Tiger King 27cc Engine Making Waves

Dave Marles replied the topic: Tiger King 27cc Engine Making Waves

In two strokes a barrier coating on the piston will reduce the temperature of the underside of the piston which will reduce the temperature of the mixture in the crankcase. This will increase the density of the mixture and so improve power output. That is the theory given by the 2 stroke experts as far as I have seen.. Have I proven the theory, the answer is no. Does it sound feasible. Yes.

Regarding the cylinder material...If it is cast iron then there is no problem, that is a standard material for cylinder liners. I have asked the question of TK but they take a long time to reply.

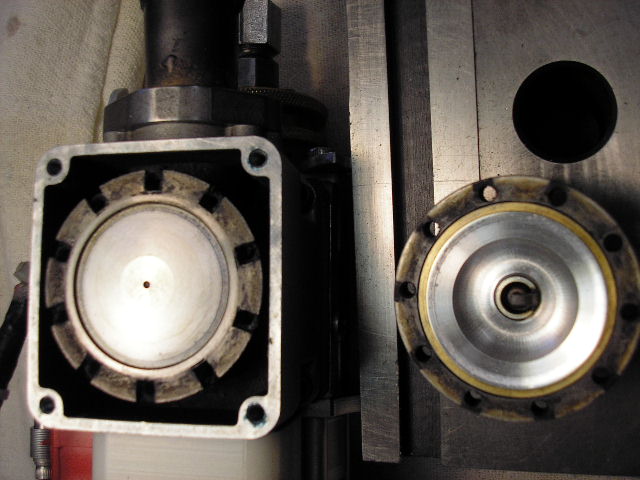

One thing is for certain is that the thick liner in this engine along with the thick cylinder block casting is keeping the cylinder round unlike many other marine motors I have used. After a lot of hard running there is zero blowby on the piston.

Dave

Regarding the cylinder material...If it is cast iron then there is no problem, that is a standard material for cylinder liners. I have asked the question of TK but they take a long time to reply.

One thing is for certain is that the thick liner in this engine along with the thick cylinder block casting is keeping the cylinder round unlike many other marine motors I have used. After a lot of hard running there is zero blowby on the piston.

Dave

Please Log in or Create an account to join the conversation.

- Dave Marles

- Offline

- Posts: 25

- Karma: 8

- Thank you received: 6

Hot Rods replied the topic: Tiger King 27cc Engine Making Waves

Maintaining a perfectly round cyld. is always a good path to power, and so a thick liner is a plus for sure. The same holds for final honing of the sleeve as installed, with a torque plate torqued down to simulate the upper cyld. distortion from the button bolts.

I can agree with the theory of a cooler underside of the piston helping to keep the fuel charge more dense. But I can see that helping perhaps on a much slower running assembly. On our tiny engines, the fuel mixing is taking place a VERY short distance from the case, and at 17 to 20K rpm, I have a hard time seeing there being enough time for the fuel to be heated at all, before it's combusted. From the carb to the chamber, it only has to travel a few centimeters, in an extremely short period of time. On much larger displacement and multi cyld. 2 strokes, the piston's undercrown area is many times larger than ours. And that may be where the theory would show some measurable differences. Not many 2 stroke experts test on 25 to 30cc. engines.

Just some thoughts.

I can agree with the theory of a cooler underside of the piston helping to keep the fuel charge more dense. But I can see that helping perhaps on a much slower running assembly. On our tiny engines, the fuel mixing is taking place a VERY short distance from the case, and at 17 to 20K rpm, I have a hard time seeing there being enough time for the fuel to be heated at all, before it's combusted. From the carb to the chamber, it only has to travel a few centimeters, in an extremely short period of time. On much larger displacement and multi cyld. 2 strokes, the piston's undercrown area is many times larger than ours. And that may be where the theory would show some measurable differences. Not many 2 stroke experts test on 25 to 30cc. engines.

Just some thoughts.

Last edit: 11 years 11 months ago by Hot Rods.

Please Log in or Create an account to join the conversation.

- Hot Rods

-

- Offline

- Posts: 164

- Karma: -5

- Thank you received: 36

Dave Marles replied the topic: Tiger King 27cc Engine Making Waves

TK have confirmed to me this morning that the cylinder is in fact a special iron and the coating on the piston is a thermal barrier coating.

