Build quality from engine builder

RANDYC replied the topic: Build quality from engine builder

Some builders you do get what you paid for and some builders do crappy work and still charge you for guarnteed great performing motor when all the sold you was a guarnteed piece of crap. I'm almost positive I know who is not being mentioned as the guilty party here and I've see the quality of that persons work and you are correct, it's not worth 100 bucks an hour. Heck it's not even worth having the zenoah name on the box once he is done with it. I can't tell you how many time I call Lo and say, he man what the hell is wrong with this motor? His reply is usually, and just how fast were you going when you flipped??? I quickly shut up and say... Oh yea. I'll send it back, just send me a bill to fix it. LOL

Please Log in or Create an account to join the conversation.

- RANDYC

- Offline

- Posts: 5

- Thank you received: 0

CC Racing Engines replied the topic: Build quality from engine builder

Guys,

I have responded to this more then once and deleted it then I actually had a novel typed up that I lost. I figured the easiest way to explain how much time it takes to build a quality engine is to take you through my process. I have built and modified over 3,000 engines. I agree without a doubt that just about anyone with the ability can purchase a Zenoah engine for $225 and I guess in a few hours later with a Dremel and some information posted on this and other sites that you will have a engine that performs better than stock. Do I agree with statements I have read here and other places that in just a few hours time that there is a $400 dollar profit to made with just a Dremel? Absolutely not and that is a statement made by some that just do not know any better. No matter what gets passed around on some of these forums there is a difference in these so called top of the line engines and the guys that know how to tune there boats will make it known who has the good and who has the average junk..

Engine Build:

