flywheel

dodol created the topic: flywheel

Howto balance a flywheel with very simple tools?

and it is needed to balance flywheel with crankshaft together? or each working independently?

and it is needed to balance flywheel with crankshaft together? or each working independently?

Please Log in or Create an account to join the conversation.

- dodol

- Offline

- Posts: 31

- Thank you received: 1

strictlybusiness1 replied the topic: flywheel

The only instance of balancing the crankshaft with a flywheel or an airplane propeller driver would be found on a front intake engine which has a large intake window in a large diameter crankshaft. On a boat engine the balancing is done on the outside of the flywheel or the back side of the flywheel. On an airplane engine the balancing is done on the back side of the spinner mount. No other balancing of a concentric machined flywheel is necessary providing identical cuts are 180* apart, 120* apart, 90* apart, etc.

Jim Allen

Jim Allen

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

dodol replied the topic: flywheel

do you mean for boat engine, balancing should be done with flywheel and crankshaft inside engine?

can we take the flywheel out and do balancing separately?

can we take the flywheel out and do balancing separately?

Please Log in or Create an account to join the conversation.

- dodol

- Offline

- Posts: 31

- Thank you received: 1

danielplace1962 replied the topic: flywheel

You are talking about a magneto type(with magnets)flywheel off of a gasoline engine, correct?

Yes the flywheel can be balanced off the crank with a non magnetic balancer just like we do props.

The first step is to true the faces to the shaft on a lathe. Grind a key in half and install that in the keyway slot when doing the balancing.

Be certain there is no metal whatsoever within the work area when you are checking the balance.

Yes the flywheel can be balanced off the crank with a non magnetic balancer just like we do props.

The first step is to true the faces to the shaft on a lathe. Grind a key in half and install that in the keyway slot when doing the balancing.

Be certain there is no metal whatsoever within the work area when you are checking the balance.

Last edit: 11 years 11 months ago by danielplace1962.

Please Log in or Create an account to join the conversation.

- danielplace1962

- Offline

- Posts: 101

- Karma: 1

- Thank you received: 17

strictlybusiness1 replied the topic: flywheel

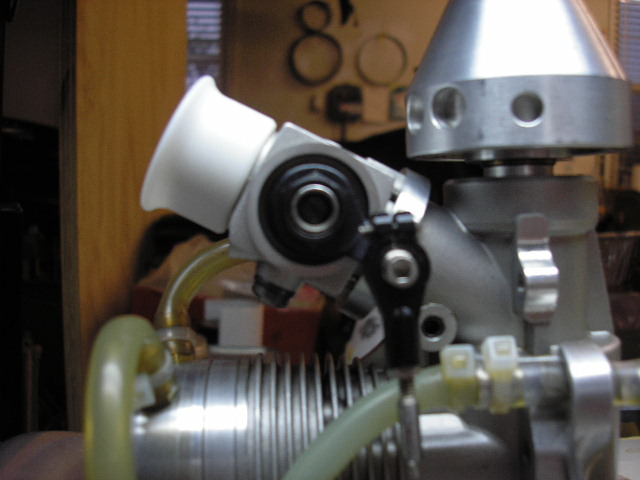

If a magneto type flywheel is to be balanced, a balancer similar to the one shown in the lower right hand corner of the photo should be used. An explanation of how it works can be found on the Bolly site. A matching taper to the flywheel's taper is machined in the top piece & since both pieces are made of aluminum there are no magnetism problems to consider. The balancer can balance in two planes at the same time, which is impossible with magnetic or spin type balancers.

Jim Allen

Jim Allen

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

danielplace1962 replied the topic: flywheel

How did I already know however it is that I suggest to do something you have the only right way to do it.

Balancing on a properly made "spin type" balancer balances the flywheels perfectly.

If it works for props spinning 18,000 rpm it is no different for a flywheel. Been balancing them this way for years and it works wonderfully.

The difference in balance from the front face to the rear face is irrelevant really being they are only 1" apart and spinning on a 12mm thick shaft. If it spins perfectly balanced it will not vibrate at high rpm. Everyone I do clearly changes the vibration that flywheels can create when they aren't perfect. Stock ones are not bad but they are not perfect. If they can be out as much as they are and function

getting them considerably better can only be a good thing. Especially since it is the front bearing that is already taking all the force from the prop pushing on it. No sense having the flywheel beating up on it to.

