Product Review Article... by Scott Schneider

Our review of the new RCMK RZ254 Evo - Rear Exhaust engine...

You should, by now, be well aware that the engineers at RCMK are always focused forward in engineering products we RC boaters worldwide would love to have. If your desires have been for a "Pull starter equipped", rear exhaust engine that fits where a side exhaust engine you now own resides, or you simply want a newer sleaker boat designed around it...look no further!

What we have here is such an engine. The RCMK "RZ-254 EVO". Based on the now refined and improved S-254 EVO, the "RZ" is that same engine with the cylinder and coil rotated 90 degrees placing the exhaust out over the PTO end of the engine and the carburetor above the starter.

Most of the specifications of the RZ254 EVO are the same as those of the S254 EVO. You can refer to our S254 EVO engine review here.

Most of the specifications of the RZ254 EVO are the same as those of the S254 EVO. You can refer to our S254 EVO engine review here.

** Within the North American market, all RZ series engines are being sold with the mounts shown. Gizmomotors engineered the mounts and has them custom made specific for RZ applications. The magneto-side mount is RZ use specific while the PTO end fits all RCMK & Zenoahs. *See the MGB review of Gizmomotors "Life Time Mounts" for more information (coming soon).

Rubber isolators spacing, "center-to-center" is 5 7/8" - 6". Stringer/rail spacing is 5".

A special "Drop" PTO end mount is avalible as well from Gizmomotors. * It will increase the center line spacing by approximately 9/16 -5/8".

A special "Drop" PTO end mount is avalible as well from Gizmomotors. * It will increase the center line spacing by approximately 9/16 -5/8".

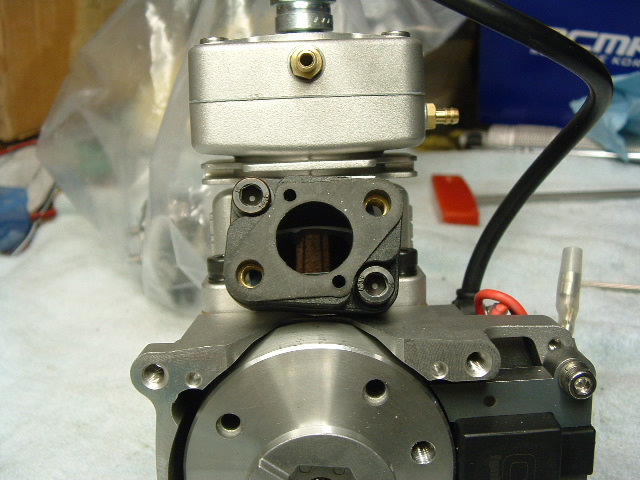

Engine view showing how compactand narrow the upper engine is.

Cowl coverage requirements on low profile type hulls will be a lot less with no carburetor or exhaust parts on the sides. |

Side view showing again the compact nature of the RZ layout. The secondary coil is now mounted on tabs on the side of the case right next to the sourse coil. Wires can be wraped up and tucked away in the gap between them.

|

Viewed from this side, not much going on.

The only thing will be a throttle linkage of the user's choice, nothing provided with the engine at this time for carburetor shaft rotation. |

Based on its side-exhaust brother the "S-254 EVO" that has already proven itself on dyno tests exceding 5 HP and a tad over 2 foot-pounds of torque, the RZ should, for a production cast-block integral head rear-exhaust engine, have the most power "out of the box" one can currently purchase.

Another plus is the narrow engine width which will allow placement in the sponson areas of large scale cats.

Hydros and riggers can use sleaker cowling designs with less frontal area offering greater aerodynamics.

One thing that must be taken into consideration with the rear-exhaust engines if retrofitting it in a boat which currently has a side-exhaust engine, is the fact that all of the pipe is behind the engine. This in turn makes for a slightly longer engine-pipe combination (approximately 2 - 2.5" depending on setup). In some cases, especially when using heavy tuned pipes, this can pull the CG (center of gravity) a little bit towards the back of the boat. This can easilly be compensated with a little bit of weight up front or moving the engine slightly forward. In new installations this should pose no problems at all...proceed with setting your boat's CG as you wood with any engine/pipe combination.