Bottom End

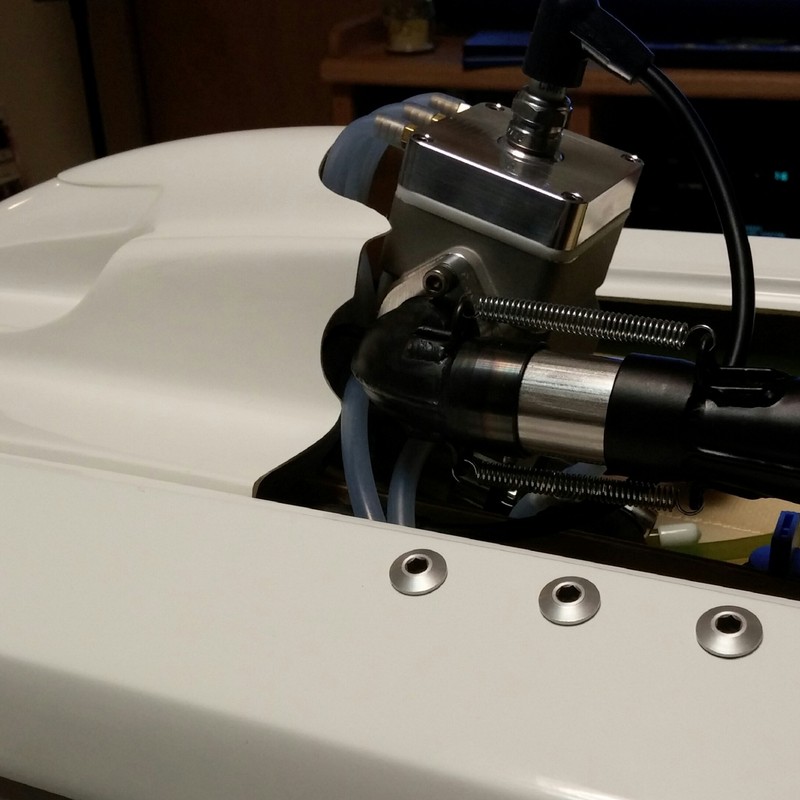

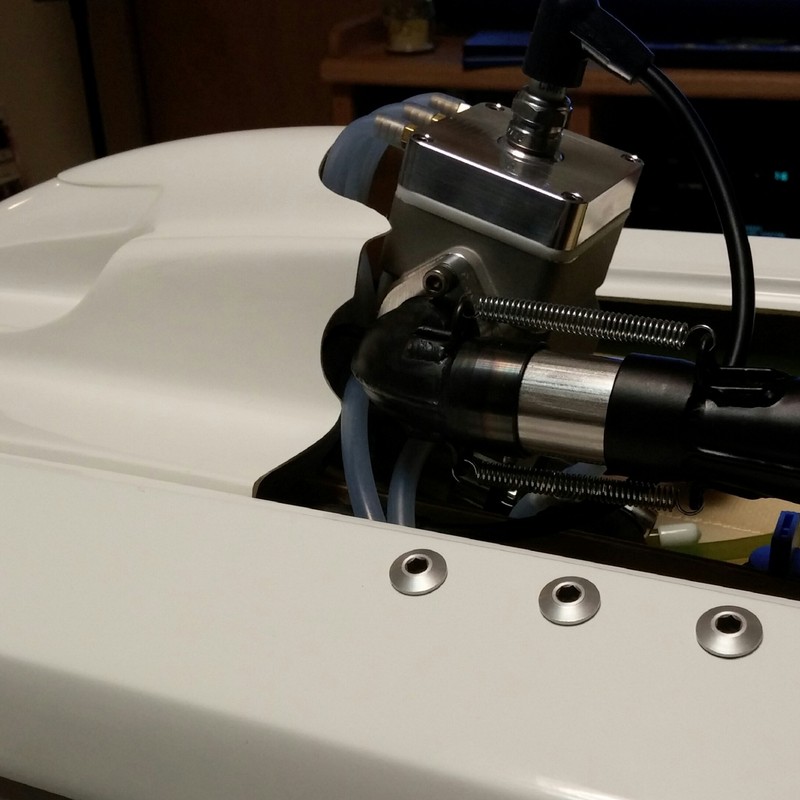

Lets start with completely disassembling the engine and separating all the parts. Take off parts like Carb Blocks, Factory Bolts and champion plugs get thrown in collection bins (If you need any of these let me know I have a couple) . I then take the cylinder and piston and put them in boxes to be shipped out to be CNC machined to my specs and design work. I also take the waterjacket and box it up for laser etching. I then remove the rubber seals from the crankcase halves. Then I thoroughly clean the halves with cleaner to remove any oils that may have gotten on them from assembly or my hand so that when I heat the cases to remove and install new bearings that it does not stain them from the oil residue turning brown. Once they are clean and dry I then heat the case halves to remove the original Zenoah bearings and then replace them with CC Racing Ceramic bearings. I then spray the entire cases with a thin oil to prevent any corrosion and remove the harsh cleaner that we used to clean them with. I then bolt the two halves back together with gasket and crank to check for endplay and to make sure everything is spinning freely. If all checks out I take back apart and install the rubber seals and low drag seals. I then check the crank for straightness and after verification of straightness I install the crank into each half of the crankcase to check for binding. I then get all of the stainless bolts and washers out for the complete build. I lubricate the crank bearings and put the crank in the case halves, bolt it back together again check endplay and make sure nothing is binding. I then machine the flywheel to reduce weight. I clean the flywheel and put a coating over the steel sections to prevent any rust from forming. I then install the key on the crankshaft, install the flywheel, Red Coil, Grey Coil, Front Plate and pullstart with the various stainless bolts and washers. The bottom end is now finished

. I then take the cylinder and piston and put them in boxes to be shipped out to be CNC machined to my specs and design work. I also take the waterjacket and box it up for laser etching. I then remove the rubber seals from the crankcase halves. Then I thoroughly clean the halves with cleaner to remove any oils that may have gotten on them from assembly or my hand so that when I heat the cases to remove and install new bearings that it does not stain them from the oil residue turning brown. Once they are clean and dry I then heat the case halves to remove the original Zenoah bearings and then replace them with CC Racing Ceramic bearings. I then spray the entire cases with a thin oil to prevent any corrosion and remove the harsh cleaner that we used to clean them with. I then bolt the two halves back together with gasket and crank to check for endplay and to make sure everything is spinning freely. If all checks out I take back apart and install the rubber seals and low drag seals. I then check the crank for straightness and after verification of straightness I install the crank into each half of the crankcase to check for binding. I then get all of the stainless bolts and washers out for the complete build. I lubricate the crank bearings and put the crank in the case halves, bolt it back together again check endplay and make sure nothing is binding. I then machine the flywheel to reduce weight. I clean the flywheel and put a coating over the steel sections to prevent any rust from forming. I then install the key on the crankshaft, install the flywheel, Red Coil, Grey Coil, Front Plate and pullstart with the various stainless bolts and washers. The bottom end is now finished

