Wrist Pin Retainer Clips coming off

danielplace1962 replied the topic: Wrist Pin Retainer Clips coming off

The tools I made only work properly if genuine Zenoah clips are used.

Or if the ends are trimmed to same specs.

Built quite a few and have yet to have one come out. I have seen several come out over the years. The cause is defective clips that rotate or not putting them it with the gap straight up or straight down. Install it to either side in the access slot and it will collapse because of the speed at which the piston changes direction collapses the clip if you can believe that.

The biggest cause is over bending the clip during installation. If the clip is fresh new and installed properly the ends should tryb to dig in the aluminum if it tries to rotate.

Or if the ends are trimmed to same specs.

Built quite a few and have yet to have one come out. I have seen several come out over the years. The cause is defective clips that rotate or not putting them it with the gap straight up or straight down. Install it to either side in the access slot and it will collapse because of the speed at which the piston changes direction collapses the clip if you can believe that.

The biggest cause is over bending the clip during installation. If the clip is fresh new and installed properly the ends should tryb to dig in the aluminum if it tries to rotate.

Please Log in or Create an account to join the conversation.

- danielplace1962

- Offline

- Posts: 101

- Karma: 1

- Thank you received: 17

Scoot replied the topic: Wrist Pin Retainer Clips coming off

Daniel, Let me get this correct, the clip gap should be at either the top or at the bottom of the wrist pin, once installed, and not on the side. (eg gap at either 12 oclock or 6 oclock.)

Cheers Scoot.

Cheers Scoot.

Please Log in or Create an account to join the conversation.

- Scoot

- Offline

- Posts: 5

- Thank you received: 0

danielplace1962 replied the topic: Wrist Pin Retainer Clips coming off

Yes sir. You have that correct.

Just to look at it you would think that it would hold best with the most clip in the groove meaning the cli[p gap lined up with the access cutouts. That would probably be true if this clip were anywhere but in a engine like we use them.

The gap of the clip itself should be fully in the piston groove either straight up or straight down.

Please Log in or Create an account to join the conversation.

- danielplace1962

- Offline

- Posts: 101

- Karma: 1

- Thank you received: 17

high-tech replied the topic: Wrist Pin Retainer Clips coming off

Hi Daniel, thanks for the info. I would like to make one of these tools. What sizes of tubing did you use? I did a teardown and noticed one of my clips has the gap where one of the ends is in the space in the piston and I need to fix this before Sunday. We have a club race here in Tucson and I don't want to replace a top end!!!

Please Log in or Create an account to join the conversation.

- high-tech

-

Topic Author

Topic Author

- Offline

- Posts: 15

- Thank you received: 1

strictlybusiness1 replied the topic: Wrist Pin Retainer Clips coming off

For more than 50 years I have successfully used "C" clips of various sizes in various size high performance two cycle gas & nitro engines, without any types of failures. Some of the clips were made by me in the lathe with a mandrel & some were made by outside sources. NONE ever failed & NONE had their openings increased to facilitate insertion!

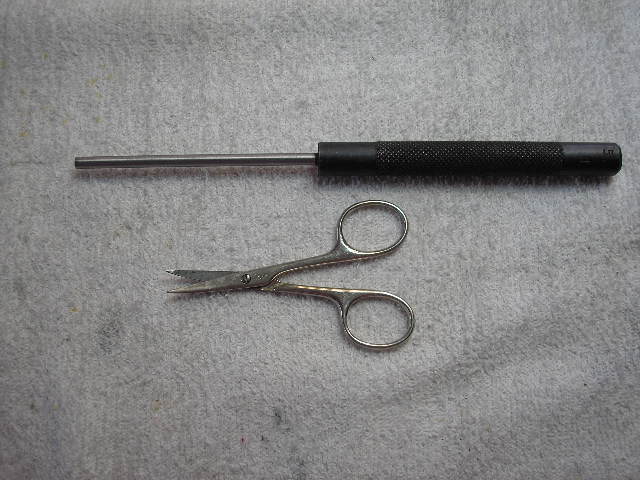

The simple thin walled brass tubes available in your local hobby shop are all that is necessary for easy positive insertion of any size "C" clip! Before inserting the "C" clip, make sure the wrist pin hole has a "smooth, adequate chamfer". A (5/16" -.3125" ID) thin wall brass tubing is chamfered on the outside so that it sits within the chamfered wrist pin hole. Notice that the internal telescoping tubing (5/16" - .3125" OD) passes through the (8mm - .3150") wrist pin hole.