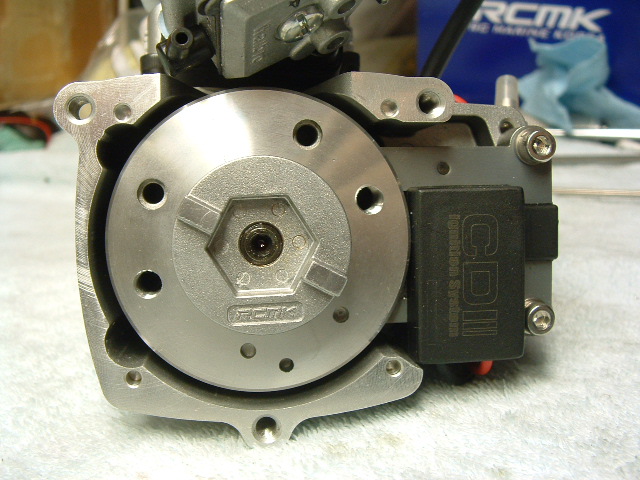

Ignition layout is typical enough, though as stated all items are rotated 90 degrees. The coil and starter dog are all the same as an "S" version. The flywheel also, though the keyway is cut 90 degrees for this RZ application.

|

The intake manifold is a "S" version part as well.

The fit is tight without a doubt, all the parts just clear each other which helps keep it all quite compact. |

With the manifold removed the machining of the intake portion of the actual cylinder becomes evident.

RCMK has cut a steep angle, allowing the manifold and the carburetor to tilt upwards so it clears starter assembly. |

* Gizmomotors should have a stainless steel 7/8" header that can use the current "No Leak" type manifolds by the time this article go's live...great news !

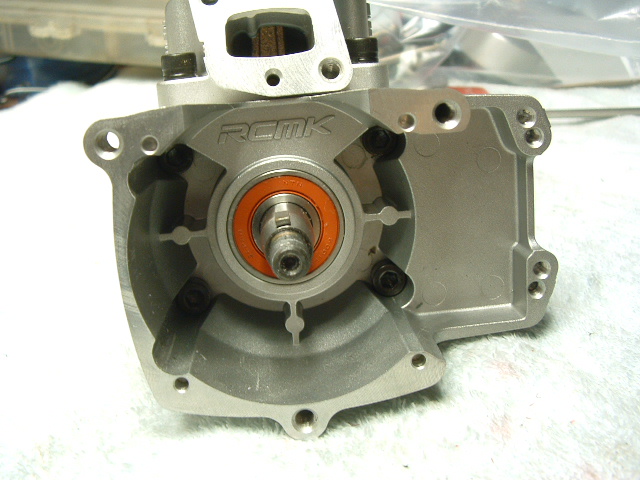

With the flywheel removed we get a better view of just how beefy the RZ cases are cast!

All the case material surrounding the flywheel is as thick and solid as it looks. No whimpy castings here! RCMK learned from other models where not to skimp making these cases really solid and well thought out. |

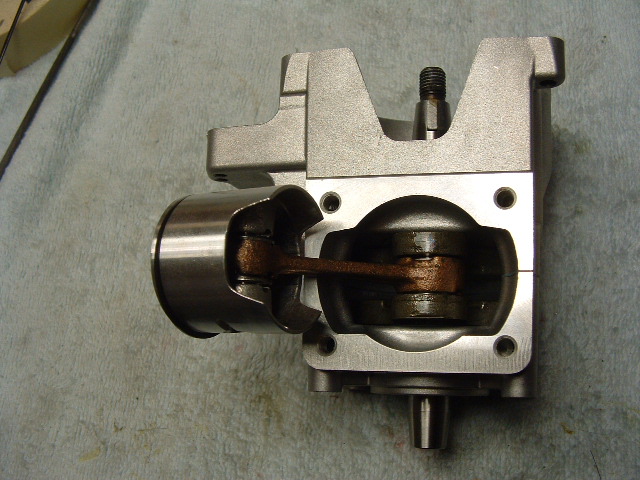

Cylinder removed showing what we all know now as the "EVO" cylinder casting.

