Scratch/Custom Build Article ...

See the development of the AWESOME turbine powered Hydroplane!!!

|

A small prospect to the future of modelgasboating…

Some time ago the first modellers in Germany started to test the possibilities of using model jet turbines in a boat. All started with turbojets, buckled on an existing hull. But this didn’t work well. 2 years ago when the first turboprop jets were available the experiments were more successful. But gearboxes were not constructed for boats, the power of the jets was not high enough and there were no clutch available to handle these engines.

But now it seems that there is a jet unit that is designed to be used inside a boat; the British WREN turboprop.

Before starting with the turboprop, here comes the chapter of building the hull.

Chris studied the technical details and numbers of the turboprop and decided to build a new hydro plane “around” this engine. Real hydros are using turboprops, so this must be a good decision. He decided for the plan of the T-4 Tandem wing hydro (Miss Budweiser) and modified the plan – like the real – to close the open areas between the wings. He scaled up the plan to a size of 1:6 (standard is 1:8), so the hydro is big enough for the turbine unit. And a big hydro promises a better handling with fewer tendencies to flip. Because when you flip the boat the turboprop will be destroyed immediately. Welcome to the real world!!!

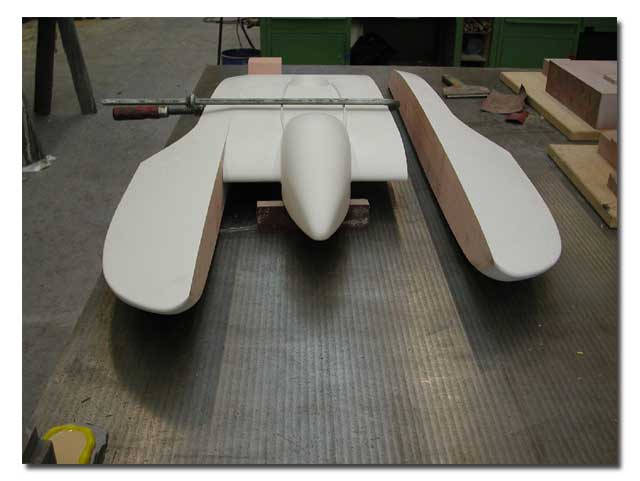

The dimensions are gorgeous: The hull length is 57’’ by a width of 27 ½’’. The height measures 11 ¼’’ but it weighs only 26 ½ lbs.

I’m not able to put the whole history of making the plug, building a mould and laminating the hull into words, so please check the pictures for all details: |

