Name this boat??? And cooling help.....

LCYrace replied the topic: Re: Name this boat??? And cooling help.....

Thanks Larry for taking the time to reply. After searching for that model I can see for sure it is an old Dumas hull. Glad to finally know what to tell people when they ask about it. Hopefully get to try my new water pickup this weekend.

When in doubt, Gas it!

Please Log in or Create an account to join the conversation.

- LCYrace

- Offline

315neil1007 replied the topic: Re: Name this boat??? And cooling help.....

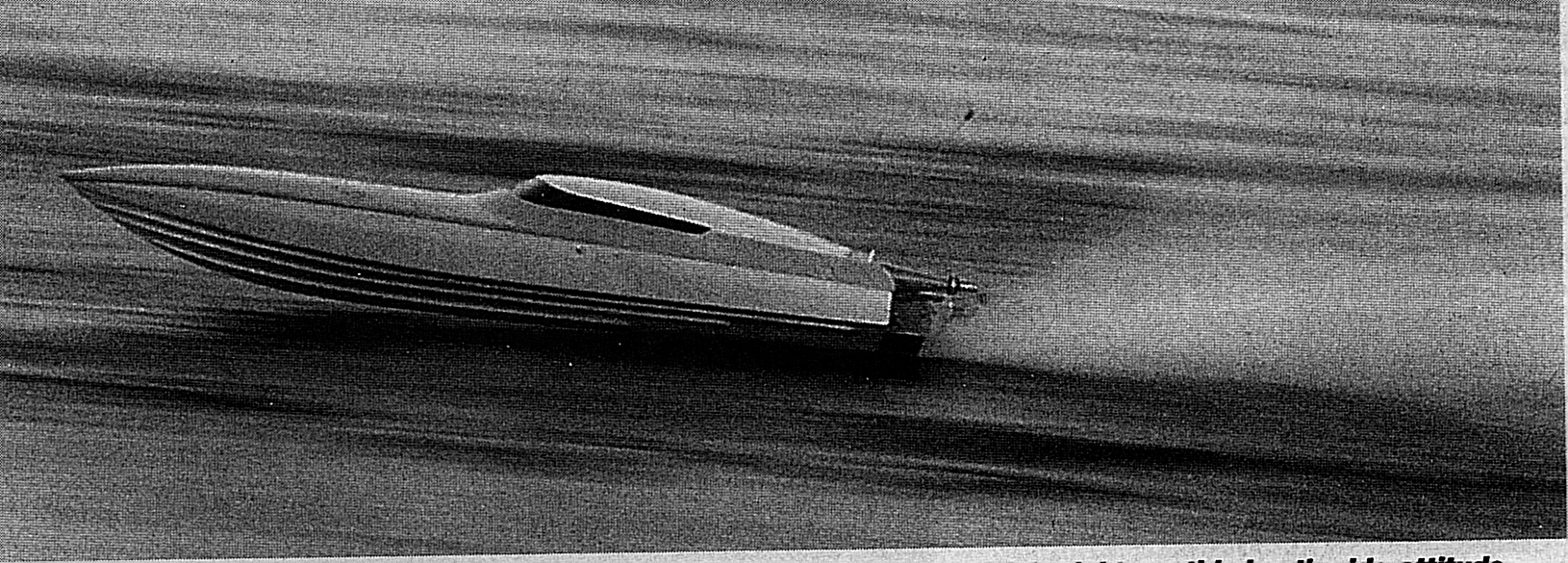

I picked up a hull from my LHS. The hull setup was way off. So I gutted the hull and rebuilt from the inside out.I added my Zenhoa from my Easy Vee. The whole radio box was replaced. I kept the original stinger strut. The old rudder was cut off very short. I new Zippkits rudder /hardware. We finally got to see her run,last week. I didn't add the right turn fin/ spin fin. Joe was in the hospital so I didn't get a spin fin. She ran great down the straightaway.The hull didn't turn very well or over turned. When we did the setup on the trim tabs. We turned the boat over got out a straight edge ruler and made all level. Launch the boat Look at the attitude.Bring back in turn down 1 full turn -launch -look and so on. If the hull leans more to one side, turn down that side on the trim tabs. Strut AoA will be even with the bottom of the hull. You use that to bring up the nose of the hull or down. This is what you want to see your hull ride look like. Lets see a pic of the inside So we can CK out.

