Evidence Of Excessive Heat

whitefish created the topic: Evidence Of Excessive Heat

Over in the "piston pin spacer's help" thread, I noted the wrist pin bearing end

gap on a CY F273 that I described as having been overheated numerous times (not

the engines fault - completely my bad). The 0.014 inch reading was questioned by

JA (rightly so, I'm sure) so since I was doing a teardown inspection anyway, I

finally got the piston removed and had a surprise in store for me.

The wrist pin no longer floats in the piston bore. Was not seized but would

only remove by being tapped lightly. Yuck! The visual evidence of heat damage

is easy to see.

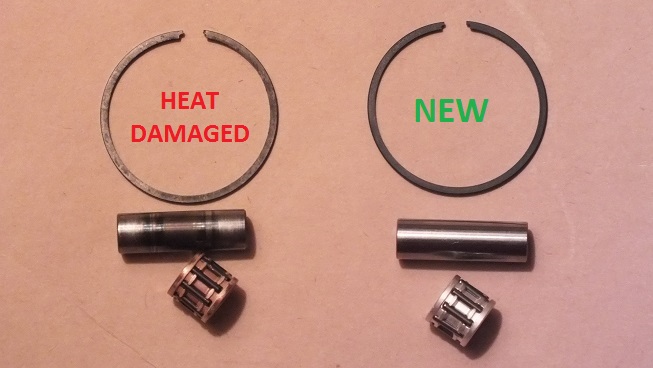

In the pic CY F273 HEAT DAMAGE 1, the blue mark in the center of the wrist pin

is the reason the pin no longer floats in the piston bore. Also interesting to

note the color change of the wrist pin bearing. What was once silver (like the

new bearings on the right) has now changed to a bronze color.

While there is some color change in the damaged ring, there is also two other

changes with the same ring that may be worth mentioning.

1. - the ring is now slightly warped from heat

2. - when removing the ring from it's piston, the effort required to get it off is

noticeably less than before the heat events

Might be more accurate to describe the ring damage as saying one of the two tips

is now sprung outward. I know the gaps look very similar in that one pic but the

damaged ring and the new ring require very different amounts of pressure be applied

when installing or removing them from the piston. The temper of the ring's metal

has probably been altered as well.

Comparing the top of the con rod with a new one indicates it was not damaged. A new

piston kit should get things going again. Checking the end gap on the wrist pin and

washers shows a reduction from 0.014 inch to 0.012 inch with the new piston kit

installed. The 0.002 inch difference was a little less than I expected.

I should repeat that this is not a "My CY Overheated And I Don't Know Why" thread.

The heat events happened because I was trying modifications to the coolant flow

system and some of the ideas I tried resulted in insufficient coolant - risky

behavior but still fun none the less.

Question: If heat damage effects the top of the con rod, will the rod change

color too or is measuring the rod's bore the only way to detect changes?

gap on a CY F273 that I described as having been overheated numerous times (not

the engines fault - completely my bad). The 0.014 inch reading was questioned by

JA (rightly so, I'm sure) so since I was doing a teardown inspection anyway, I

finally got the piston removed and had a surprise in store for me.

The wrist pin no longer floats in the piston bore. Was not seized but would

only remove by being tapped lightly. Yuck! The visual evidence of heat damage

is easy to see.

In the pic CY F273 HEAT DAMAGE 1, the blue mark in the center of the wrist pin

is the reason the pin no longer floats in the piston bore. Also interesting to

note the color change of the wrist pin bearing. What was once silver (like the

new bearings on the right) has now changed to a bronze color.

While there is some color change in the damaged ring, there is also two other

changes with the same ring that may be worth mentioning.

1. - the ring is now slightly warped from heat

2. - when removing the ring from it's piston, the effort required to get it off is

noticeably less than before the heat events

Might be more accurate to describe the ring damage as saying one of the two tips

is now sprung outward. I know the gaps look very similar in that one pic but the

damaged ring and the new ring require very different amounts of pressure be applied

when installing or removing them from the piston. The temper of the ring's metal

has probably been altered as well.

Comparing the top of the con rod with a new one indicates it was not damaged. A new

piston kit should get things going again. Checking the end gap on the wrist pin and

washers shows a reduction from 0.014 inch to 0.012 inch with the new piston kit

installed. The 0.002 inch difference was a little less than I expected.

I should repeat that this is not a "My CY Overheated And I Don't Know Why" thread.

