Review of the RCMK S-254 "EVO" R.C. marine boat engine.

Welcome back to MGB for the next chapter in Radio Control Boat Engine evolution ...

If you are one of those who have been sitting back waiting and watching RCMK get there feet wet in the wild world of performance R.C. boat engines, wait no longer! The S-254 EVOLUTION ... "EVO" has arrived being even tougher and more powerful than ever.

The first generation S-254's took the RC boating world by storm setting the bar higher than any other cast production engine produced before it.

In the 6 months or so it's been getting well used around the globe, some troubled areas have required improvements. Some teething pains in R&D undiscovered in the lab and pond testing were discovered in the field of consumer use and abuse.

RCMK's commitment to the hobby and this engine's development has been 110%, listening to those around the world critiquing on what was right or wrong with the first generation S-254 engine.

So we arrive here taking an indepth look inside the New RCMK S-254 "EVO".

RCMK listened ... The result is the S-254 "EVO" version having been upgraded from cases to the top end.

It may very well look similar, but with detailed observation, it is very much improved upon.

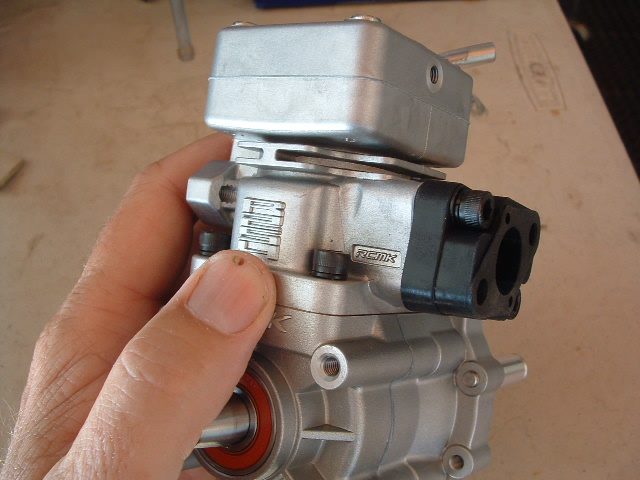

Note: Fit and finish, Casting quality, General appearance being all first rate.

** These reviews ONLY reflect the CURRENT product at time of writing. The original S-254 was at time of review in the hands of very few users.

Issues that were to prompt these upgrades were unknown and therefore not shared within the original article.

* Note: The "S" desination is for the Side exhaust layout & cast crankcase. "EVO" is using the newest cylinder design which will be used throughout the RCMK line from this point forward.

Read on ..............