Please Log in or Create an account to join the conversation.

- 315neil1007

-

- Offline

- Posts: 89

- Karma: 1

- Thank you received: 3

LCYrace replied the topic: Re: Name this boat??? And cooling help.....

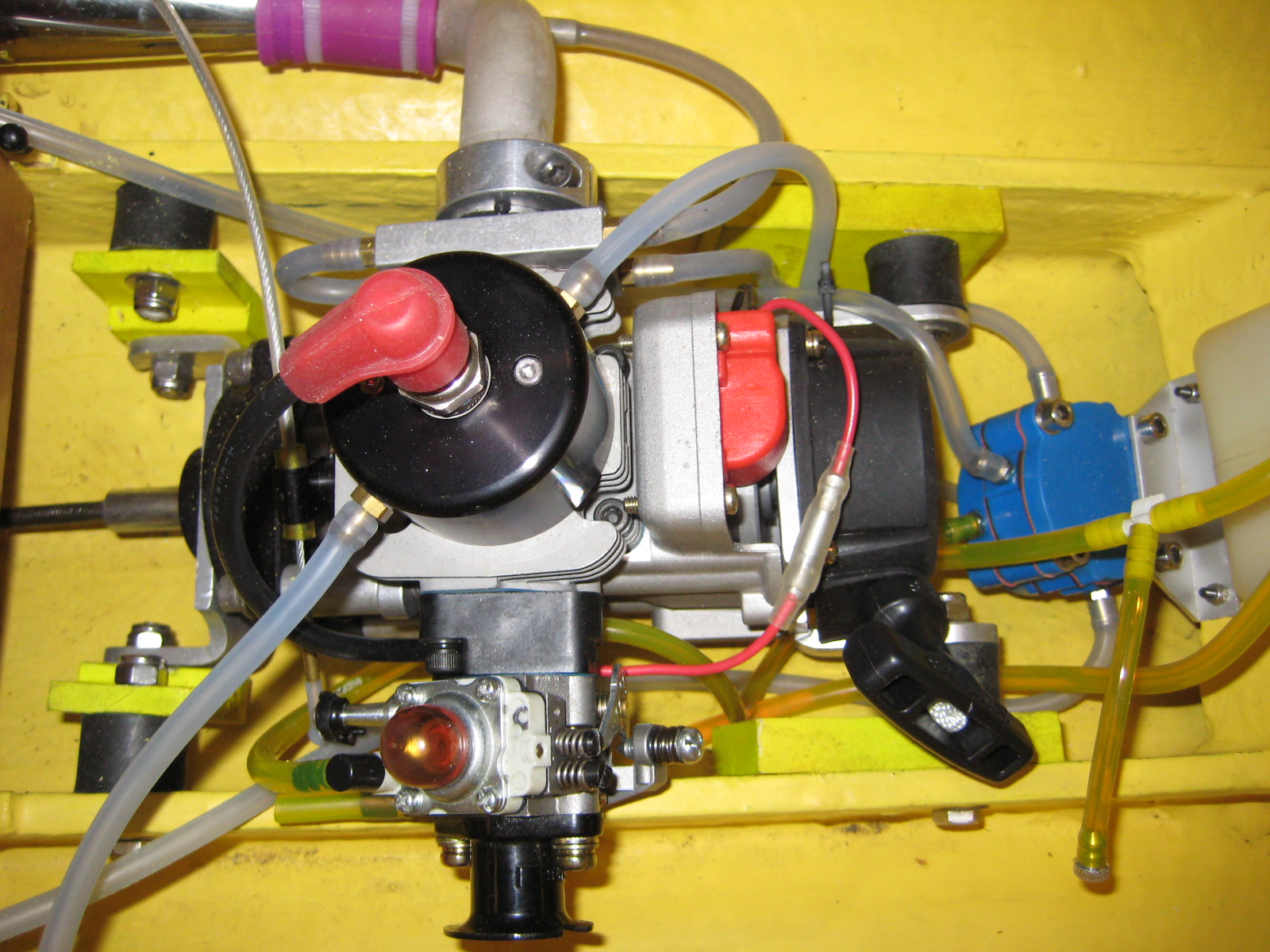

Here is an interior pic. Kinda messy. Oh well....