The heat events happened because I was trying modifications to the coolant flow

system and some of the ideas I tried resulted in insufficient coolant - risky

behavior but still fun none the less.

Question: If heat damage effects the top of the con rod, will the rod change

color too or is measuring the rod's bore the only way to detect changes?

Last edit: 12 years 6 months ago by whitefish.

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

Canadian Hot Rod RC Boats replied the topic: Evidence Of Excessive Heat

I have seen some with discoloration - but I believe the stock Sikk 27 cc is not - so I (personally) would be leary of reusing that particular crank ..... JM2C

www.davesmotors.com/dd336

Cheers

DDM has a kit on sale for that engine for 85 dollars

www.davesmotors.com/s.nl/it.A/id.5523/.f

www.davesmotors.com/dd336

Cheers

DDM has a kit on sale for that engine for 85 dollars

www.davesmotors.com/s.nl/it.A/id.5523/.f

Zoom Zoom .....

Toy Boats Toy Boats

Misty Creek Boats

www.youtube.com/channel/UCjwPZIU4nBUUk1CG0xf3TnQ

Please Log in or Create an account to join the conversation.

- Canadian Hot Rod RC Boats

-

- Offline

- Posts: 959

- Karma: 12

- Thank you received: 68

strictlybusiness1 replied the topic: Evidence Of Excessive Heat

Mr. CC,

I have been receiving e-mails from some Australian model boaters about having heating problems with upper end roller assemblies in Zenoah 2 mm stroker crank assemblies. They solved the problems by removing the upper end retainer, adding ten more rollers & machining new thrust washers to reduce the axial clearance down to .005" to .007". They said the new spacers were hardened to 61 Rc. The next step will be to replace the standard hollow wrist pins with a wrist pin that is solid in the middle & drilled from both ends. Any slight flexing of the wrist pin can cause problems such as the one you show as well as the wrist pin hole becoming egg shaped.

New wrist pins & rollers will be made from M-2 or M-42 pre-hardened, precision pre-ground blanks available from William T. Hutchinson. These two high speed steel materials have very high heat capabilities (1000* F) without becoming soft & have very high wear resistance. The blanks are 6" long & can be easily cut with a Dremel abrasive wheel.

There are other solutions to this problem that involve more than replacing the parts until it happens again.

Jim Allen

I have been receiving e-mails from some Australian model boaters about having heating problems with upper end roller assemblies in Zenoah 2 mm stroker crank assemblies. They solved the problems by removing the upper end retainer, adding ten more rollers & machining new thrust washers to reduce the axial clearance down to .005" to .007". They said the new spacers were hardened to 61 Rc. The next step will be to replace the standard hollow wrist pins with a wrist pin that is solid in the middle & drilled from both ends. Any slight flexing of the wrist pin can cause problems such as the one you show as well as the wrist pin hole becoming egg shaped.

New wrist pins & rollers will be made from M-2 or M-42 pre-hardened, precision pre-ground blanks available from William T. Hutchinson. These two high speed steel materials have very high heat capabilities (1000* F) without becoming soft & have very high wear resistance. The blanks are 6" long & can be easily cut with a Dremel abrasive wheel.

There are other solutions to this problem that involve more than replacing the parts until it happens again.

Jim Allen

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

whitefish replied the topic: Evidence Of Excessive Heat

JA:

Thanks for describing those improved parts. When I can find the time, I would really enjoy

learning how to make and use components like you suggest. You don't happen to remember

which part numbers from W.T. Hutchinson those Aussie's are using or know where I could

see pics of the parts they are making?

Please remember to place the blame for my heat events where they belong - squarely

on me. I almost did not post those pics for fear I would spark another "CY Sucks So Bad"

rant - I'm so not interested in that. I get good value from CY engines and parts - with DDM

just on the other side of the Rockies, I would be nuts not to rely on their amazing

inventory. This is not to imply "CY Is The Greatest" or any foolishness like that - but when

I do have to pitch some parts, the cost is reasonable and that helps keep the wife off my

back about the price of my toys.

mr. whitefish

Thanks for describing those improved parts. When I can find the time, I would really enjoy

learning how to make and use components like you suggest. You don't happen to remember

which part numbers from W.T. Hutchinson those Aussie's are using or know where I could

see pics of the parts they are making?