Dennis, regarding the theory of the barrier coating, I can only pass on what I have read and understood. I have no reason to doubt the information sources.

Dennis, regarding the theory of the barrier coating, I can only pass on what I have read and understood. I have no reason to doubt the information sources.

Please Log in or Create an account to join the conversation.

- Dave Marles

- Offline

- Posts: 25

- Karma: 8

- Thank you received: 6

strictlybusiness1 replied the topic: Tiger King 27cc Engine Making Waves

Dave,

The following is typical of what I have read & found through testing in 30 cc size engines.

"I just finished reading the post on porting the underside of the piston. Some of the post mentioned the benefits of thermal barriers being used on the tops of the pistons. About 10 years ago a customer with deep pockets wanted me to develop a single cylinder engine for 250cc shifter kart. He was an older gentleman that used to drive top fuel dragsters. He was not too concerned about his driving abilities in the corners, he just wanted to pass people on the straight-aways. Initially we developed his CR 250 Honda engine on gasoline. We spent 2 or 3 months, went through a lot of cylinders, heads, carbs, ignitions, built around 30 completely different exhaust system with many head pipe and midsection adjustments on each system to get the desired shape of power curve. Our quest for more power continued until the piston crown reached its thermal limits. He petitioned the local club to let him run methanol. They agreed to let him run methanol with a slight weight penalty. He came back to me and now he wanted to develop the engine to run on methanol. We started over, developing new cylinders, heads, exhaust etc. We continued to develop the engine until we again reached the thermal limits of the piston crown. We pushed the power limits about 12 to 15 HP higher on methanol until we reached the same thermal limits of the piston crown.

We decided to try some insulating barriers applied to the piston crown. We sent off a batch of pistons to some place in New York. I think one of the barriers was almost undetectable as far as color and the other one was on off white to gray look. I made the necessary adjustment in the piston to head clearance to allow for the thickness of the coating and checked and set the clearance volumes to the same specs we had on the uncoated pistons. I think the thickness was about .002 to .003 in. thick.

We install one of the new pistons and continued our dyno testing on the engine. We had instant detonation problems as soon as the engine came up to temp under a sustained hard load. We made many adjustments to carburetion, ignition timing, different spark plug designs, combustion chamber designs, stinger diameter changes and any thing else I could think of that would help eliminate the detonation problem without throwing away the power we had worked so long for. I changed to the other piston. I think that one had the white to gray colored coating on the piston crown. The detonation problem was a little more severe. We put a stock uncoated piston back in the engine and the detonation problems immediately went away.

The under side of the coated pistons did not show any signs of overheating where the stock pistons that were operating on the thermal limits had stalactites of ash clinging to the bottom side of the piston. I went back to some of my thermodynamics text books and hand books on heat transfer and properties of good insulators and did a quick study: some of the characteristic themes of a good insulator was… 1) very little energy is transferred through the insulator….2) the surface temperature of the insulator on the heat source side of the insulator is very close to the same temperature as the heat source. 3) The temperature on the other side of the insulator is very close to the temperature of the medium or heat sink.

I came to the conclusion that the thermal barrier was reducing heat transfer into the piston crown. ( I think the underside of the piston reinforced this conclusion) I also believe the surface temperatures of the coating was so high that it was promoting the detonation, even though the piston crown was much cooler than the uncoated pistons crowns that did not promote detonation.

I am sure I am not the first engine developer to encounter the problem. The coating people did not have any explanations. Some of my associates are engineers for some of the aerospace companies that coat all kinds of parts in the high heat side of the gas turbines and jet engines. They say the coatings helps reduce the heat input into the hot parts of the engine, but they do not have to deal with detonation problem that plague high output piston engines. Do these coatings really benefit a piston engine that is developed to the point that the whole top of the piston is on the verge of caving in because of the high thermal load? Should we coat the top of the pistons to help prevent the piston crown from caving in and have the detonation eat up the outer edges of the piston, head and cylinder? Should we run the uncoated pistons that were detonation free but the tops occasionally sag or crack? I welcome your input. What was I missing?"

All I'm asking is why TK found it necessary to coat the piston crowns?

Jim Allen

The following is typical of what I have read & found through testing in 30 cc size engines.