|

|

|

|

First work on the cockpit … |

|

|

… and ready for the next step. |

||

|

|

here you can see, why it means plane |

|

|

|

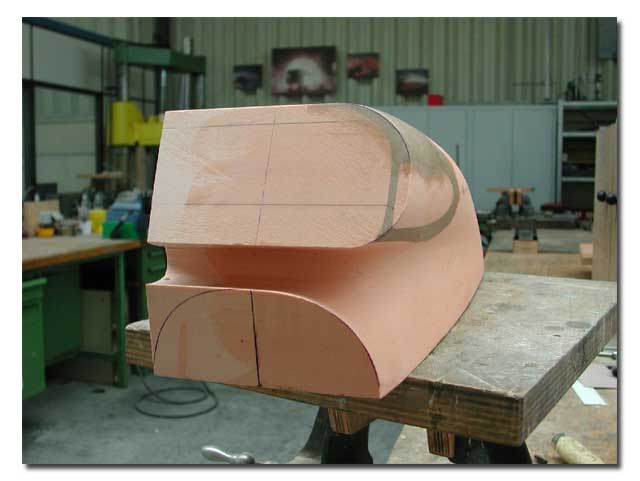

The air intake is growing up … |

|

|

|

… and ready for the plug |

|

|

|

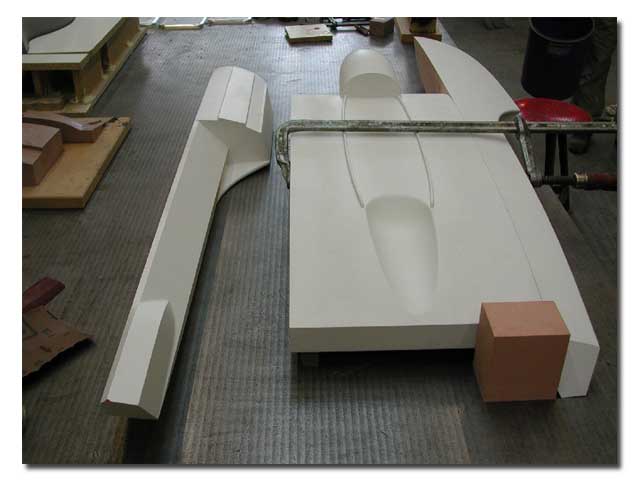

it begins to look like a hydro |

|

|

|

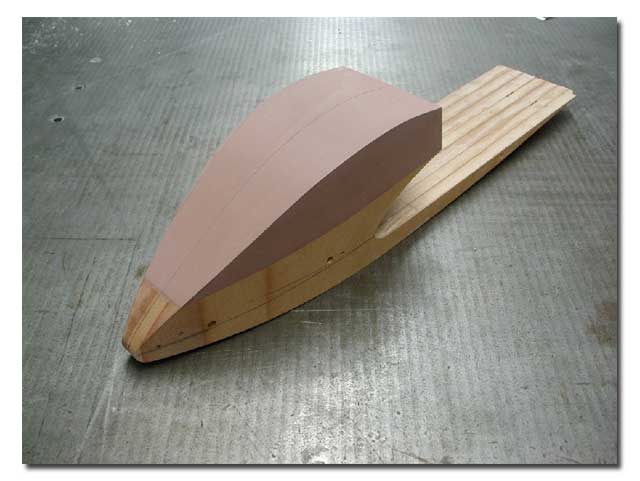

making the sponsons |

|

|

|

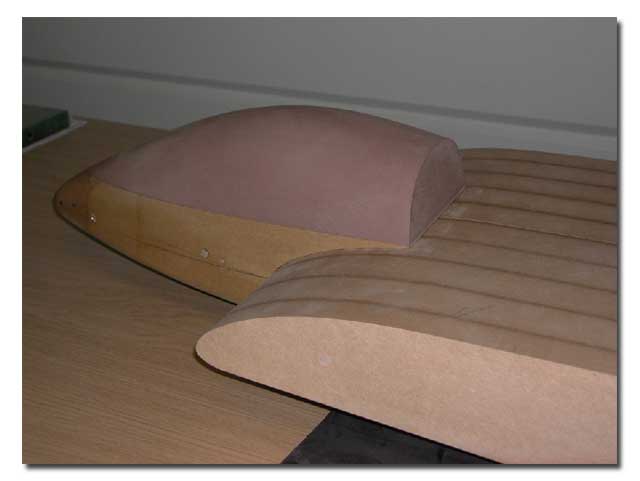

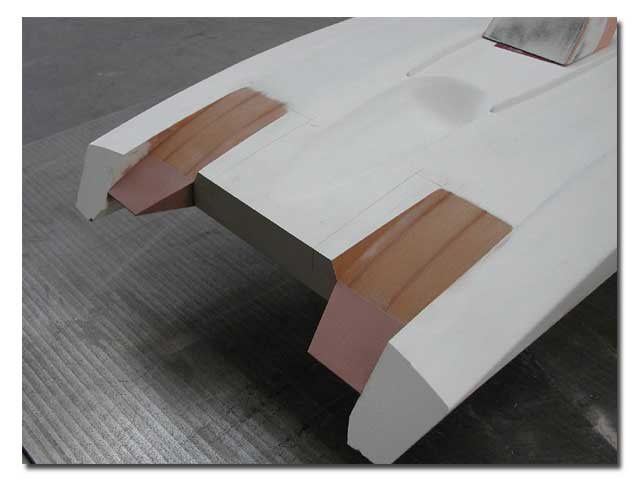

checking the fitting of the sponsons |

|

|

|

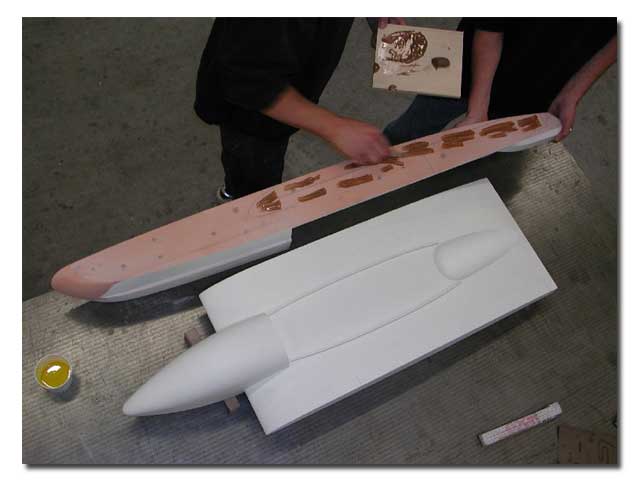

gluing the sponsons to the hull |

|

|

|

Fixing the sponsons to the hull during the gluing |

|

|

|

And it looks more like a hydro |

|

|

|

What dimensions! Chris together with the plug |

|

|

|

More details of the hull |

|

|

|

And the plug is ready! |

|

|

|

The other parts from the hull |

|

|

|

How to make the mould |

|

|

|

First layer of the special mould resin |

|

|

|

Some glass clothes |

|

|

|

A thick layer of moulding ceramics |

|

|

|

And this is the result: The first hull out of the mould, no seams, note the window frames! All made from carbon and epoxy. Every stressed area is reinforced, every bolts and nuts to fix the additional parts are glued in place. |

|

|

|

Side view |

|

|

|

|

|

|

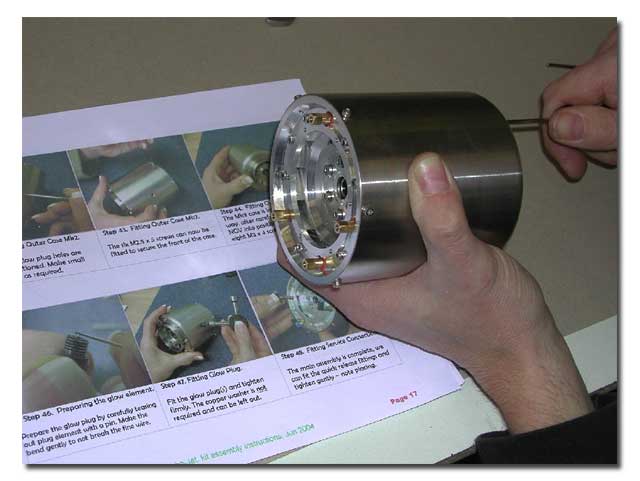

The second chapter will show you the engine. And this is nothing for beginners. The engine comes as a kit. You have to assemble it on your own. The turbine fan in the first chamber turns with a maximum of 160,000 rpm. In the second chamber the burned gases turn a second fan