Please remember to place the blame for my heat events where they belong - squarely

on me. I almost did not post those pics for fear I would spark another "CY Sucks So Bad"

rant - I'm so not interested in that. I get good value from CY engines and parts - with DDM

just on the other side of the Rockies, I would be nuts not to rely on their amazing

inventory. This is not to imply "CY Is The Greatest" or any foolishness like that - but when

I do have to pitch some parts, the cost is reasonable and that helps keep the wife off my

back about the price of my toys.

mr. whitefish

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

strictlybusiness1 replied the topic: Evidence Of Excessive Heat

CC,

I also correspond with some south African boaters who are twisting the same 2 mm stroker crankshafts I referred too. They say the crankshafts are twisting without dunking the boats. They are replacing the crankpins, wrist pins & rollers with either M-2 or M-42, HSS, pre-hardened, pre precision ground blanks. Since the blanks come ready to use, they only require cutting with any abrasive type wheel to the correct length & rounding & polishing the cut ends. They are available from William T. Hutchinson Co. & there is no minimum amount to be purchased. As an example, I usually purchase 6" long blanks, typically $20.00+ dollars, which will make approximately 6 crank pins.

There are no part numbers for the blanks. The only information that is necessary is the size of the blank to four decimal places. Some times I order blanks that are plus or minus .0002" from the nominal size. For example, a wrist pin is 8 mm (.3150"). I purchase .3150" minus .0002" (.3148") for wrist pins. 1.5 mm rollers are replaced with .0591" plus or minus .0000" pins. The wrist pins are drilled from both ends but left solid in the middle for rigidity & reduced weight. Crank pins are .3940" plus .0002" which means the press fit amount is increased .0005" above the stock crank pin of .3937" (10 mm). NO REGRINDING OF ANY STOCK ROD"S BOTTOM END ID WILL BE NECESSARY TO USE THE LARGER SIZE .3942" CRANK PIN. These people made their own assembly fixture & understand the process required to true the crankshaft.

The other solutions I referred to involve a .3950" minus .0002" (.3948") size crank pin. This increases the press fit amount .0011", but requires re-grinding of the connecting rod's bottom hole ID. Both crank pin modifications can use the stock 9 roller assembly with it's steel retainer. In my assemblies, I use a full hard (Rc-60), precision machined retainer that carries 16 rollers. Increasing the roller count does not reduce the assemblies maximum rotating speed, but it does increase it's ability to carry a much greater load. The wear resistance of the roller assembly is also greatly increased.

JA

I also correspond with some south African boaters who are twisting the same 2 mm stroker crankshafts I referred too. They say the crankshafts are twisting without dunking the boats. They are replacing the crankpins, wrist pins & rollers with either M-2 or M-42, HSS, pre-hardened, pre precision ground blanks. Since the blanks come ready to use, they only require cutting with any abrasive type wheel to the correct length & rounding & polishing the cut ends. They are available from William T. Hutchinson Co. & there is no minimum amount to be purchased. As an example, I usually purchase 6" long blanks, typically $20.00+ dollars, which will make approximately 6 crank pins.

There are no part numbers for the blanks. The only information that is necessary is the size of the blank to four decimal places. Some times I order blanks that are plus or minus .0002" from the nominal size. For example, a wrist pin is 8 mm (.3150"). I purchase .3150" minus .0002" (.3148") for wrist pins. 1.5 mm rollers are replaced with .0591" plus or minus .0000" pins. The wrist pins are drilled from both ends but left solid in the middle for rigidity & reduced weight. Crank pins are .3940" plus .0002" which means the press fit amount is increased .0005" above the stock crank pin of .3937" (10 mm). NO REGRINDING OF ANY STOCK ROD"S BOTTOM END ID WILL BE NECESSARY TO USE THE LARGER SIZE .3942" CRANK PIN. These people made their own assembly fixture & understand the process required to true the crankshaft.

The other solutions I referred to involve a .3950" minus .0002" (.3948") size crank pin. This increases the press fit amount .0011", but requires re-grinding of the connecting rod's bottom hole ID. Both crank pin modifications can use the stock 9 roller assembly with it's steel retainer. In my assemblies, I use a full hard (Rc-60), precision machined retainer that carries 16 rollers. Increasing the roller count does not reduce the assemblies maximum rotating speed, but it does increase it's ability to carry a much greater load. The wear resistance of the roller assembly is also greatly increased.

JA

Last edit: 12 years 6 months ago by strictlybusiness1. Reason: add information

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Time to create page: 0.071 seconds