"I just finished reading the post on porting the underside of the piston. Some of the post mentioned the benefits of thermal barriers being used on the tops of the pistons. About 10 years ago a customer with deep pockets wanted me to develop a single cylinder engine for 250cc shifter kart. He was an older gentleman that used to drive top fuel dragsters. He was not too concerned about his driving abilities in the corners, he just wanted to pass people on the straight-aways. Initially we developed his CR 250 Honda engine on gasoline. We spent 2 or 3 months, went through a lot of cylinders, heads, carbs, ignitions, built around 30 completely different exhaust system with many head pipe and midsection adjustments on each system to get the desired shape of power curve. Our quest for more power continued until the piston crown reached its thermal limits. He petitioned the local club to let him run methanol. They agreed to let him run methanol with a slight weight penalty. He came back to me and now he wanted to develop the engine to run on methanol. We started over, developing new cylinders, heads, exhaust etc. We continued to develop the engine until we again reached the thermal limits of the piston crown. We pushed the power limits about 12 to 15 HP higher on methanol until we reached the same thermal limits of the piston crown.

We decided to try some insulating barriers applied to the piston crown. We sent off a batch of pistons to some place in New York. I think one of the barriers was almost undetectable as far as color and the other one was on off white to gray look. I made the necessary adjustment in the piston to head clearance to allow for the thickness of the coating and checked and set the clearance volumes to the same specs we had on the uncoated pistons. I think the thickness was about .002 to .003 in. thick.

We install one of the new pistons and continued our dyno testing on the engine. We had instant detonation problems as soon as the engine came up to temp under a sustained hard load. We made many adjustments to carburetion, ignition timing, different spark plug designs, combustion chamber designs, stinger diameter changes and any thing else I could think of that would help eliminate the detonation problem without throwing away the power we had worked so long for. I changed to the other piston. I think that one had the white to gray colored coating on the piston crown. The detonation problem was a little more severe. We put a stock uncoated piston back in the engine and the detonation problems immediately went away.

The under side of the coated pistons did not show any signs of overheating where the stock pistons that were operating on the thermal limits had stalactites of ash clinging to the bottom side of the piston. I went back to some of my thermodynamics text books and hand books on heat transfer and properties of good insulators and did a quick study: some of the characteristic themes of a good insulator was… 1) very little energy is transferred through the insulator….2) the surface temperature of the insulator on the heat source side of the insulator is very close to the same temperature as the heat source. 3) The temperature on the other side of the insulator is very close to the temperature of the medium or heat sink.

I came to the conclusion that the thermal barrier was reducing heat transfer into the piston crown. ( I think the underside of the piston reinforced this conclusion) I also believe the surface temperatures of the coating was so high that it was promoting the detonation, even though the piston crown was much cooler than the uncoated pistons crowns that did not promote detonation.

I am sure I am not the first engine developer to encounter the problem. The coating people did not have any explanations. Some of my associates are engineers for some of the aerospace companies that coat all kinds of parts in the high heat side of the gas turbines and jet engines. They say the coatings helps reduce the heat input into the hot parts of the engine, but they do not have to deal with detonation problem that plague high output piston engines. Do these coatings really benefit a piston engine that is developed to the point that the whole top of the piston is on the verge of caving in because of the high thermal load? Should we coat the top of the pistons to help prevent the piston crown from caving in and have the detonation eat up the outer edges of the piston, head and cylinder? Should we run the uncoated pistons that were detonation free but the tops occasionally sag or crack? I welcome your input. What was I missing?"

All I'm asking is why TK found it necessary to coat the piston crowns?

Jim Allen

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

strictlybusiness1 replied the topic: Tiger King 27cc Engine Making Waves

Last edit: 11 years 11 months ago by strictlybusiness1.

