Our review of the most innovative prop reworking jig for the "Do-It-Yourself" model boat enthusiast.

Manufactured and sold by Voodoo Props, this cupping block allows prop reworking to suit the needs of those wanting more than stock Props.

* Note: The Art & Science of altering a prop's working characteristics is a non specific effort of trial and error testing. You will find a general baseline for some bending profiles that help ALL props, yet some that are best suited to a particular hull or handling issue.

Many folks feel the best way to optimize their boat performance is to have a box full of props and then just try them all until they find the best one. While this view is not wrong, it is a compromise.

Many long time R/C model boaters however, go about it a bit differently.

These boaters look at which prop gives the best handling & ease of engine handling it. Doing it this way there ultimate speeds are compromised ...but, they have tools like this that bridge the gap between a stock prop that works very well, to a modified prop that works OUTSTANDINGLY well!

Enter the world of "Do-It-Yourself" advanced prop tweaking.... Voodoo block style.

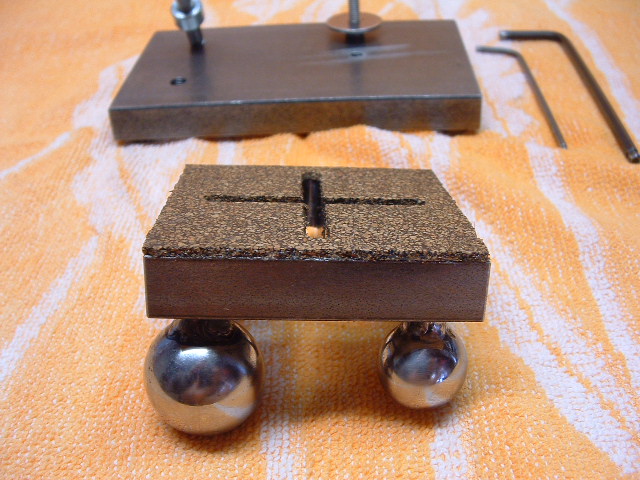

Editor's suggestion: Attach 1/16" cork to bottom of ball block. Use 3M aerosol adhesive, trim with Xacto knife.

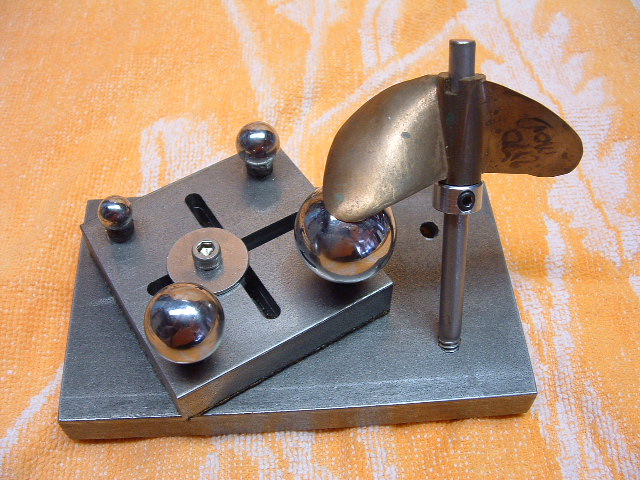

Here are some tools that are required for working with this block:

Block assembly, small brass & plastic faced Hammer, 3/32" & 5/32" Allen wrenches, Sharpy felt tip pen.

Alignment or bent blade checking

Take any one of the balls and set up your prop so the tip of ONE blade is sitting in the center of ball. Tighten the ball block to the base and place the collar under the hub of the prop and tighten it slightly. (Prop should rest in place with its tip on the center of the ball) Take a felt pen and make a line on the ball where the tip is resting.

Take any one of the balls and set up your prop so the tip of ONE blade is sitting in the center of ball. Tighten the ball block to the base and place the collar under the hub of the prop and tighten it slightly. (Prop should rest in place with its tip on the center of the ball) Take a felt pen and make a line on the ball where the tip is resting.

Now by lifting and rotating EACH prop blade onto the ball you can tell if you have a bent blade, a diameter difference, or other inconsistencies.

This alone makes the tool a very useful one. If you have ever tried reducing the diameter of a propeller and making all blades identical in length and profile you know what I am talking about! This tool makes the task easy.

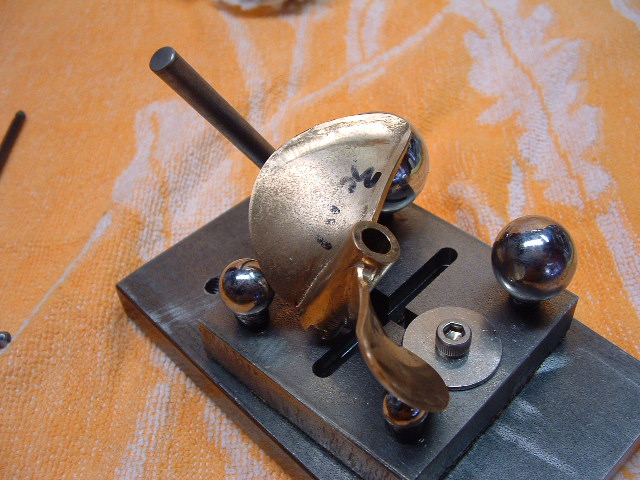

Above is a mock up of what a blade will look like if it's bent. It will either fall forward or behind the pen mark. (You may need to fool around with all the blades to find the one that is correct, then mark the ball and proceed checking from there.)

