Ball Connectors

whitefish created the topic: Ball Connectors

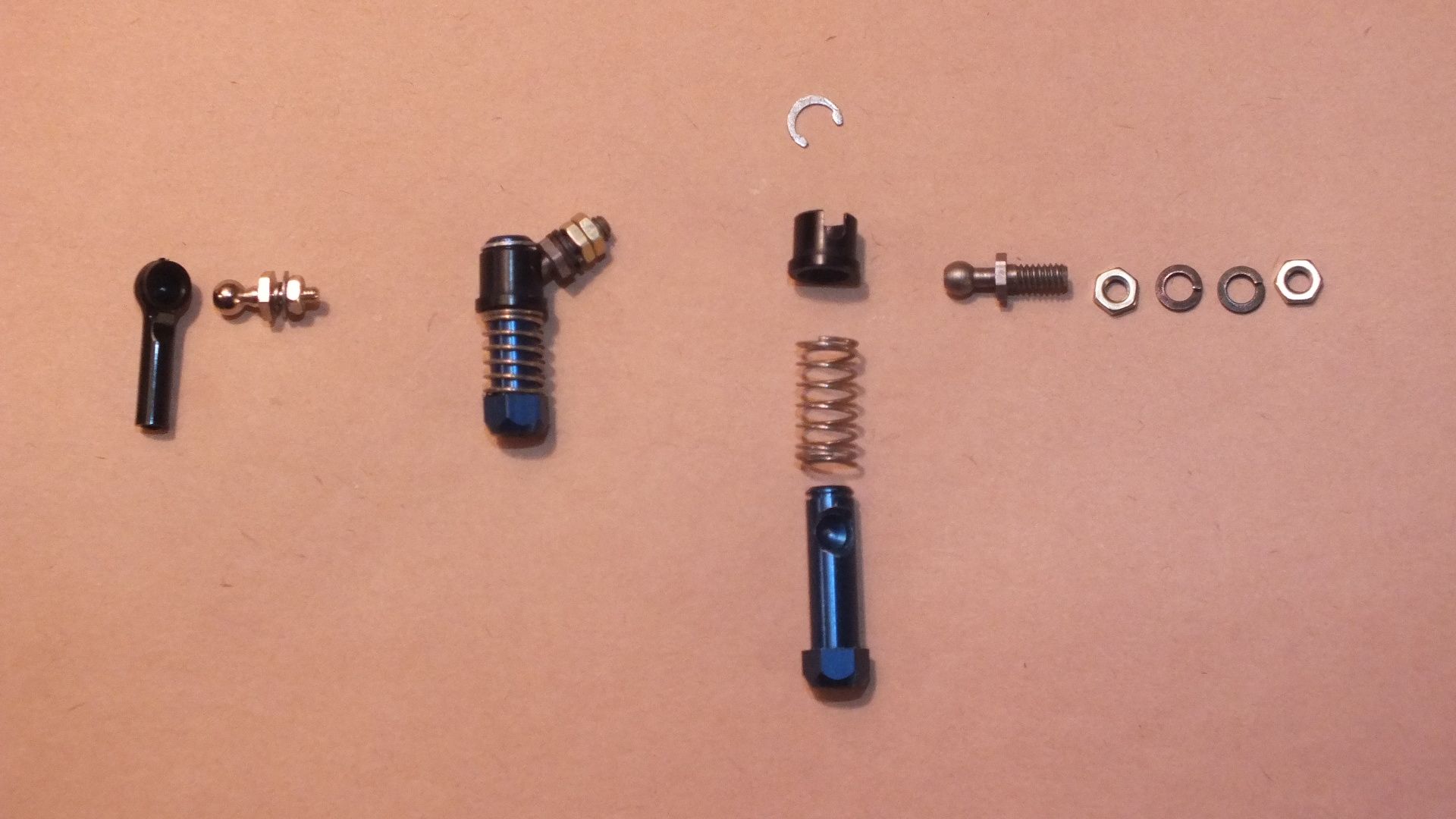

I have a current project that will benefit from using ball connectors

so I have been looking at some of the "quick link" types.

The black one on the left (in the pic) is a simple compact design.