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

strictlybusiness1 replied the topic: Tiger King 27cc Engine Making Waves

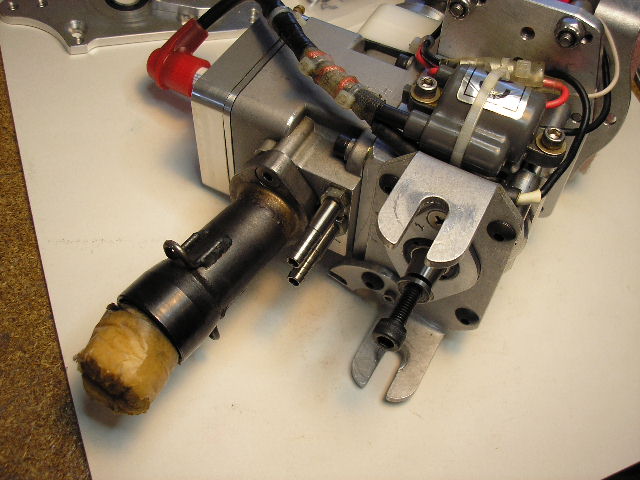

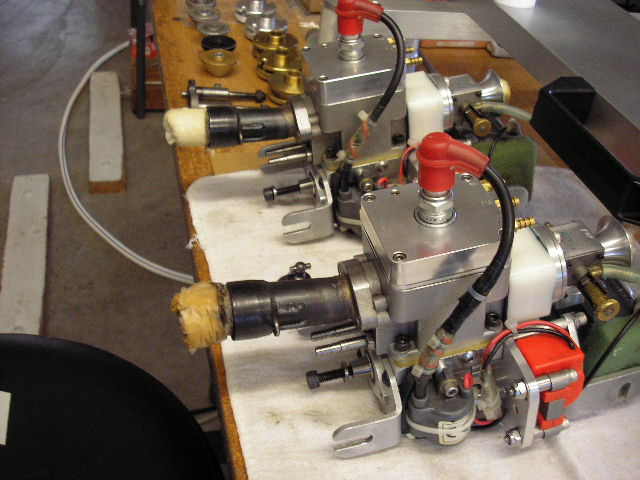

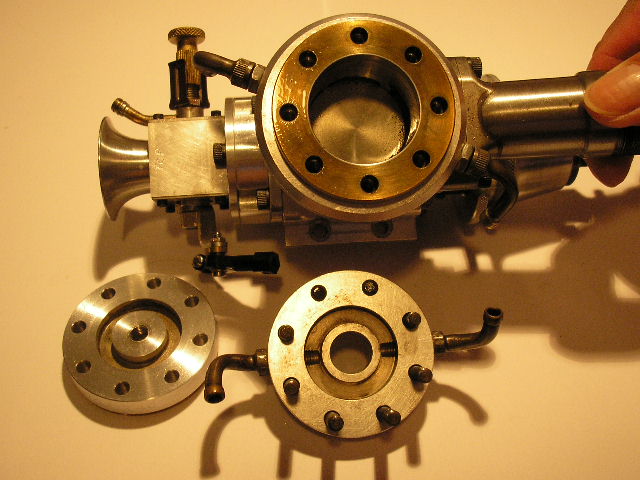

You can usually improve on what is OEM stuff, but this is not always possible. Poor initial design of any part in a high output two cycle engine can sometimes make it impossible to fix without a great deal of work. For example, one of the poorest designed areas, in the engine being discussed, is the placement of the head bolts outside of the major diameter of the sleeves lip & the head button. A much better design that is being used in large size as well as very small size high performance miniature engines is to place the bolts through the head button & through the liners lip into the solid part of the case. Examples of this can be found in OD's, Nelson .45 long stroke pylon racing engines, John Faulk's record setting tether car engines & My 15 cc engine. In the examples given not only do the heads bolts go through the liners lip & the head button, but there are a large number of bolts placed close to one another to insure very even tightening of the head button. A thick, large diameter lip in this area stabilizes the cylinder's upper area, keeping it round, where the most force & heat is concentrated. It also greatly improves upper cylinder cooling. Other small engine builders may have discovered this very important design feature.

Jim Allen

Jim Allen

Attachment 625borebarrelcarburetoronQD050.jpg not found

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Hot Rods replied the topic: Tiger King 27cc Engine Making Waves

It has been advertised by TK that they have ( or will have ) different buttons to raise the compression ratio beyond standard. The coating may be insurance for down the road ( piston crown damage ), but given that these engines are now fairly low compression, rope started units, I would suspect the coating to be more of a selling ploy than anything really nessesary at this time. On the other hand, maybe the lower crown temps reduce the chances of upper piston expansion and seizures.

Please Log in or Create an account to join the conversation.