What your showing is still just a static balance.

Balancing on a properly made "spin type" balancer balances the flywheels perfectly.

If it works for props spinning 18,000 rpm it is no different for a flywheel. Been balancing them this way for years and it works wonderfully.

The difference in balance from the front face to the rear face is irrelevant really being they are only 1" apart and spinning on a 12mm thick shaft. If it spins perfectly balanced it will not vibrate at high rpm. Everyone I do clearly changes the vibration that flywheels can create when they aren't perfect. Stock ones are not bad but they are not perfect. If they can be out as much as they are and function

getting them considerably better can only be a good thing. Especially since it is the front bearing that is already taking all the force from the prop pushing on it. No sense having the flywheel beating up on it to.

What your showing is still just a static balance.

Last edit: 11 years 11 months ago by danielplace1962.

Please Log in or Create an account to join the conversation.

- danielplace1962

- Offline

- Posts: 101

- Karma: 1

- Thank you received: 17

strictlybusiness1 replied the topic: flywheel

If the difference between the front face & the rear face of a propeller spinning at 13,000 to 18,000 RPM is .636" X 1.448" hub diameter, what could happen with a .900" thick piece X 2.358" in diameter spinning at the same RPM, considering the flywheel weighs 7.3 ounces & the propeller weighs 1.4 ounces? Yes, it is a static balancer, but it can balance in two planes at the same time. A magnetic or spin type balancer can balance in only one plane!

Unfounded assumptions about mechanical things are dangerous! Remember your posted quote, "I have run the APC props to over 21,000 RPM and endlessly at 18,000 RPM yet to have one fail."

Here's another one, "Especially since it is the front bearing that is already taking all the force from the prop pushing on it. No sense having the flywheel beating up on it to."

Jim Allen

Unfounded assumptions about mechanical things are dangerous! Remember your posted quote, "I have run the APC props to over 21,000 RPM and endlessly at 18,000 RPM yet to have one fail."

Here's another one, "Especially since it is the front bearing that is already taking all the force from the prop pushing on it. No sense having the flywheel beating up on it to."

Jim Allen

Last edit: 11 years 11 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

danielplace1962 replied the topic: flywheel

These are not unfounded assumptions. These are facts. Your the one that is full of assumptions. If it isn't something Jim is doing his way then it is not ever right. We understand your assumptions quite well.

Where do you figure either comment is an assumption. It is fact.

Fact,

Yes and I am still running the same props and haven't had one fail yet. Stating what rpm a prop is working at for me is NO assumption !

Your idea that is would fail is a assumption. A incorrect assumption !

What do you want a video of the test stand with the APC prop on it wrung out over 18,000 rpm. I can provide that if it would make it clearer that it works perfectly and the props are 3-4 years old already and no I haven't had a single one come apart yet with many hours of endless wide open running at extremely high rpm's.

Fact,

It is the front bearing that is taking the load from the prop force when running a round collet and welded stub cable? It is positively the front bearings inner race that the crank is trying to push out the front of the engine. The same bearing that is 1/4" behind the flywheel. The front bearing takes the load of both of these items working and loading it.

So you don't think an out of balance flywheel puts more wear and tear on the front bearing that is already taking the prop thrust ?

Last edit: 11 years 11 months ago by danielplace1962.

Please Log in or Create an account to join the conversation.

- danielplace1962

- Offline

- Posts: 101

- Karma: 1

- Thank you received: 17

strictlybusiness1 replied the topic: flywheel

Here's a fact for those that may have some understanding about balancing a magneto type flywheel & what effect it has on bearing performance. What happens when the flywheel is balanced & it is mounted on a crankshaft that has not been trued? I'm sure we will here more gibberish about how trueing can be done in that "precision" three jaw chuck referred to many times in the past. Whatever makes you & your un-suspecting customers happy is cool.

Radial type ball bearings are designed to accept both radial & axial loads. This is also a fact! Ratings can be found in any bearing catalogue.

Jim Allen

Radial type ball bearings are designed to accept both radial & axial loads. This is also a fact! Ratings can be found in any bearing catalogue.

Jim Allen

Last edit: 11 years 11 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

Time to create page: 0.155 seconds