I like everything about it with two exceptions - the pressure required

to insert or remove the ball stub into or from the ball receiver seems

on the high side to me. The other downside is the hex nuts on the ball

stud are smaller than 4-40 hardware.

It may be possible to increase the orifice size slightly and adjust

the pressure - I have not tried. I also wonder if the design could be

improved by using a metal "C" ring to retain the ball in the socket.

Selecting the correct size of ring would control the engage/disengage

tension and with it's smooth, clean look this could easily become a

favorite.

The blue connector is shown assembled in the center and disassembled to

the right. The slide collar release/engage is really slick. Easy to operate

even for those with large hands or limited dexterity. Another feature of

this design is how the spring and collar work together to remove all

slack in the swivel connection. The fit of the ball in the socket is

very precise anyway but with the spring pushing, it is truly a zero slack

ball connector. The threads on the ball stud and threads in the connector

body (blue piece) are 4-40 (three other sizes available). The only downside

is the ball stud and it's hardware is not brass or stainless.

I found these Sullivan ball connectors at Advantage Hobby:

www.advantagehobby.com/

and

www.sullivanproducts.com/Locat...tsMainFrame.htm

The cost is slightly higher for these Sullivans but the convenience and

precision makes it well worth it to me. Until something better comes

along, this design will remain my first choice.

so I have been looking at some of the "quick link" types.

The black one on the left (in the pic) is a simple compact design.

I like everything about it with two exceptions - the pressure required

to insert or remove the ball stub into or from the ball receiver seems

on the high side to me. The other downside is the hex nuts on the ball

stud are smaller than 4-40 hardware.

It may be possible to increase the orifice size slightly and adjust

the pressure - I have not tried. I also wonder if the design could be

improved by using a metal "C" ring to retain the ball in the socket.

Selecting the correct size of ring would control the engage/disengage

tension and with it's smooth, clean look this could easily become a

favorite.

The blue connector is shown assembled in the center and disassembled to

the right. The slide collar release/engage is really slick. Easy to operate

even for those with large hands or limited dexterity. Another feature of

this design is how the spring and collar work together to remove all

slack in the swivel connection. The fit of the ball in the socket is

very precise anyway but with the spring pushing, it is truly a zero slack

ball connector. The threads on the ball stud and threads in the connector

body (blue piece) are 4-40 (three other sizes available). The only downside

is the ball stud and it's hardware is not brass or stainless.

I found these Sullivan ball connectors at Advantage Hobby:

www.advantagehobby.com/

and

www.sullivanproducts.com/Locat...tsMainFrame.htm

The cost is slightly higher for these Sullivans but the convenience and

precision makes it well worth it to me. Until something better comes

along, this design will remain my first choice.

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

Canadian Hot Rod RC Boats replied the topic: Re: Ball Connectors

I'd like to try the blue one's do u have a part number for them ??

Good info thanks

Good info thanks

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

whitefish replied the topic: Re: Ball Connectors

My invoice from Advantage Hobby reads:

SKU: SUL591

Product: 4-40 Aluminum Ball Link with Locking Sleeve (blue)

Price: $6.26

SKU: SUL591

Product: 4-40 Aluminum Ball Link with Locking Sleeve (blue)

Price: $6.26

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

Canadian Hot Rod RC Boats replied the topic: Re: Ball Connectors

Thanks I see

SUL S590 2-56 Threaded Ball Joint

SUL S591 4-40 Threaded Ball Joint

SUL S592 2mm Threaded Ball Joint

SUL S593- NEW 3mm Threaded Ball Joint

Now I can get local hobby shop to order.. Thanks or

www.advantagehobby.com/115682/SULS591/

Randy

SUL S590 2-56 Threaded Ball Joint

SUL S591 4-40 Threaded Ball Joint

SUL S592 2mm Threaded Ball Joint

SUL S593- NEW 3mm Threaded Ball Joint

Now I can get local hobby shop to order.. Thanks or

www.advantagehobby.com/115682/SULS591/

Randy

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Last edit: 13 years 11 months ago by Canadian Hot Rod RC Boats.

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

Time to create page: 0.063 seconds