- Hot Rods

-

- Offline

- Posts: 164

- Karma: -5

- Thank you received: 36

Dave Marles replied the topic: Tiger King 27cc Engine Making Waves

Jim, I only added my replies to this thread to provide answers to questions being asked about the TK engine because I actually had one and had run it hard for some time.. You have to forgive me if I tell you that I do not want to hijack this into a discussion about best cooling practice on other engines.

Jim, regarding the ceramic coatings: I recommend reading everything up to the end of 2005 in the thread "Thermal coatings on piston crowns" on the two stroke tech site. Extremely interesting particularly that it shows that head and pipe design etc could not be the same for uncoated and coated pistons.

Dave

Jim, regarding the ceramic coatings: I recommend reading everything up to the end of 2005 in the thread "Thermal coatings on piston crowns" on the two stroke tech site. Extremely interesting particularly that it shows that head and pipe design etc could not be the same for uncoated and coated pistons.

Dave

The following user(s) said Thank You: strictlybusiness1

Please Log in or Create an account to join the conversation.

- Dave Marles

- Offline

- Posts: 25

- Karma: 8

- Thank you received: 6

whitefish replied the topic: Tiger King 27cc Engine Making Waves

JA wrote:

>The quickest & cheapest way to tell if the sleeve is iron or steel is with a spark test

>in a slightly lighted room. There is a great deal of information on the internet with

>videos of what to look for when comparing iron to steel. With that said, I'm fairly sure

>the sleeve is not iron. This would work, even with the ductile iron ring. However, it's

>life would be very short at the RPM's we run at without the use of an oil ring.

I saw those videos on-line and did not know if it was a legit shop practice or not. Based

on your confirmation, I will have a go at it and see (pun) if I can develop some skills

with that method.

and JA wrote:

>All I'm asking is why TK found it necessary to coat the piston crowns?

Another interesting question is has TK found a way to have the coated piston crown and

made some other mod that has helped with controlling detonation? No other purpose built

marine engine has ever shipped with a thermal barrier piston.

What we do know is they have chosen a thicker iron sleeve and now there is mention of

a button assortment for changing compression.

- the thicker iron sleeve is going to have some heat adsorption and dissipation

characteristics that cannot be overlooked. it also may be acting like a larger

combustion chamber heatsink

- this iron sleeve with greater mass is fitted to an aluminum cylinder with an integral

waterjacket that works with the cooling cap.

I'm suspecting TK has done some R&D resulting in a slightly different approach to heat

adsorption and dissipation.

>The quickest & cheapest way to tell if the sleeve is iron or steel is with a spark test

>in a slightly lighted room. There is a great deal of information on the internet with

>videos of what to look for when comparing iron to steel. With that said, I'm fairly sure

>the sleeve is not iron. This would work, even with the ductile iron ring. However, it's

>life would be very short at the RPM's we run at without the use of an oil ring.

I saw those videos on-line and did not know if it was a legit shop practice or not. Based

on your confirmation, I will have a go at it and see (pun) if I can develop some skills

with that method.

and JA wrote:

>All I'm asking is why TK found it necessary to coat the piston crowns?

Another interesting question is has TK found a way to have the coated piston crown and

made some other mod that has helped with controlling detonation? No other purpose built

marine engine has ever shipped with a thermal barrier piston.

What we do know is they have chosen a thicker iron sleeve and now there is mention of

a button assortment for changing compression.

- the thicker iron sleeve is going to have some heat adsorption and dissipation

characteristics that cannot be overlooked. it also may be acting like a larger

combustion chamber heatsink

- this iron sleeve with greater mass is fitted to an aluminum cylinder with an integral

waterjacket that works with the cooling cap.

I'm suspecting TK has done some R&D resulting in a slightly different approach to heat

adsorption and dissipation.

The following user(s) said Thank You: strictlybusiness1

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

strictlybusiness1 replied the topic: Tiger King 27cc Engine Making Waves

I read the entire thing several times as well as the other posted information about coatings. I also read about how changes to the pipe's shape, stinger length & diameter, compression, jetting, etc. would be necessary for running this stuff. Do you think TK has developed a tuned pipe dedicated to the coated piston? One thing is for sure, there is no one type tuned pipe that will fit every tuning situation on any engine!

This has been a excellent discussion. I hope the TK manufacturers read it carefully!

Jim

This has been a excellent discussion. I hope the TK manufacturers read it carefully!

Jim

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Time to create page: 0.246 seconds