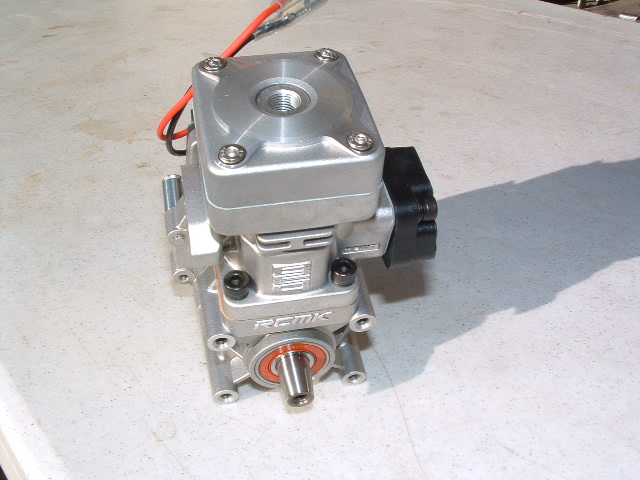

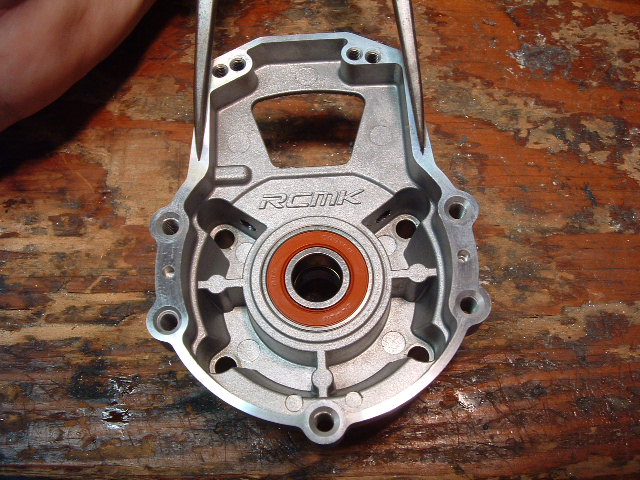

** Crank cases

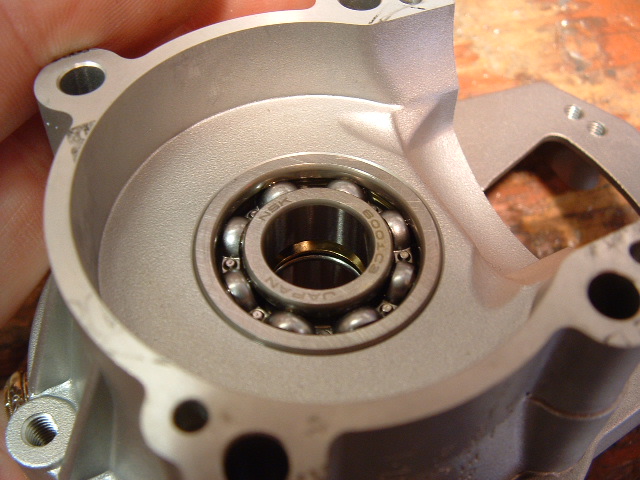

Air leak issues arose with the original outboard bearings having only single seals This was corrected right away having both inboard and outboard seals.

( Damaged seals / bearings on first generation S-254's were being replaced in the United States by Gizmo Motors )

* Now the cases are fitted with Double-Sealed Bearings of even higher quality. Also fitted is a Brass Mechanical Seal Plate that acts like a thin zero drag seal between the inner and outer bearing of each side. Air leak issues are a thing of the past ... Nice touch !

Crankcase pressure on bearing seals is much reduced with reliability improved substantially.

Also addressed is a slightlyTighter Fit of the bearings O.D. to the case's I.D. preventing outboard bearing movement within the case.

The next issue addressed was that of the coil mount area of the case. Some applications showed weakness and subsequent failures requiring a Beefing Up of the entire Coil Mount Tower Area.

The "EVO" case has a much heavier casting thickness along with a strengthening web in this area preventing flex and vibration from causing further trouble.

Note: Brass seal plate under the bearing and thicker casting in the coil support area.

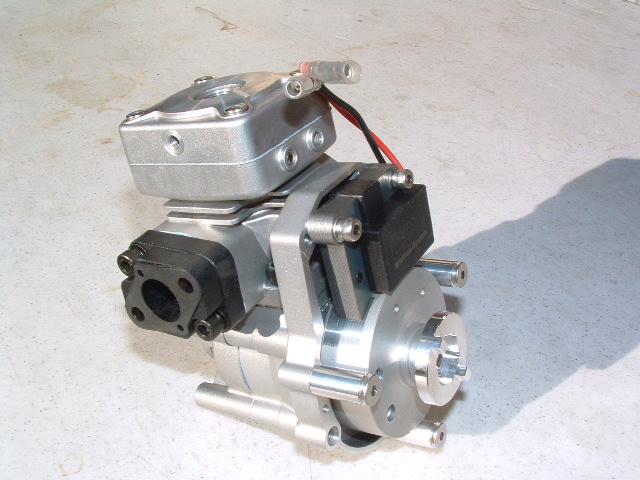

** Ignition / Starter Area

Here RCMK has tightened up the specifications on Secondary Coils, no longer should we have issues with sporadic coil failures.

Starter Drive Dog length has been reduced so the use of "thin" motor mounts should not cause engagement troubles. ** Check TIGHTNESS of start dog prior to running engine the first time ! ... Add more loc-tite and Snug it down tighter than it comes from factory !