Top End

I then get a finished CNC machined piston out of the box debur it from the machine work and thoroughly clean it. I lubricate the wristpin bearing and install the piston on the rod with new clips. I then install the ring check to make sure it moves freely in the ring land and then check to make sure the piston moves freely on the rod and has adequate side to side movement. Next I take the copper base gasket and lightly coat it with the sealant I use and place it on bottom end. I then disassemble the carb and bolt it to my fixture and modify and radius it to my specs. I then thoroughly clean the carb with cleaner and lubricate everything and reassemble. I then set the adjustment on the high and low needles and install the needle clamp. I then take the teflon gaskets for the CC Racing billet carb block and clean the residue left from the laser cutter. I then get the NGK plug, water-jacket screws and carb block screws together for a small coating of never seize. I then get a CNC cylinder and start the finish work by hand. I have four digital Dremels with different carbide bits that I use to get the correct angles and shapes for each cylinder. Once I finish the port work and check all of port specifications I put the finish grain on the ports that I have found works the best through my years of testing and running. I then use another digital Dremel that I have a special deburring wheel for deburring all the ports. The cylinder then gets blown out and sprayed with cleaner and blown out again to make sure it is spotless. I then install the cylinder on the bottom end and lubricate the piston on each side through the exhaust and intake port and make sure that it turns over freely with no type of binding. I then install the water-jacket o rings and the water-jacket. The NGK plug gets installed next followed by the carb block and the modified carb. Then the entire engine gets a quick inspection and a couple pulls on the starter rope to make sure everything is good to go and then it gets a serial number engraved on the bottom which is my seal of approval. It then gets put back in the bag that it came in and gets shipped out to the customer for some fun in the sun. It is ready to brake records and win races.

This process usually takes me between 7 to 8 hours and I am not that slow I have been doing this for a little while now (Since 1996, yeah 18 years). This has nothing to do with the time or fees involved with shipping cylinders, pistons, water-jackets out to be machined or any of the support parts added to the engine to make it a quality piece.

Here are some parts that need to be deducted from that imaginary $400 dollar profit margin:

Ceramic Bearings

Low Drag Seals

Copper Base Gasket

Stainless Fasteners

NGK Plug

Needle Clamp

Billet Carb Block

Cleaners

Sealant

Never seize

Lubricant

Flywheel Coating

18 years of experience and support that comes with the engine.

(Lets not mention the lathes, mills and specialty tools used in any of this )

)

If you think that anyone that is doing these engines right is gonna get rich anytime soon you need to think again. The profit margin after everything is said and done is not that much and you have to really love what you are doing to continue doing this stuff. There is a new guy doing this stuff every other month that all of a sudden have it all figured out and has the best stuff since sliced bread. They read the how too articles, order a couple bits online, go get themselves a Dremel from Home Depot and do there best to copy what they have seen in pictures online and bam we have another engine builder selling engines that knows absolutely nothing. The results are always similar or usually worse then what you see in the posts that started this thread.

Carlo

I have responded to this more then once and deleted it then I actually had a novel typed up that I lost. I figured the easiest way to explain how much time it takes to build a quality engine is to take you through my process. I have built and modified over 3,000 engines. I agree without a doubt that just about anyone with the ability can purchase a Zenoah engine for $225 and I guess in a few hours later with a Dremel and some information posted on this and other sites that you will have a engine that performs better than stock. Do I agree with statements I have read here and other places that in just a few hours time that there is a $400 dollar profit to made with just a Dremel? Absolutely not and that is a statement made by some that just do not know any better. No matter what gets passed around on some of these forums there is a difference in these so called top of the line engines and the guys that know how to tune there boats will make it known who has the good and who has the average junk..

Engine Build:

Bottom End

Lets start with completely disassembling the engine and separating all the parts. Take off parts like Carb Blocks, Factory Bolts and champion plugs get thrown in collection bins (If you need any of these let me know I have a couple)