Ok, let's start bending!

In the following steps I will explain how this tool can be used.

Straight Tip Cupping:

Shown below is a prop that has round ear profile tips. Pending on the degree of cupping you want, choose a ball diameter on the block that best suits the prop you are modifying and the degree of cup wanted.

Position the ball under the prop's tip in the location of choice. Tighten the base to lock it in place. Position the collar under the hub and tighten its set-screw. Make sure the prop sets on the ball where you want it! Hammer the tip of the prop around the profile of the ball. (Practice makes perfect)

Tip cupping with a rolled edge (Camber Change):

This is a very low lift modification with very high efficiency.

This starts out just like the straight tip cupping described above BUT, don’t use the collar under hub!

Place the prop on the ball of choice in the position you want and lock the base. Take a felt pen and draw the tip's profile and position on the ball. Next draw a line on the outer edge of ALL the blades at approximately 1/3 the distance from trailing tip to hub. (This distance is adjustable based on the degree and position of camber change desired.) Now allow the prop to sweep across the ball and where and when the line on prop gets to the top of the ball, mark a line on the ball. When done your ball should look like the second picture below.

Setting the ball size and the position for this operation requires 2 VERY important items to be in place !

#1 The ball diameter and radius of that ball needs to be very close to the blade's profile at the 1/3 pen mark when viewed from underneath.

#2 The placement of the ball on the tip to be cupped is still where you want it to be.

** The 1/3 position may need to be more or less pending on blades profile, or you might have to use a different size ball **

Once you are satisfied that the range of sweep across the ball will give the profile you want, hammer it slowly starting at the tip matching up the felt mark, sweeping the prop over the ball until the 1/3 line matches up. Repeat on all blades.

The picture below shows what a blade should look like when done properly. You can see the slight denting the ball makes to face of the prop. The camber change can be noted as well, feathering out to "0" at the 1/3 of the blade.

**** Special Note: When cupping ANY prop, star tip or round ear...the ramping on the trailing edge of the prop MUST be removed prior to pounding it on the block. (The ramping only needs to be removed for the distance the ball will be in contact with the trailing edge.)

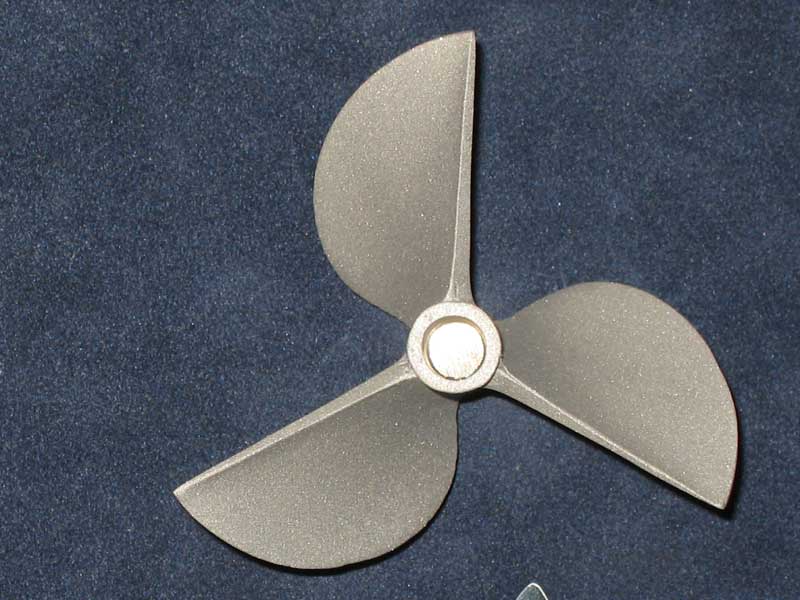

Here some random photos of cupped props. Kind of a mixed bag of styles, but it shows the degree of bending that can be done. The last picture is the ULTIMATE home brew prop reworking shop tools... the Voodoo prop block featured in this article, the CC Racing Engines dial indicator pitch gauge and the Gas RC Products magnetic balancer.

Enjoy!

Scott

Gregg Khiele, Voodoo Props LLC.

Voodoo Props LLC is a Michigan based manufacture of R/C model boat propellers for the Gas, Nitro and Electric model boaters. Voodoo was the first in model R/C boats to introduce 17-4 PH stainless steel and 376 silicon bronze propellers to the market place.

Contact Information:

Voodoo Props LLCOwner: Gregg Khiele

14049 Provim Forest Ct.

Shelby Twp., MI 48315

www.voodooprops.com

Tel: (586) 707-4734