Learn how to install new bearings and seals in your Zenoah engine...

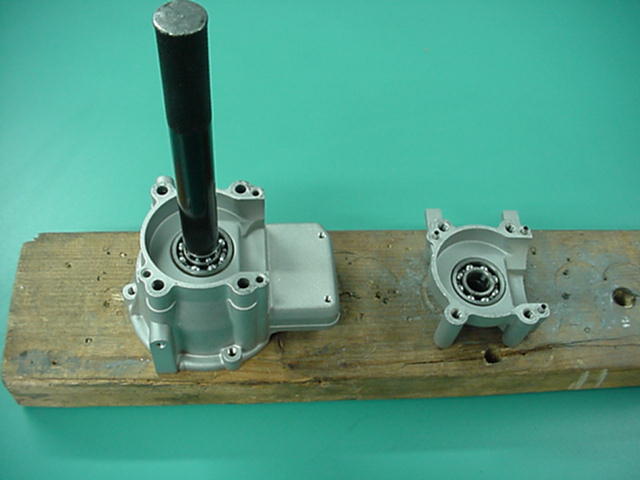

The first thing you must do is completely disassemble the engine. When you have the two case halves I would start with pushing the rubber seals out with a flat head screw driver. We have actually taken a large flat head screwdriver and rounded the edges to make the job a little easier for us since we do this often at the shop. Be careful not to scratch the machined bore where the seal will rest. After you have the seals removed, put the cases in an oven, bearing side down, at about 350 to 400 degrees F for 5 to 10 minutes. We use an economical toaster oven such as those found at Wal-Mart. Remove the cases with a pair of needle nose pliers, or something that will prevent you from getting burned, and place them on a piece of wood. You can lightly tap the bearings right out if they have not fallen out in the oven already. After letting the cases cool off, clean them with some brake or carburetor cleaner and let them dry or blow them off with some compressed air. Now you have a clean slate to work with.

Make sure the cases are completely dry. Put them back in the oven at about 350 to 400 degrees F for approximately 5 to 10 minutes. Have your new bearings clean and ready to go so that when you take the cases out of the oven you are ready to install. Harbor Freight sells a cheap little bearing and seal installer that will help you install the bearings into the hot cases without burning yourself. If you are using the little installer it makes it very easy and once you remove the cases from the oven the bearings will fall right in to the bore. After they are in the cases give them a few little taps on the outer race just to make sure they are completely seated. If you have trouble and they do not fall into place do not under any circumstance beat them down into the bore. Gently tap them out and reheat the cases and start over.

When installing the rubber seals I spray a little bit of carburetor cleaner around the outside of the rubber seal to help them slide into place. The carburetor cleaner will dry quickly after installation and the seals will no longer move. The large rubber seal you can push in until it is flush against the retaining clip between it and the bearing. Make sure not to push the little seal to far into the case as it will rub against the bearing and cause problems, it should just be flush with the outside of the case.

****Remember never install or remove bearings without heating the cases first. If you do this it will distort the bore and the bearing will not have the correct crush fit from the cases that it was designed for. Simply pressing them in or out with a press without heating the cases will more than likely destroy your cases and the bearings may actually start to fit loosely and fall out of the bore after some run time when you disassemble the engine.

Carlo

CC Racing Engines

www.cc-racingengines.com