Rudders & Rudder Mounting Brackets

strictlybusiness1 created the topic: Rudders & Rudder Mounting Brackets

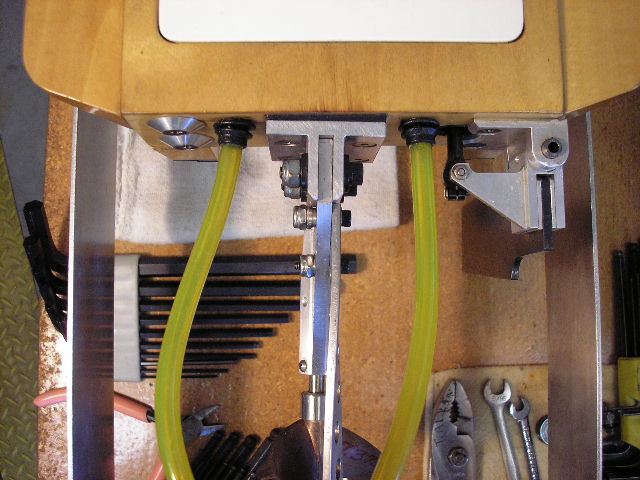

The same rudder mounting bracket is used on various size out riggers, as seen in the photos. The mounting bracket is "cross bolted" to the transom & the side rails by using a tapped 1/8" thick aluminum angle inside the hull, also seen in the photo. In fact the entire transom is "cross bolted" to both side rails!

Rudder blades vary in thickness from 1/4" to 3/16' (aluminum) & 1/8 to 5/64" (hardened & spring tempered steel). All blade types use a 4-40 brass or stainless steel shear screw. All aluminum blades have a sharp inside edge hardened steel insert, seen in the photo, to facilitate clean shearing of the 4-40 shear screw in the event of a rudder strike. Some setups use a rudder blade water pickup & some use dual propeller blast pickups.

Notice the, drilled through, hardened steel, 1/4" pivot pin & the long, brass bushed, bearing area in the rudder blade mounting bracket. All rudder blades are designed to have the leading edge centered on the pivot shafts center line.

Jim Allen

Attachment 625borebarrelcarburetoronQD253.jpg not found

Attachment 625borebarrelcarburetoronQD262.jpg not found

Attachment 625borebarrelcarburetoronQD267.jpg not found

Last edit: 12 years 5 months ago by strictlybusiness1. Reason: add photos

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Topic Author

Topic Author

Steve Seebold replied the topic: Rudders & Rudder Mounting Brackets

Why is the strut in the third picture so far off center?

The following user(s) said Thank You: strictlybusiness1

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

strictlybusiness1 replied the topic: Rudders & Rudder Mounting Brackets

The entire drive train including the engine is setting at a 2* angle with special designed solid mount. The boat runs in a dead straight line with no rudder trim. Solid Titanium shafts with ball & pin universals at the engine, at the end of the stuffing box & before the strut allow any strut depth & angle to be used. The propeller thrust is driven up the shafts into the engines ball bearings by using hardened steel, wear resistant thrust washers between each universal. I believe there is a photo already posted of these simple to machine pieces.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Topic Author

Topic Author

strictlybusiness1 replied the topic: Rudders & Rudder Mounting Brackets

The entire drive train including the engine is setting at a 2* angle with special designed solid mount. The boat runs in a dead straight line with no rudder trim. Solid Titanium shafts with ball & pin universals at the engine, at the end of the stuffing box & before the strut allow any strut depth & angle to be used. The propeller thrust is driven up the shafts into the engines ball bearings by using hardened steel, wear resistant thrust washers between each universal. I believe there is a photo already posted of these simple to machine pieces.

Maybe the photos will explain this better. Everything on the hull is symmetrical except the engine's centerline offset of 1/4" & the 2* angle. The hull runs in a dead straight line at speed with very little rudder area in the water.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Topic Author

Topic Author

Time to create page: 0.281 seconds