Flex Cable Breakage

strictlybusiness1 created the topic: Flex Cable Breakage

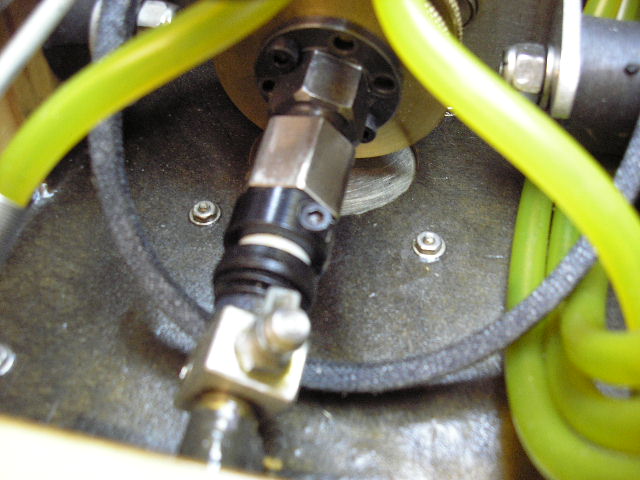

Does anyone think that the, very stiff, 80A durometer, 1.000" diameter, engine mounts & the precision machined single split collets (+-.0002" total indicator run out) used are helping to eliminate any flex cable breakage? Since the total distance between the end of the stuffing tube & the end of the split collet is .625", it is essential, "THAT THE ENGINE STUFFING TUBE ALIGNMENT BE DEAD ON ALSO"!! In fact, this basic requirement would apply to any set up, even if the distance was 1.000" or more! The alignment will become impossible to accomplish if the collet assembly itself is not rotating on center! Using a ground 3.000" long X 1/4" shaft mounted securely in the collet will tell where the stuffing tube engine alignment needs to be & checks the concentricity of the collet assembly.

The black split collar seen in the photo, adjacent to the split collet's clamp nut, does NOT prevent flex cable loss in the event that a flex cable should break. It is only used as a releasing device to remove the cable from the split collet when the clamp nut is backed off.

A small amount of thought can be a wonderful thing in solving model boat problems!

Jim Allen

The black split collar seen in the photo, adjacent to the split collet's clamp nut, does NOT prevent flex cable loss in the event that a flex cable should break. It is only used as a releasing device to remove the cable from the split collet when the clamp nut is backed off.

A small amount of thought can be a wonderful thing in solving model boat problems!

Jim Allen

Last edit: 12 years 6 months ago by strictlybusiness1. Reason: change wording

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Topic Author

Topic Author

whitefish replied the topic: Flex Cable Breakage

I especially like your focus on collet concentricity. Too often, new

collets are installed without being checked.

The method you describe is very effective.

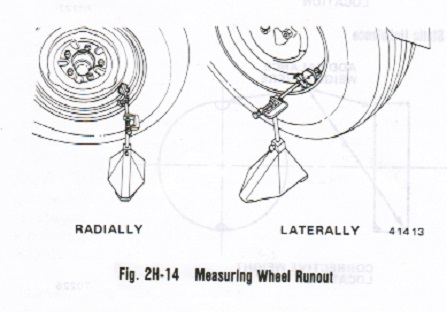

An additional method is to apply a point indicator. Many know what that

term means. For those not familiar with it, this may help:

The steel wheels commonly used in the automotive industry do not break

as often as aluminum wheels but they are know to bend or warp.

To check for warped wheels, the common method is to use an indicator as

shown in the pic.

While the gauge shown might be helpful, many mechanics do this with no

gauge mounted and instead use a simple point indicator (like the tip of

a large awl). They are eyeballing the small space as the wheel is turned

and noting the uniformity of the space (or the variations in the space)

which can tell many mechanics what they want to know quickly.

My point is this same type of examination for concentricity can work

on the collets of our boats. I know for a fact there are collets which

have been sold that have poor concentricity and could easily shorten the

life of any flex cable.

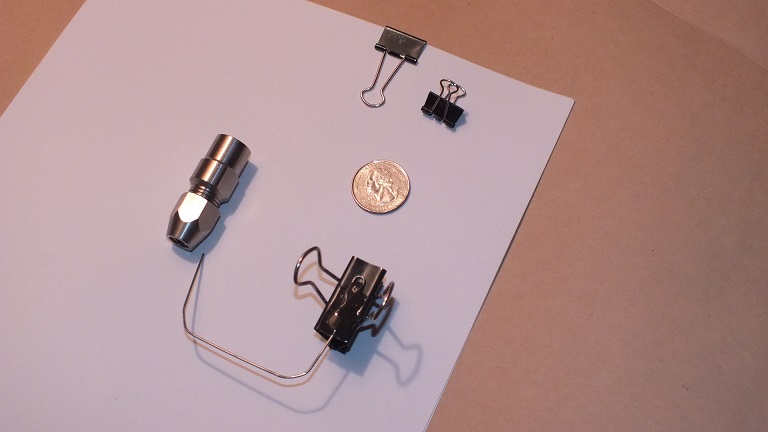

A simple point indicator can be made from two paper clips (both large)

joined with JB Weld.

collets are installed without being checked.

The method you describe is very effective.

An additional method is to apply a point indicator. Many know what that

term means. For those not familiar with it, this may help:

The steel wheels commonly used in the automotive industry do not break

as often as aluminum wheels but they are know to bend or warp.

To check for warped wheels, the common method is to use an indicator as

shown in the pic.

While the gauge shown might be helpful, many mechanics do this with no

gauge mounted and instead use a simple point indicator (like the tip of

a large awl). They are eyeballing the small space as the wheel is turned

and noting the uniformity of the space (or the variations in the space)

which can tell many mechanics what they want to know quickly.

My point is this same type of examination for concentricity can work

on the collets of our boats. I know for a fact there are collets which

have been sold that have poor concentricity and could easily shorten the

life of any flex cable.

A simple point indicator can be made from two paper clips (both large)

joined with JB Weld.

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

strictlybusiness1 replied the topic: Flex Cable Breakage

Thank you for posting something that can be easily done & should be done! I also check the engine collet, flex cable alignment carefully when changing engines, because no manufactured engine mount is precise.

I will post information on how to make the entire end of the flex cable that sits within the collet & the split collar a solid piece, without annealing the spring steel wire used to make the flex cable. Not doing this could cause the clamping force of the collet to bend the flex cable off center.

Jim Allen

I will post information on how to make the entire end of the flex cable that sits within the collet & the split collar a solid piece, without annealing the spring steel wire used to make the flex cable. Not doing this could cause the clamping force of the collet to bend the flex cable off center.

Jim Allen

Attachment 625borebarrelcarburetoronQD107.jpg not found

Last edit: 12 years 7 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Topic Author

Topic Author

Time to create page: 0.080 seconds