( If mounts used are VERY thin, there is no harm in placing a single #10 washer under each post )

The starter assembly receives a New Handle with a much improved profile for a better grip.

Nice handle shape .... Get a Grip !

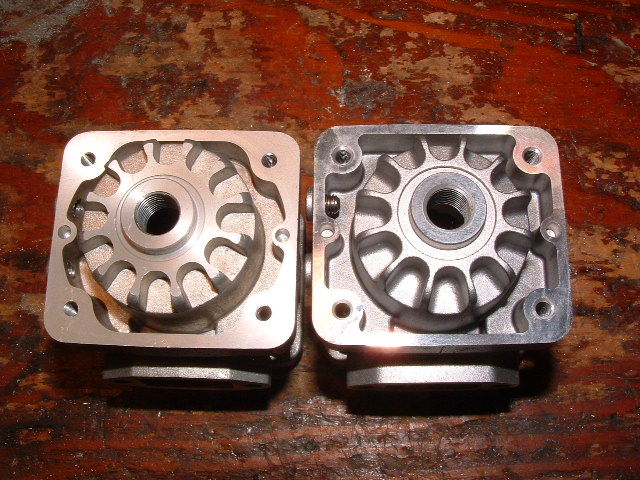

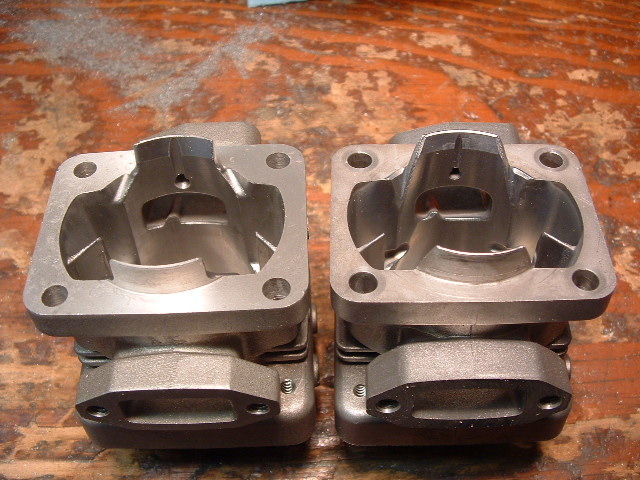

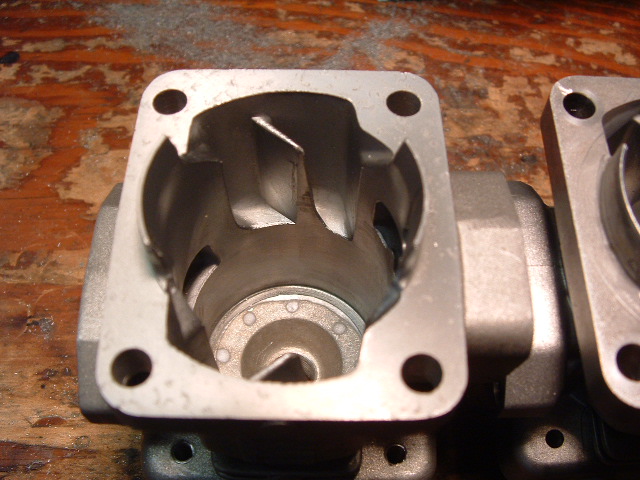

** Cylinder / Water jacket

The "EVO" uses an Entirely NEW R-254 Cylinder having nothing but the basic shape remaining the same.

* The New "EVO" style R-254 cylinder will be used on ALL future RCMK "S", "SX", "RZ" model engines.

The cylinder casting is now an even higher grade injection casting of very high density allowing much better fine detail to be added.

The quality of the chrome bore and finish honing is just outstanding!

Chrome is applied very evenly with NO bore voids or defects visible. The chrome when tested was VERY hard offering long wear characteristics.