which is installed on an own shaft. This chamber and the both fans inside are designed in that way that the full power goes on the second drive shaft. After that the burned gases have no more power. This is how a turboprop with 2 prop shafts will work. The second prop shaft works on a gearbox to gear down the high rpms to 60,000 rpm. The second gearbox gears down to a maximum of 26,500 rpm for the prop. Here you have the power of real 9.5 hp, enough to turn a high pitched prop. The turbine burns kerosene or petroleum with 3 percent oil. It uses 5 to 6.5 ounces per minute. |

|

|

|

|

This is what you get for your money |

|

|

|

CNC machined parts, everything comes in high quality |

|

|

|

The rotor, note the blades of the fan |

|

|

|

Very good instructions, complete with pictures |

|

|

|

Small engine for a big boat, but lots of power |

|

|

|

The jet with electric starter |

|

|

|

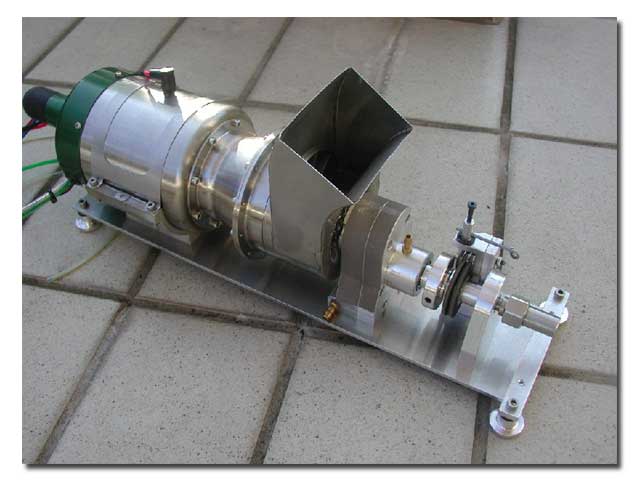

The complete unit, left the jet in the middle the touch less clutch with 2 fans inside to turn the prop shaft, after that the exhaust, on the right gearbox and brake to stop the rotating prop shaft during launching the boat |

|

|

|

The jet inside the hull. Note that Chris has built just an own hull section for testing the correct placement of the engine and for first test runs |

|

|

|

In the back the 1:6 hydro for the jet, in front of it one of Chris’ 1:8 T-4 Wing hydros, powered by an .90 nitro |

|

|

|

Cockpit with radiobox, note the embedded window frames for a seamless window installation |

|

Keep following this project, as we will have updates on performance in a future issue of MGB!