Port Timing and Squish

manyhobbies created the topic: Port Timing and Squish

This thread discusses the Content article:

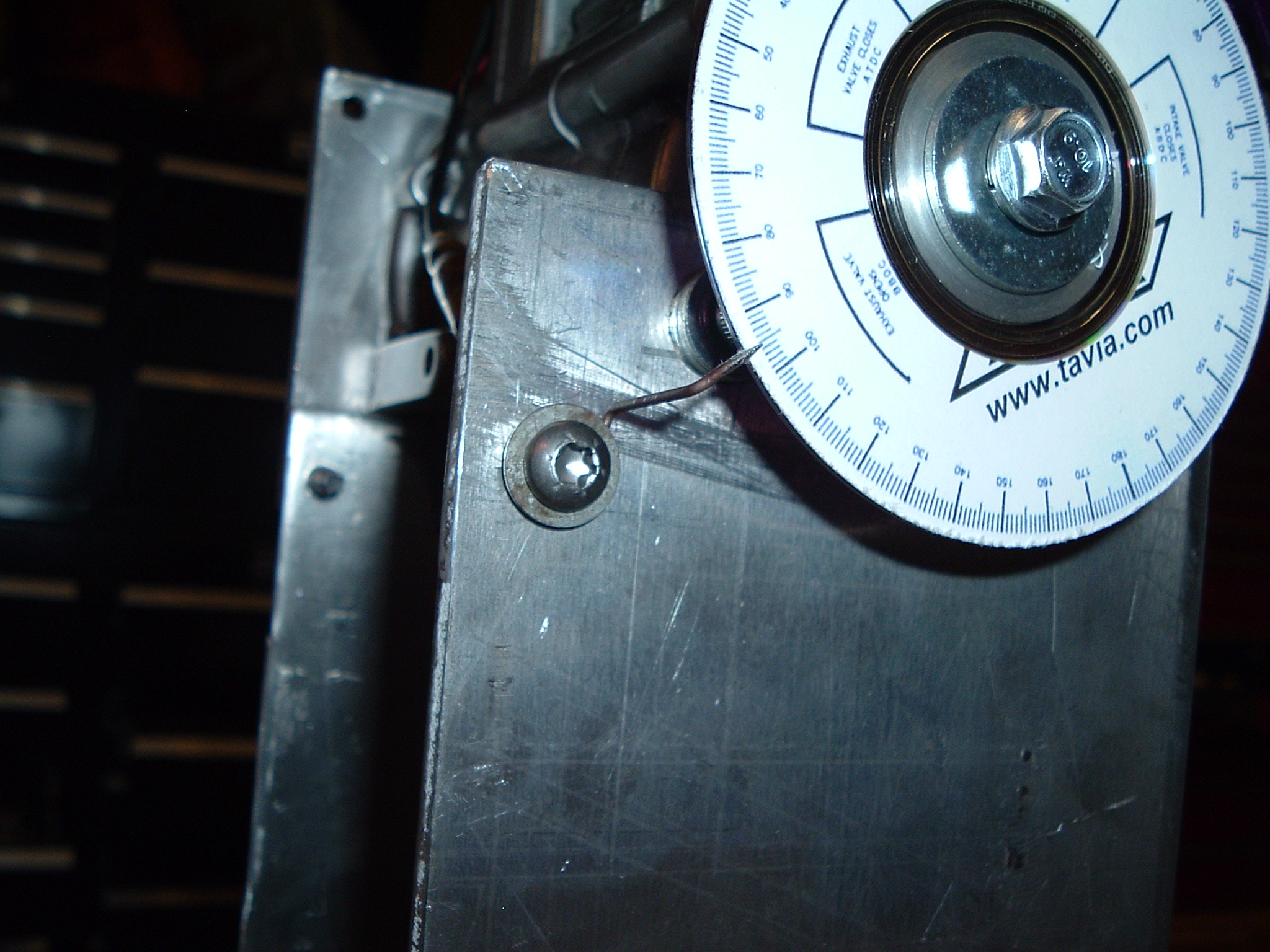

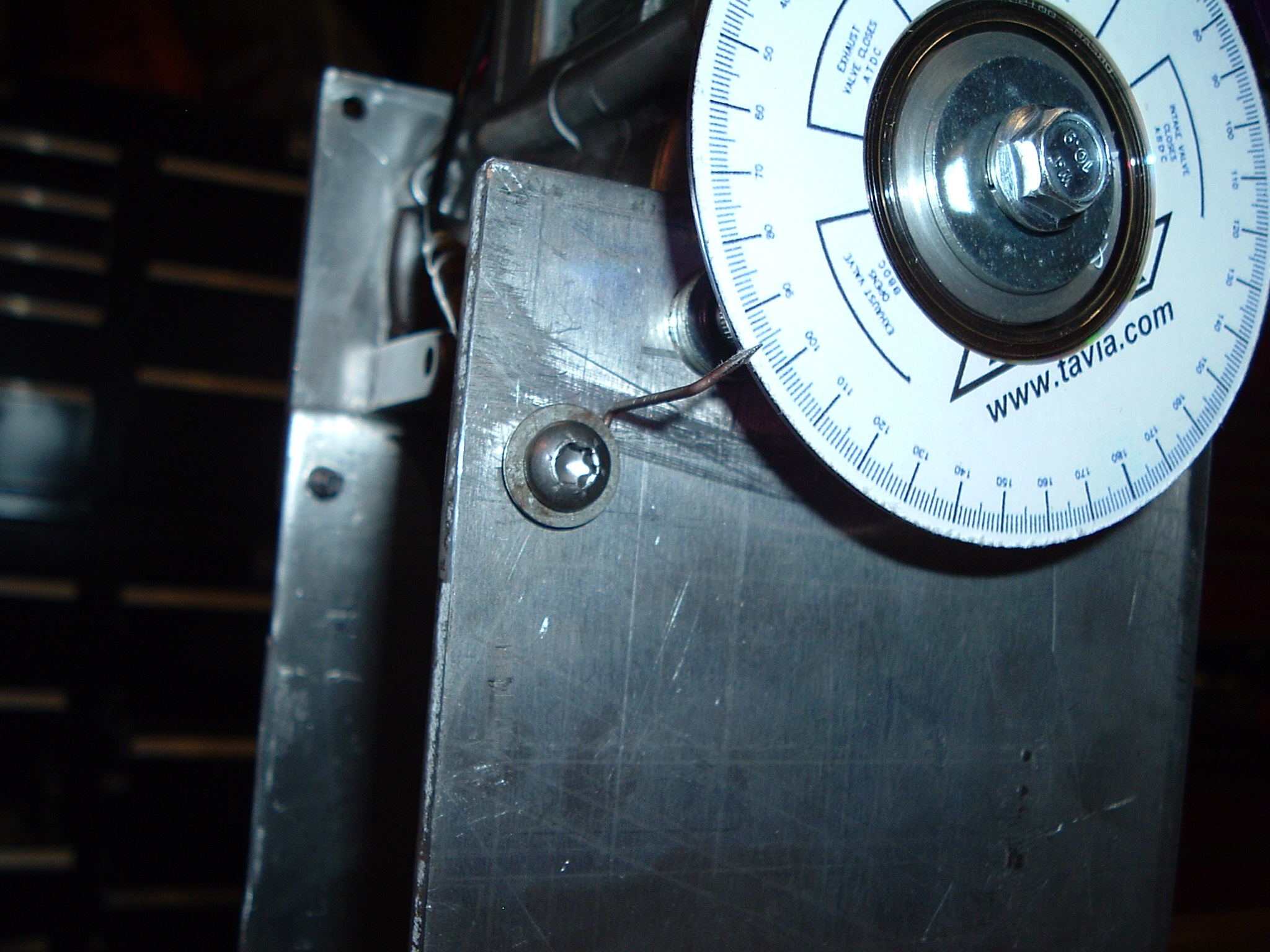

Port Timing and Squish

Marc, good write up. But you left out how to accomplish top dead center on the wheel. Without a accurate top dead center the wheel isnt much help, so the viewers need to know how to accomplish that so there is a true zero point to reference.

Marc, good write up. But you left out how to accomplish top dead center on the wheel. Without a accurate top dead center the wheel isnt much help, so the viewers need to know how to accomplish that so there is a true zero point to reference.

Second place is the first loser.

Last edit: 17 years 2 months ago by marc.

Please Log in or Create an account to join the conversation.

- manyhobbies

- Offline

- Posts: 36

- Thank you received: 0

marc replied the topic: Re:Port Timing and Squish

There is no need to find TDC to measure port duration. That's why I left it out and also mentioned in the article that I wouldn't explain how to zero the wheel or make it any more complicated than it needs to be. If you read the steps again and understand them (the way I am doing it), you will know why I am saying this.

Ex duration is from moment of open-start to moment of complete-close, going through BDC.

Int. duration is from moment of open-start to moment of complet-close, going through TDC.

There is no justifiable need to find the actual TDC or BDC for the purpose of measuring the port duration measuring this way. In addition it is more accurate in my opinion. No doubling or halving, and you also take into account the "slop" in the connecting rod at TDC and BDC.

*** there is nothing wrong however with zeroing your wheel at TDC for ease of measuring, and common practice is to do so.

Ex duration is from moment of open-start to moment of complete-close, going through BDC.

Int. duration is from moment of open-start to moment of complet-close, going through TDC.

There is no justifiable need to find the actual TDC or BDC for the purpose of measuring the port duration measuring this way. In addition it is more accurate in my opinion. No doubling or halving, and you also take into account the "slop" in the connecting rod at TDC and BDC.