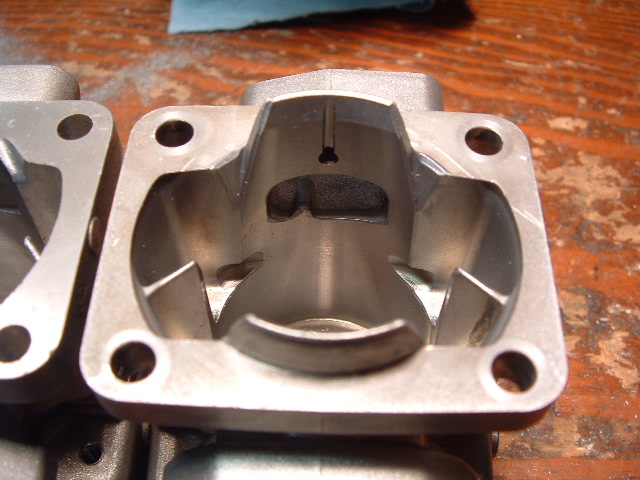

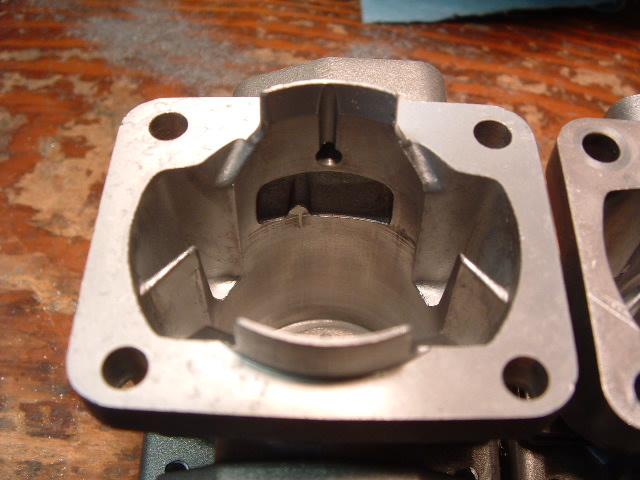

** Exhaust flange

The exhaust flange now ends up Slightly Longer and Cut Square and no longer has the angled face profile.

It has Support Webs inboard of the mounting bolt holes beefing it up as well.

The Shape of the Exhaust Outlet / Port is changed now having a very pronounced arched roof profile, unlike the original's flat roof.

The height of the exhaust port (at peak of arch) is giving a duration spec of @ 174 /175 degrees.

Sides of the exhaust port are now steeply wedge shaped being narrower at the bottom of the port and wider on top.

Overall the exhaust ports area is less than the original though slightly higher timed.

NOTE: * Double cylinder images are ORIGINAL R-254 on left ..."EVO" on right

Note: Water jacket area. Exhaust flange shape and web support. Exhaust and transfer window shapes.

** Intake Port

The Shape of the actual intake port is now closer to an elliptical oval rather that the original's rectangular shape. The intake passage out to the intake manifold is slightly smaller matching the manifold's shape at the gasket junction which remains the same.

( Idea here was to increase velocity within the intake tract giving a torque boost ).

A ring compression nub is still cast into the roof of the intake port, though it never contacts with the single ring's end gap ( So why for??)

The impulse hole is now smaller going through the casting adding a tad more surface area under the intake port.

* Interesting also is a change in sweep angle of the actual port. It now has a more downward slope profile to it having the flow of air/fuel headed steeper downward within it.

( The newly redesigned RZ rear exhaust will take advantage of this angle change best )

Intake's open duration is @ 152 - 153 degrees.

Note: Intake port shape & area. Gasket margin & window shape.

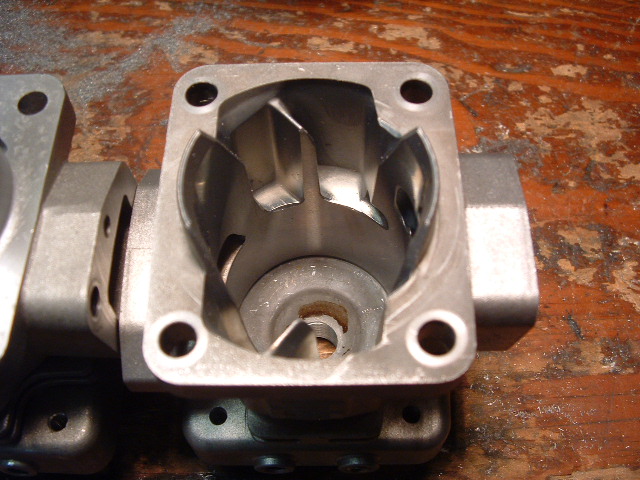

** Transfer Passages

Within the "EVO" cylinder transfer passages, the width of the outer edge at the base gasket is narrower having the actual transfer passage wider adding volume within them.