Top End

I then get a finished CNC machined piston out of the box debur it from the machine work and thoroughly clean it. I lubricate the wristpin bearing and install the piston on the rod with new clips. I then install the ring check to make sure it moves freely in the ring land and then check to make sure the piston moves freely on the rod and has adequate side to side movement. Next I take the copper base gasket and lightly coat it with the sealant I use and place it on bottom end. I then disassemble the carb and bolt it to my fixture and modify and radius it to my specs. I then thoroughly clean the carb with cleaner and lubricate everything and reassemble. I then set the adjustment on the high and low needles and install the needle clamp. I then take the teflon gaskets for the CC Racing billet carb block and clean the residue left from the laser cutter. I then get the NGK plug, water-jacket screws and carb block screws together for a small coating of never seize. I then get a CNC cylinder and start the finish work by hand. I have four digital Dremels with different carbide bits that I use to get the correct angles and shapes for each cylinder. Once I finish the port work and check all of port specifications I put the finish grain on the ports that I have found works the best through my years of testing and running. I then use another digital Dremel that I have a special deburring wheel for deburring all the ports. The cylinder then gets blown out and sprayed with cleaner and blown out again to make sure it is spotless. I then install the cylinder on the bottom end and lubricate the piston on each side through the exhaust and intake port and make sure that it turns over freely with no type of binding. I then install the water-jacket o rings and the water-jacket. The NGK plug gets installed next followed by the carb block and the modified carb. Then the entire engine gets a quick inspection and a couple pulls on the starter rope to make sure everything is good to go and then it gets a serial number engraved on the bottom which is my seal of approval. It then gets put back in the bag that it came in and gets shipped out to the customer for some fun in the sun. It is ready to brake records and win races.

This process usually takes me between 7 to 8 hours and I am not that slow I have been doing this for a little while now (Since 1996, yeah 18 years). This has nothing to do with the time or fees involved with shipping cylinders, pistons, water-jackets out to be machined or any of the support parts added to the engine to make it a quality piece.

Here are some parts that need to be deducted from that imaginary $400 dollar profit margin:

Ceramic Bearings

Low Drag Seals

Copper Base Gasket

Stainless Fasteners

NGK Plug

Needle Clamp

Billet Carb Block

Cleaners

Sealant

Never seize

Lubricant

Flywheel Coating

18 years of experience and support that comes with the engine.

(Lets not mention the lathes, mills and specialty tools used in any of this

If you think that anyone that is doing these engines right is gonna get rich anytime soon you need to think again. The profit margin after everything is said and done is not that much and you have to really love what you are doing to continue doing this stuff. There is a new guy doing this stuff every other month that all of a sudden have it all figured out and has the best stuff since sliced bread. They read the how too articles, order a couple bits online, go get themselves a Dremel from Home Depot and do there best to copy what they have seen in pictures online and bam we have another engine builder selling engines that knows absolutely nothing. The results are always similar or usually worse then what you see in the posts that started this thread.

Carlo

www.rcbwc.com

Ego Means Nothing

Talent Means Something

Heart Means Everything

Don't believe what you hear

Believe what you see.

Carlo Catalanotto

www.ccracingengines.com

This email address is being protected from spambots. You need JavaScript enabled to view it.

1-504-304-5077

Last edit: 11 years 10 months ago by CC Racing Engines.

Please Log in or Create an account to join the conversation.

- CC Racing Engines

-

- Offline

- Vendor ...

- Posts: 149

- Thank you received: 23

RANDYC replied the topic: Build quality from engine builder

And that's why I buy a quality product from you because is has a guarntee that it's a top performer. You don't just take a dump in a box and call it guarnteed because you have time to like other do  . As for doing it for pennies, he's right. He charges .07 cents more that others for this guarntee.

. As for doing it for pennies, he's right. He charges .07 cents more that others for this guarntee.

Please Log in or Create an account to join the conversation.

- RANDYC

- Offline

- Posts: 5

- Thank you received: 0

SRI Motorsports replied the topic: Build quality from engine builder

So Carlo, now that you have made it clear that my old man and I build crap, how much will it cost me for 6 new engines. Lol. J/k buddy. Everything listed is very accurate. Most guys dont know how much time and money it takes to build quality. I have said it before and will again, If we didn't have our own eng design and program you would be our builder. With that being said, when it comes to pistons and other random parts, I run Carlo's stuff as much as I can. He has never given me crap that I have had to fix. I encourage anyone if they can, to choose a honest builder that enjoys what they do, not in it for a buck. CC Racing or Quick Draw in my books. Nothing else.

Peter Somers

SRI Motorsports

Lazer 40 LSG27 + LSG36 SAW

Last edit: 11 years 10 months ago by SRI Motorsports.

Please Log in or Create an account to join the conversation.

- SRI Motorsports

-

- Offline

- Posts: 61

- Thank you received: 7

tootalltechie replied the topic: Build quality from engine builder

I am not an engine builder but a hobbyist. I don't race but I like to make things work better.

Here is a question or two...

If I was to send an engine to get worked on should I send the the total exhaust system?

Or should the engine builder know the exhaust being used and build accordingly?

