Been having problems with a sticking carburetor because of the butterfly coming loose? Read this tech article by renowned engine builder Carlo Catalanotto and be rid of those butterfly blues!

I have seen so many instances of carbs sticking and seen

the problems from screws backing out and going through expensive engines once

removed and not re-installed correctly that I figured I would help you

guys that want to fix them yourself. This is a simple how to article on how to

fix your carb. First I would like to talk about what is actually happening that

causes this problem most of the time. We are twisting these little engines far

beyond what these carbs were ever designed for and the harmonics and vibrations

that they are subjected to is what rattles the screw that holds the butterfly

tight loose. When that screw comes loose it allows the butterfly which is not

perfectly round (It is actually egg shaped) to spin on the shaft. When it spins

on the throttle shaft that it is mounted to it does not seat in the venturi

correctly any longer. Since it will not seat correctly it will allow air

around its outside diameter of the butterfly and in turn will not allow you to

shut the engine off when you try to push your trigger forward. This problem is

only multiplied when guys use a hard linkage to the carb instead of a bell

crank system that is not attached directly. When you use a bell crank system

and you have a problem with the carb it lets you know when you can not shut the

engine off that there is a problem and you can fix it before anymore damage is

done. When you use a hard style linkage you force the carb closed and the

butterfly digs into the aluminum housing and eventually ruins the butterfly and

the carb. So for those of you who have used this method to cure you carb

problems I would re-think what you have done and hope that your blade has not

dug into the carb housing and sent aluminum through your engine.

Here is the procedure that we use here at

the shop at CC Racing Engines:

Find a clean dirt free spot

on your workbench or wherever you work on your stuff. Completely

disassemble the troublesome carb with the exception of the throttle shaft. This

is also a good time to inspect your gaskets, diaphragm and check your screen

for dirt particles. Next make sure that you have not lost the clip that

holds the shaft in place on the side of the carb, this must be in place before

you do anything else as this keeps your shaft In line.

Remove the screw out of the shaft and remove the butterfly and inspect it for

burs. If it has burs or is bent in anyway it would be best to replace it. The

next thing we need to do is clean the shaft and the screw with carb

cleaner, let it dry or blow it off with compressed air. When we re-install the

butterfly first make sure that you have a little tension from the carb return

spring on the shaft assembly. Then when installing the butterfly you will need

to make sure that the small indented nipple on the middle of the butterfly

butts up against the flat part of the throttle shaft as this is what aligns the

butterfly on the shaft.

When re-installing the screw use a very small amount of red Loctite just

enough to coat the threads. ***Note you do not need a lot of Loctite

just enough to coat the threads.*** Make sure to line up the butterfly put

the screw back in and very gently and lightly snug it. Now make sure

the shaft turns easy and the butterfly closes all the way before you completely

tighten the screw.

After you tighten the screw, Make sure that there is no loctite oozing out that

could get in between the shaft and the carb housing as it will make the carb

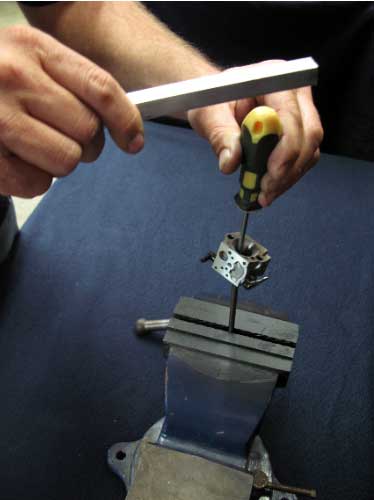

almost impossible to free up. Place the carb screw side down on top of a

Philips head screwdriver to support the throttle shaft (I use the Zenoah tool

that comes with the engine and mount it in a vice) and stake the end of the

screw that sticks thru the throttle shaft. You can do this with a center punch,

Philips head or a flathead screwdriver.

After you stake it,

it may be hard to turn the throttle shaft and this is because the

screw has pulled on the shaft a little and caused it to be slightly bent. That

is no problem as there is an easy fix. Place the carb face side down on

top of a rag or shop towel on a hard supported surface. Use a Phillip head

screw driver and place the end of the screwdriver back in the screw

as if you were going to tighten it (Again I use the Zenoah tool that comes

with the engine) and give it a gentle but firm tap to the end of the

screwdriver to straighten the shaft. Check the carb to see if it is easy to

turn as you may need to do this procedure again to get it to be completely

free. Put a couple of drops of oil on each side of the shaft and you are ready

to re-assemble the carb.

If you do this procedure correctly you will not have to

worry about your carb screw coming loose any longer as I have never had one

give me any trouble after this has been done.

Carlo

CC Racing Engines

1-504-305-5005

www.cc-racingengines.com