Place the "C" clip inside the larger chamfered tube with it's gap aligned with the black mark on the outside. Use small needle nose pliers so that you can see what is going on. Set the tube & "C" clip firmly down on any flat surface. Insert the inner telescoping tube while holding the chamfered tube down & push. You will now have the "C" clip parallel with the bottom surface of the chamfered tube.

Carefully place the large chamfered tube squarely on the inside chamfered wrist pin hole & push with the telescoping tubing. Since the telescoping tubing fits inside the wrist pin hole, the "C" clip will be inserted squarely without decreasing it's length!

Be aware that floating wrist pins with to much end clearance not only rotate as the engine is running, they will also move in an axial direction with some force. If the wrist pin rotates & it rides against it's "C" clip, that "C" clip will rotate also. In many high performance engines that I build the wrist pins are pressed into their piston bores. This is done with bushed connecting rods. In any case, all wrist pin holes should be finished honed to achieve hole roundness & size. This is very hard to do with a blind wrist pin hole.

Jim Allen

The simple thin walled brass tubes available in your local hobby shop are all that is necessary for easy positive insertion of any size "C" clip! Before inserting the "C" clip, make sure the wrist pin hole has a "smooth, adequate chamfer". A (5/16" -.3125" ID) thin wall brass tubing is chamfered on the outside so that it sits within the chamfered wrist pin hole. Notice that the internal telescoping tubing (5/16" - .3125" OD) passes through the (8mm - .3150") wrist pin hole.

Place the "C" clip inside the larger chamfered tube with it's gap aligned with the black mark on the outside. Use small needle nose pliers so that you can see what is going on. Set the tube & "C" clip firmly down on any flat surface. Insert the inner telescoping tube while holding the chamfered tube down & push. You will now have the "C" clip parallel with the bottom surface of the chamfered tube.

Carefully place the large chamfered tube squarely on the inside chamfered wrist pin hole & push with the telescoping tubing. Since the telescoping tubing fits inside the wrist pin hole, the "C" clip will be inserted squarely without decreasing it's length!

Be aware that floating wrist pins with to much end clearance not only rotate as the engine is running, they will also move in an axial direction with some force. If the wrist pin rotates & it rides against it's "C" clip, that "C" clip will rotate also. In many high performance engines that I build the wrist pins are pressed into their piston bores. This is done with bushed connecting rods. In any case, all wrist pin holes should be finished honed to achieve hole roundness & size. This is very hard to do with a blind wrist pin hole.

Jim Allen

Last edit: 11 years 8 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Scoot replied the topic: Wrist Pin Retainer Clips coming off

Jim,

I have made a similar design with the brass tubing, but, with out the slotted cuts on the bottom of the outer tube, maybe this is causing my failure.....Time to get the dremmel out and experiment !!!!

If all else fails, I might have to see a bloke I know to make me one, eh Dan........

.......Ive just had another look at the pics and I realize its not slotted, but only the texta mark.. !!!!! To early in the morning, 5.30 am, need more coffee !!!!!!

Thanks for the pics, Scoot.

I have made a similar design with the brass tubing, but, with out the slotted cuts on the bottom of the outer tube, maybe this is causing my failure.....Time to get the dremmel out and experiment !!!!

If all else fails, I might have to see a bloke I know to make me one, eh Dan........

.......Ive just had another look at the pics and I realize its not slotted, but only the texta mark.. !!!!! To early in the morning, 5.30 am, need more coffee !!!!!!

Thanks for the pics, Scoot.