When in doubt, Gas it!

Please Log in or Create an account to join the conversation.

- LCYrace

- Offline

315neil1007 replied the topic: Re: Name this boat??? And cooling help.....

You'll need a shaft saver. 1/4 dia doughnut.add that up near the coupler. as many are not balanced. You'll may not get many runs in with a rubber coupler.Way to hot for them. you have a round coupler near the header. The pipe will cause the tail section to get hot as well. You may want to add a rubber grommet around the hull. Us guys up north here don't need water pumps. I have seen what warm water does on a engine in the summer. I ran my Evee with 2 water outlets in & 2 out. We Cked the head after each run last weekend. COOL the engine was very strong.

That water pic-up you added will push more water that a rudder inlet. Gotta get down on the water. Did you notice how much of the hull is in the water when on-plane in that pic BUT I've seen vees with no trim tabs.

That water pic-up you added will push more water that a rudder inlet. Gotta get down on the water. Did you notice how much of the hull is in the water when on-plane in that pic BUT I've seen vees with no trim tabs.

Last edit: 14 years 3 months ago by 315neil1007.

Please Log in or Create an account to join the conversation.

- 315neil1007

-

- Offline

- Posts: 89

- Karma: 1

- Thank you received: 3

mitchesx replied the topic: Re: Name this boat??? And cooling help.....

I caught a couple of things that Neil may not have picked up on. You probably won't need a shaft saver on it. Its a square drive, the end is square going into the motor, and the other end is in ferrule and captured at the strut where the prop is. A shaft saver would be overkill, IMO. The coupler system is pretty standard for a wet exhaust. The water being injected should help keep it cooler, and help to quiet it as well. One thought I had was to take the water pump out of the equation to test cooling. You will have to block the line for crankcase pressure that runs the pump, but if you do that and hook the water lines up direct and run it like that, you will see if it is the pump. If the pump is blocked or not working as it should, it wont matter how much water you push its way. If you do this, cap the crankcase so it doesnt leak air pressure (You'll lose compression and it will run very flat), and hook one line up from either the rudder or transom pickup to the motor, and the other to the inlet for the header.

Please Log in or Create an account to join the conversation.

- mitchesx

- Offline

- Posts: 165

- Karma: 4

- Thank you received: 2

315neil1007 replied the topic: Re: Name this boat??? And cooling help.....

like mitchesx said ,No shaft saver on 1/4 Sq I didn't notice that 1/4 sq drive. Your hull may not even need trim tabs.Or just use the one set you have. I don't have a Dumas scarab.Some hulls don't need trim tabs. The inside looks good to go. How's the radio box look. If we see something not right, I 'll say something. You should have fun driving a well setup hull.That's all that matters. The last owner probably gave up on the hull as a bust.

Please Log in or Create an account to join the conversation.

- 315neil1007

-

- Offline

- Posts: 89

- Karma: 1

- Thank you received: 3

LCYrace replied the topic: Re: Name this boat??? And cooling help.....

Thanks for the responses. I have tested the pump and currently it pumps at idle. Last weekend the pickup line must have gotten plugged with sand. After clearing the blockage it will now suck water while idling. I did increase the size of the opening on the rudder to see if I can get more flow there. See pic. Hopefully now I will have to reliable sources for the water to enter.

I think my next issue will be the prop. It currently has a Prather 270. Initially it seems to have pretty good bite but if I hit the throttle hard I get alot of cavatation and the boat just plows for about 5-10 seconds before getting up on plane. I can get a 78mm with 1.4 pitch ratio which is about 109mm in aluminium for pretty cheap through one of my distributors. I was going to try this prop to see if it will cavatate less unless someone thinks this idea is way off......

I think my next issue will be the prop. It currently has a Prather 270. Initially it seems to have pretty good bite but if I hit the throttle hard I get alot of cavatation and the boat just plows for about 5-10 seconds before getting up on plane. I can get a 78mm with 1.4 pitch ratio which is about 109mm in aluminium for pretty cheap through one of my distributors. I was going to try this prop to see if it will cavatate less unless someone thinks this idea is way off......

When in doubt, Gas it!

Please Log in or Create an account to join the conversation.

- LCYrace

- Offline

Time to create page: 0.076 seconds