement a possible failure.

You might want to double check with him as his description is puzzling.

COG is the point of balance(front to rear) most hulls will be set anywhere from 28 to 32 percent of the hull length from the transom(rear) depending on hull design and engine power. Improperly set this will result in a boat that will not get up on a plane(too far foreward) pushing the nose down or if too far back flipping the boat at higher speeds. COG is usually set once you have all the radio gear and hardware on the boat, the last thing I do is mount the motor as this is the heaviest part and can then be positioned to obtain the proper balance. Once mounted you will then be able to measure up the flex cable and cut it to the correct length for your drive and install the stuffing tube etc.

I will see if I can get some pics for you as it much easier to get the idea that way.

Awwwww! Your little engine is sooooo cute!

Please Log in or Create an account to join the conversation.

- Ozpulse

- Offline

- Posts: 532

- Karma: 4

- Thank you received: 0

bshey replied the topic: Re: how to do the driveshaft?

Well that definitely clears things up. Thanks. Do I need to purchase a flex shaft based on what my seller said? I believe that he says something about sending along a flex shaft?

Also, does the flex shaft only need to pass through a stuffing tube when it goes through the hull? Is it open and free from the time it exits the bottom of the hull until it enters the transom? Do drive dogs fit onto the end of a square shaft and do you then need to solder the prop on? Sorry for all of the question I am new to rc boating.

Also, does the flex shaft only need to pass through a stuffing tube when it goes through the hull? Is it open and free from the time it exits the bottom of the hull until it enters the transom? Do drive dogs fit onto the end of a square shaft and do you then need to solder the prop on? Sorry for all of the question I am new to rc boating.

Please Log in or Create an account to join the conversation.

- bshey

- Offline

- Posts: 27

- Thank you received: 0

kartrobison replied the topic: Re: how to do the driveshaft?

here is a way that works

use brass tube then cut your 1/4 flex cable then use a brass ferrule to attach the cable to the 1/4 stubb shaft and solder the other end to the cable, then buy the drive dog and prop. oh ya and a brass bushing for the shaft to ride in

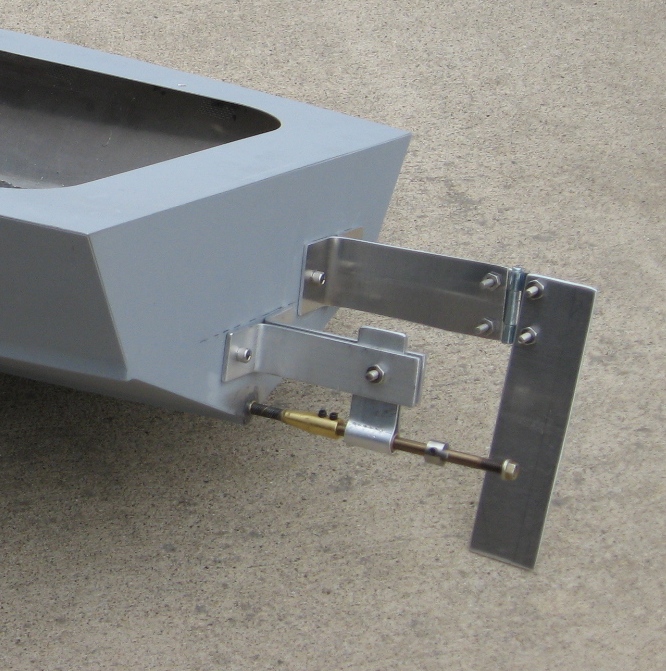

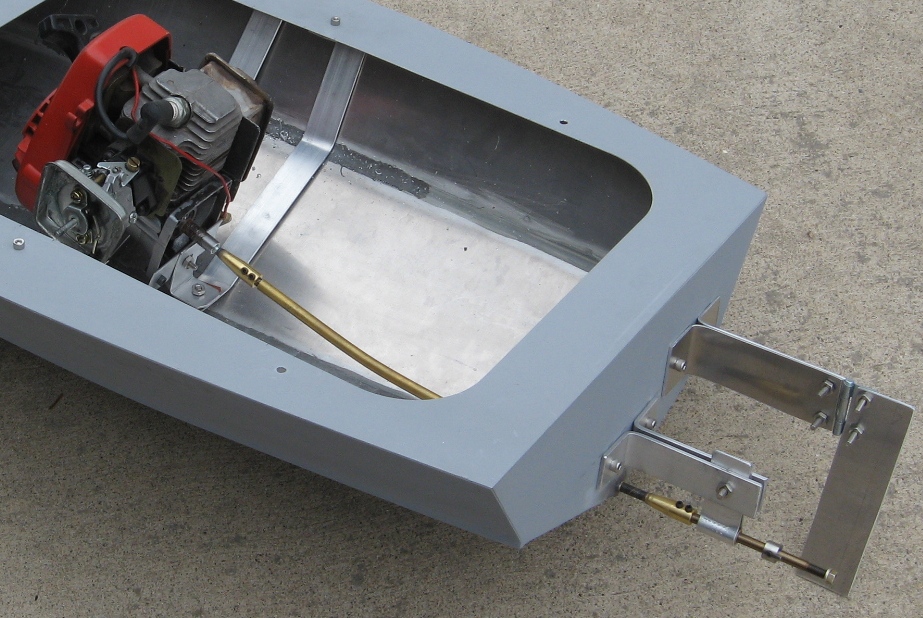

here is some pice of what I did hope it helps

I also made the rudder and the drive strut with aluminum i bought at like home depot or Lowes or a hardware store of sort and a little 1 1/2 inch hinge I bought for like 2 bucks

use brass tube then cut your 1/4 flex cable then use a brass ferrule to attach the cable to the 1/4 stubb shaft and solder the other end to the cable, then buy the drive dog and prop. oh ya and a brass bushing for the shaft to ride in

here is some pice of what I did hope it helps

I also made the rudder and the drive strut with aluminum i bought at like home depot or Lowes or a hardware store of sort and a little 1 1/2 inch hinge I bought for like 2 bucks

Last edit: 14 years 11 months ago by kartrobison.

Please Log in or Create an account to join the conversation.

- kartrobison

- Offline

- Posts: 6

- Thank you received: 0

Time to create page: 0.091 seconds