*** there is nothing wrong however with zeroing your wheel at TDC for ease of measuring, and common practice is to do so.

"

Last edit: 17 years 2 months ago by marc.

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

marc replied the topic: Re:Port Timing and Squish

I have added the info on how to Zero the wheel in the article. Thank you for the suggestion.

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

manyhobbies replied the topic: Re:Port Timing and Squish

Thanks Marc for editing this. One thing to note to anyone zeroing a degree wheel, only use a piston stop as thats the only accurate way to get to zero. Using a indicator through the spark plug will not be accurate as there is a what is called a teetering point where the crank will rotate in either direction a couple degree's but the piston won't move to reflect this.

As Marc mentioned to me and I do agree, this step is not important if you are only measuring the timing. However, if you plan to cut on the engine make sure the wheel does'nt move on the crank so it can easily be used to recheck your timing afterwards.

The only importance to zeroing is so you can reference all your begining and ending points to a degree before and after TDC,BDC, this allows you to log the BTDC, ATDC, BBDC, ABDC. These points will show duration between ports, timing duration etc etc. It's good common practice to learn and understand the effects of timing duration.

If someone were to ask you at what degree ATDC does the exaust port open on your self modded engine you could give them a true answere, or at what degree ABDC the intake port opens, you could give a true answere, but if you don't zero the degree wheel you would have to do a lot of unneeded math.

It is true that much of this info is unneeded, but any professional engine builder should be able to tell you these answere's if asked as this is important info when it comes to making power and 1 of the variables to keeping it consistant. Marc, I think it would be awesome if you could show the readers all these timing points.

I am such a pain arent I Marc lol. RUSS

As Marc mentioned to me and I do agree, this step is not important if you are only measuring the timing. However, if you plan to cut on the engine make sure the wheel does'nt move on the crank so it can easily be used to recheck your timing afterwards.

The only importance to zeroing is so you can reference all your begining and ending points to a degree before and after TDC,BDC, this allows you to log the BTDC, ATDC, BBDC, ABDC. These points will show duration between ports, timing duration etc etc. It's good common practice to learn and understand the effects of timing duration.

If someone were to ask you at what degree ATDC does the exaust port open on your self modded engine you could give them a true answere, or at what degree ABDC the intake port opens, you could give a true answere, but if you don't zero the degree wheel you would have to do a lot of unneeded math.

It is true that much of this info is unneeded, but any professional engine builder should be able to tell you these answere's if asked as this is important info when it comes to making power and 1 of the variables to keeping it consistant. Marc, I think it would be awesome if you could show the readers all these timing points.

I am such a pain arent I Marc lol. RUSS

Second place is the first loser.

Please Log in or Create an account to join the conversation.

- manyhobbies

- Offline

- Posts: 36

- Thank you received: 0

Ed Sidders replied the topic: Re:Port Timing and Squish

Over the years of building race engines I came up with a system that worked very well. I made a degree wheel printout on fairly heavy paper and attached it over a standard degree wheel. On this paper I marked 3 deg before and after TDC so that 1/2 way between is actual TDC. this was located using a piston stop.I also noted port open and close points . That was very helpful when a customer called and needed spec's on his engine.Blue magic marker on the intake and red on the exhaust makes a real graphic demonstration of intake and exhaust timing and overlap.Each engine I built has one of these in my file cabinet

Please Log in or Create an account to join the conversation.

- Ed Sidders

- Offline

- Posts: 86

- Thank you received: 0

manyhobbies replied the topic: Re:Port Timing and Squish

Ed Sidders wrote:This is why I feel it is important to zero the degree wheel when setting it up. I am aware that the actual checking of and changing of the port timings is irrelevent to zero'ing the wheel, but like you mentioned Ed, it allows you to know every aspect of the timing of the engine, and yes, even overlap which I neglected to mention.

This was a good topic Marc and I know people will find all this info helpful.

RUSS

This was a good topic Marc and I know people will find all this info helpful.

RUSS

Second place is the first loser.

Please Log in or Create an account to join the conversation.

- manyhobbies

- Offline

- Posts: 36

- Thank you received: 0

marc replied the topic: Re:Port Timing and Squish

I am glad you guys are participating, that's what makes it better...I also agree that a lot of people can benefit from this information.

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Steve Seebold replied the topic: Re:Port Timing and Squish

Good write up marc. I whold think though you would want to zero the degree wheel ay zero when the port whether exhaust or intake at a point where said port opens. I think that would give you the most accurate measurement.

Remember though, opinions are like arm pits. Everyone has one and they all stink.

Remember though, opinions are like arm pits. Everyone has one and they all stink.

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

marc replied the topic: Re:Port Timing and Squish

The correct way of zeroing the wheel is at TDC, but you can do it differently if it suits you better. As long as you follow the steps and do them correctly you will get the results you need.

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Time to create page: 0.085 seconds