The divider bridge between the transfer ports has been Cast in at a Different Angle changing the ratio of flow each transfer port gets.

This change has made the exhaust side transfer window much larger.

(No longer a narrow port opening as it was before.)

The intake side transfer window is a tad *smaller.

*Here is where the "EVO" has incorporated an"Eyebrow" modification to the back edge of the intake side window increasing its area substantially. ** What’s so great is the eyebrow cut is being done to the raw aluminum casting PRIOR to the chroming process, so the widened port window, along with all the ports, gets chamfered all around then chromed. That’s REALLY a great way to do it.

( Transfer open duration @ 126 degrees )

Alterations were also made on the Entry Angle of exhaust side transfer window having the port's edge closest exhaust port aimed more sharply towards the intake side of the cylinder.

( This aids in less charge short circuiting )

* Overall flow volume within the transfer passages and out the window of each port has increased with better directional control and accuracy.

* EVO on left * Note: Divider bridge postion change. Ports area change. Eyebrows. Head/squish quality.

** Cylinder Head & Squish

The new "EVO" cylinder casting has a More Accurate Combustion Chamber Shape with a squish band that is more uniform.

Squish clearance is coming from the factory at @ +/- .020”.... Nice and tight profiled to match the machined piston dome.

** Water Jacket and Cap

The area within the Water Cooling Space has been opened up adding Greater Water Volume.

Fluting on top of the head area is now taller adding more surface area to absorb heat.

The cylinder cap is new as well having increased volume matching the cut away area of the new cylinder.

Together the added water volume surrounding the top end should further reduce operating temp in warmer climates & water.

Water fitting locations remain unchanged.

*Cylinder cap water fitting is now screwed straight in, NOT angled as before.

** Piston and Ring

The ring is now made of a Different Material, with the machined face of the ring altered for Faster Ring Seating.

The piston no longer has the vent ports like before. Piston profile is still a tapered design dome to skirt having a slight cam grind profile which makes the piston slightly narrower across the pin bosses and wider across the skirts.

* Cylinder is now held down onto the cases with Longer Bolts making the cylinder more secure with less chance of it coming loose.

** "EVO" R-254 Cylinders are easy to spot from the original R-254 having an RCMK logo cast into side of the intake port area and having a square exhaust flange with support webbing inboard of the bolt holes.

*** ALL parts interchange between original S-254's and the "EVO" S-254 versions ***

** Performance and real world running

The S-254 "EVO" has been independently tested on both inertia and break type dynamometers showing the S-254 "EVO" to produce just over 5 horsepower with a tad over 2 foot pounds of torque using a tuned pipe.

Peak RPM pending on load is in the 17-18K range ... Truely a screamer right out of the box!

That is pretty healthy for a production "box stock engine"... actually it is VERY healthy.

Performance numbers between old and new are pretty close, the "EVO" upgrades of lower case areas were mostly one of structural integrity and reliablity, while the NEW "EVO"cylinder offers greater torque with a broader powerband. Together a real winner!

Setting up the RCMK S-254 "EVO" is a piece of cake. It fits right into place on Zenoah mounts with shaft / throttle alignments remaining unchanged.

Well, this just one engine RCMK has been reworking these past months, not too bad a job either.

The future looks very bright for even more products coming out of Korea for the RC boating enthusiast.

Happy Boating,

Scott Schneider

Modelgasboats.com Technical advisor

Contact Information

GIZMOMOTORS (Exlclusive US Distributor of RCMK Products)

550 Grove Dr.Bartow, FL

Phone: 863-533-6060

33830 USA

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Website: www.gizmomotors.com