If the engine is going in a boat should the engine builder be a "boat guy"

What information does the engine builder need to know about the boat?

How do you find a good engine builder if you are new to the hobby?

Gordon

Here is a question or two...

If I was to send an engine to get worked on should I send the the total exhaust system?

Or should the engine builder know the exhaust being used and build accordingly?

If the engine is going in a boat should the engine builder be a "boat guy"

What information does the engine builder need to know about the boat?

How do you find a good engine builder if you are new to the hobby?

Gordon

Please Log in or Create an account to join the conversation.

- tootalltechie

-

- Offline

- Posts: 177

- Karma: 5

- Thank you received: 20

Hendo replied the topic: Build quality from engine builder

Well said Carlo.

Please Log in or Create an account to join the conversation.

- Hendo

-

- Offline

- Posts: 22

- Thank you received: 0

CC Racing Engines replied the topic: Build quality from engine builder

Randy,

you and your family is the only group that gets the 7 cent upcharge for the warranty.

Peter,

Thanks for the kind words and your support.

Tim,

Thanks man.

Gordon,

I am kind of glad you asked those questions and I will give you my opinion on the subject. Whichever engine guy you choose should not need your exhaust or even know what it is to build you a engine. The engine should be built to be as efficient as possible no matter what pipe is on it.

Your exhaust is what determines the power curve of your engine and how soon it turns on and also how soon it falls off the power curve. Different pipes give engines different characteristics and you can simulate the pipe to the engines personality as certain pipes will cause engines to act differently. Some boats will require different pipes to perform well and you need to find the pipe that best fits your combination. On most of the race boats that we run (Small, Lightweight, High Efficiency with plenty of airflow) I have not found any pipe that outperforms a good steel pipe plain and simple. The fact remains that some boats can not deal with the heat issues that come with steel pipes and your only option is an aluminum pipe to run well. You always have to remember that everything must work in conjunction with each other to be successful. The reason that 2" band style aluminum pipes are so popular is the fact that they are a lot more forgiving to setups that might not be perfect because of a lower RPM broad power curve. You could have a boat with a steel pipe and a prop that is just a little too big that just will not run well no matter what adjustments you make and you bolt on a Aluminum pipe that puts the torque a little lower in the RPM range more suited for the bigger prop and the boat will pick up and run well. The other option would be to switch to a little smaller prop and use the better over rev characteristics of the steel pipe to get the boat to run well. Everything is a give and take and as always test and tuning is very important.

I think it is very important for a engine guy to know about boats as it is the only way to know how to help your customers if they have a problem. Contrary to popular belief and of course it is just my opinion, but if you have a engine guy tell you that they are going to build you a engine to fit the style of boat you are running and they are going to adjust the timing numbers to match the type of hull you are going to use then put your running shoes on and head for the hills and never look back as they truly have no idea what they are doing. You should always build a engine to make the most power across the broadest RPM range. Once that combination is found you do not raise or lower any of the timing or change port shapes to suit a certain style hull. You prop and pipe the boat to use the engine with the maximum efficiency that the engine makes not the opposite. In any form of racing you build the most power you can with your powerplant and build everything else to support it and make it usable. The timing numbers you always see and read about that guys love to discuss mean absolutely nothing and are nothing more then a reference point and comparing those numbers from one guy to another without knowing how the port is shaped is just laughable and ridiculous especially with the bigger is better thought process that has been running rampant with some engine modifiers lately. I run the same exact engine in my Sport Hydro as I run in my Mono or my Cat no changes to anything. Believe it or not the cylinders that are on all of our straight-line and 2 lap record setting engines that have set numerous world records are identical to what I run and sell to my customers on there heat race engines.

When considering engine guys ask if they have a dyno (If they are serious about this kind of work they will invest in a dyno good or bad)? Ask how long they have been doing it? Ask if they actually run or race boats? Check around to see if they are reputable and remember every circle has there own clicks, but that does not mean that the people they recommend will be the best or will suite your needs so check around and chose someone you can work with if you have issues. If they know nothing about boats or running them then they will not be much help to you if you have a setup problem.

Good Luck

Carlo

you and your family is the only group that gets the 7 cent upcharge for the warranty.

Peter,

Thanks for the kind words and your support.

Tim,

Thanks man.

Gordon,

I am kind of glad you asked those questions and I will give you my opinion on the subject. Whichever engine guy you choose should not need your exhaust or even know what it is to build you a engine. The engine should be built to be as efficient as possible no matter what pipe is on it.