*Due to the angled machining of the intake manifold area, there is NO interchange between "RZ" and "S" engine cylinders. |

A better shot of the intake manifold area.

Notice a small bit of machining done on the roof of port. This aligns the manifold's roof. Interesting note: During the S-254 EVO review noted was the steep downward angle of the EVO intake tract. Here it becomes more obvious as to why. With the angled manifold now on the RZ intake tract, the flowpath is now straighter within it. |

Unfortunately I am unable to provide an "On-water" performance report on how the RZ runs at this time. This reviewer is currently building a new rigger specific to the RZ's design attributes and will be doing on-water testing in spring 2010.

* Note: Performance should be very equal to the current side exhaust S-254 EVO and by design hopefully have a tad more!

Viewed without cylinder, the transfer feed cut-aways and the cylinder's skirt clearance areas can be seen better.

You will notice that the area of the cases left and right are the transfer feed and top and bottom for cylinder. * The lump of material just down from the gasket surface on each transfer feed is required because the case-half bolts pass through and need to be covered. * Also note the cylinder's hold-down bolts are darn near right on top of the case-half bolts' path. SHORTER cylinder securing bolts are fitted by RCMK for the RZ application. If updating to stainless steel fasteners you MUST be aware of this! |

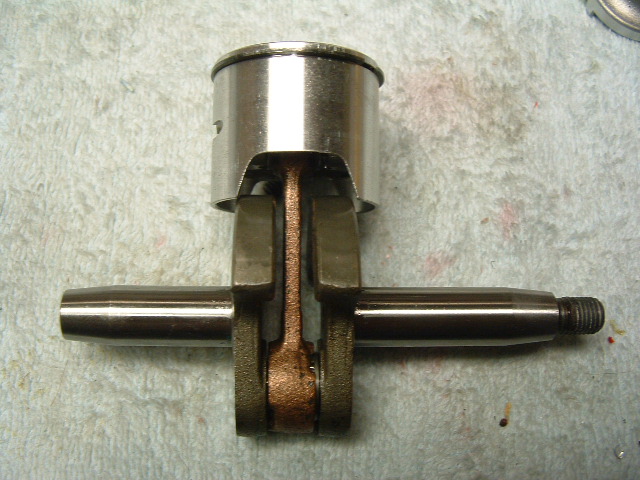

The crankshaft is the same as all other RCMK engines.

The piston however is RZ specific. (Though early R-254 pistons interchange). The wrist pin location is rotated 90 degrees as is the ring index pin. The skirt cut-away retains the same profile as before. The wrist pin bearing and thrust washers are the same as the "S" version. * RZ * R254 wrist pins have a teflon plug within the hollow portion so no air/fuel can pass through it. |

Cases view here show the beef again where RCMK has provided the secondary coil lugs but cast them into strengtheners behind the source coil area.

Crank shaft bearings/seals along with a brass seal plate are the same as "S" version EVO engines reviewed before. * Note also as with all RCMK engines, provided are two sets of coil mounting holes for those wishing to change the timing specs. The stock position when viewed from the starter side is the lower set as shown in the first few pictures. |

Happy Boating,

Scott Schneider

Modelgasboats.com Technical advisor

GIZMOMOTORS (Exlclusive US Distributor of RCMK Products)

550 Grove Dr.

Bartow, FL

Phone: 863-533-6060

33830 USA

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Website: www.gizmomotors.com

Bartow, FL

Phone: 863-533-6060

33830 USA

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Website: www.gizmomotors.com