Last edit: 11 years 8 months ago by Scoot. Reason: Half asleep, still......

Please Log in or Create an account to join the conversation.

- Scoot

- Offline

- Posts: 5

- Thank you received: 0

strictlybusiness1 replied the topic: Wrist Pin Retainer Clips coming off

You're correct Scoot, even at 5:30 am. This simple procedure works on any size or thickness 'C" clip! Another thing to be aware off includes making sure that the "C" clip is fully inserted in it's groove. A small chamfer on the wrist pin also helps drive the "C" clip deeper in it's groove should the wrist pin begin to float axially to much. I use a good sharp ended drive pin punch after insertion to insure the "C" clip is fully seated. The punch sits against the wrist pin & is rotated with outward pressure around the entire "C" clip. The small curved scissors remove "C" clips without damage to the "C" clip groove or the "C" clip itself. I normally use "C" clips more than once!

Jim Allen

Jim Allen

Last edit: 11 years 8 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Bob DeCortin replied the topic: Wrist Pin Retainer Clips coming off

The bigger question is why is the pin migrating to one side and putting pressure on the clip? that would indicate a number of issues.Full floating pins shouldn't put pressure on the clips.

IF the crank is straight and true and square to the axis of rotation the pin shouldn't move axially.IF the crank is centered to the bore it shouldn't move.IF the rod is straight etc.

BEFORE installing the clip you should check the crank straightness, the deck squareness to the crank, the bore centerline to the big end centerline,bore squareness to the base flange,rod parrallelism.

IF the crank is straight and true and square to the axis of rotation the pin shouldn't move axially.IF the crank is centered to the bore it shouldn't move.IF the rod is straight etc.

BEFORE installing the clip you should check the crank straightness, the deck squareness to the crank, the bore centerline to the big end centerline,bore squareness to the base flange,rod parrallelism.

Please Log in or Create an account to join the conversation.

- Bob DeCortin

- Offline

- Posts: 197

- Karma: 4

- Thank you received: 30

strictlybusiness1 replied the topic: Wrist Pin Retainer Clips coming off

Even if the engine in question was perfectly square in every respect, a full floating wrist pin will move axially as it rotates in the wrist pin's bore. It could move in either direction, back & forth. Effective control of the axial movement can easily be done with a wrist pin that has "C" clips on both sides & closing the clearance to less than .005". This becomes difficult to accomplish with a blind hole which should be honed to size, since it is not possible to hone to the very bottom of that blind hole.

There is also a problem with high performance, high RPM engines where the connecting rod is not guided in the upper end. This would be found in every production engine available & guidance in the bottom end is not an option, because of the very high rotational speed of the crank assembly. Excessive clearance amounts between the piston bosses & the connecting rod will also contribute to wrist pin axial movements.

Jim Allen

JA

There is also a problem with high performance, high RPM engines where the connecting rod is not guided in the upper end. This would be found in every production engine available & guidance in the bottom end is not an option, because of the very high rotational speed of the crank assembly. Excessive clearance amounts between the piston bosses & the connecting rod will also contribute to wrist pin axial movements.

Jim Allen

JA

Last edit: 11 years 8 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

high-tech replied the topic: Wrist Pin Retainer Clips coming off

I'm gonna have to agree with Jim about that axial movement, the proof is in the wear pattern on the wrist pin. I wish I could tear down and look at the insides of the clips and see if I have a significant amount of contact between wrist pin and clip... This morning my boat got stolen out of my car while I walked my dog before going to the lake. So I won't be worrying about this much til I get another built  It's only money right and we need this kind of fun so I will definitely build and build and on and on, I don't think I could ever get my fill of this incredible hobby!!!

It's only money right and we need this kind of fun so I will definitely build and build and on and on, I don't think I could ever get my fill of this incredible hobby!!!

Please Log in or Create an account to join the conversation.

- high-tech

-

Topic Author

Topic Author

- Offline

- Posts: 15

- Thank you received: 1

Time to create page: 0.427 seconds