Your exhaust is what determines the power curve of your engine and how soon it turns on and also how soon it falls off the power curve. Different pipes give engines different characteristics and you can simulate the pipe to the engines personality as certain pipes will cause engines to act differently. Some boats will require different pipes to perform well and you need to find the pipe that best fits your combination. On most of the race boats that we run (Small, Lightweight, High Efficiency with plenty of airflow) I have not found any pipe that outperforms a good steel pipe plain and simple. The fact remains that some boats can not deal with the heat issues that come with steel pipes and your only option is an aluminum pipe to run well. You always have to remember that everything must work in conjunction with each other to be successful. The reason that 2" band style aluminum pipes are so popular is the fact that they are a lot more forgiving to setups that might not be perfect because of a lower RPM broad power curve. You could have a boat with a steel pipe and a prop that is just a little too big that just will not run well no matter what adjustments you make and you bolt on a Aluminum pipe that puts the torque a little lower in the RPM range more suited for the bigger prop and the boat will pick up and run well. The other option would be to switch to a little smaller prop and use the better over rev characteristics of the steel pipe to get the boat to run well. Everything is a give and take and as always test and tuning is very important.

I think it is very important for a engine guy to know about boats as it is the only way to know how to help your customers if they have a problem. Contrary to popular belief and of course it is just my opinion, but if you have a engine guy tell you that they are going to build you a engine to fit the style of boat you are running and they are going to adjust the timing numbers to match the type of hull you are going to use then put your running shoes on and head for the hills and never look back as they truly have no idea what they are doing. You should always build a engine to make the most power across the broadest RPM range. Once that combination is found you do not raise or lower any of the timing or change port shapes to suit a certain style hull. You prop and pipe the boat to use the engine with the maximum efficiency that the engine makes not the opposite. In any form of racing you build the most power you can with your powerplant and build everything else to support it and make it usable. The timing numbers you always see and read about that guys love to discuss mean absolutely nothing and are nothing more then a reference point and comparing those numbers from one guy to another without knowing how the port is shaped is just laughable and ridiculous especially with the bigger is better thought process that has been running rampant with some engine modifiers lately. I run the same exact engine in my Sport Hydro as I run in my Mono or my Cat no changes to anything. Believe it or not the cylinders that are on all of our straight-line and 2 lap record setting engines that have set numerous world records are identical to what I run and sell to my customers on there heat race engines.

When considering engine guys ask if they have a dyno (If they are serious about this kind of work they will invest in a dyno good or bad)? Ask how long they have been doing it? Ask if they actually run or race boats? Check around to see if they are reputable and remember every circle has there own clicks, but that does not mean that the people they recommend will be the best or will suite your needs so check around and chose someone you can work with if you have issues. If they know nothing about boats or running them then they will not be much help to you if you have a setup problem.

Good Luck

Carlo

www.rcbwc.com

Ego Means Nothing

Talent Means Something

Heart Means Everything

Don't believe what you hear

Believe what you see.

Carlo Catalanotto

www.ccracingengines.com

This email address is being protected from spambots. You need JavaScript enabled to view it.

1-504-304-5077

Last edit: 11 years 10 months ago by CC Racing Engines.

Please Log in or Create an account to join the conversation.

- CC Racing Engines

-

- Offline

- Vendor ...

- Posts: 149

- Thank you received: 23

SRI Motorsports replied the topic: Build quality from engine builder

Perfect responce Carlo. Good question Gordon.

Peter Somers

SRI Motorsports

Lazer 40 LSG27 + LSG36 SAW

Please Log in or Create an account to join the conversation.

- SRI Motorsports

-

- Offline

- Posts: 61

- Thank you received: 7

Hot Rods replied the topic: Build quality from engine builder

Timing #s are just THAT; numbers. In any form of extreme motor sports, flow and flow control, make or break the power of any engine. No matter if it's a 25cc or a 500 ci TF. They are all air pumps, with fuel and spark added to create movement. I know, I know; that's obvious! But you'd be amazed at how many lose sight of that.

Please Log in or Create an account to join the conversation.

- Hot Rods

-

- Offline

- Posts: 164

- Karma: -5

- Thank you received: 36

Hendo replied the topic: Build quality from engine builder

So Carlo , what did you say those Timing #'s were again ?? LOl

Please Log in or Create an account to join the conversation.

- Hendo

-

- Offline

- Posts: 22

- Thank you received: 0

Time to create page: 0.080 seconds