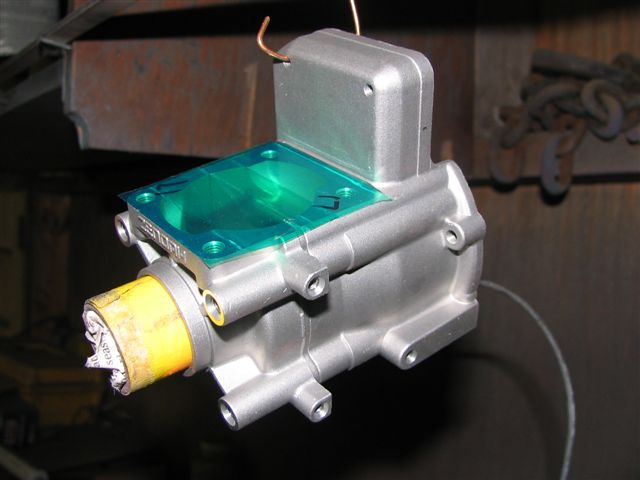

Add some color to your motor...match it to your boat's theme...it's easy with these powdercoated parts!

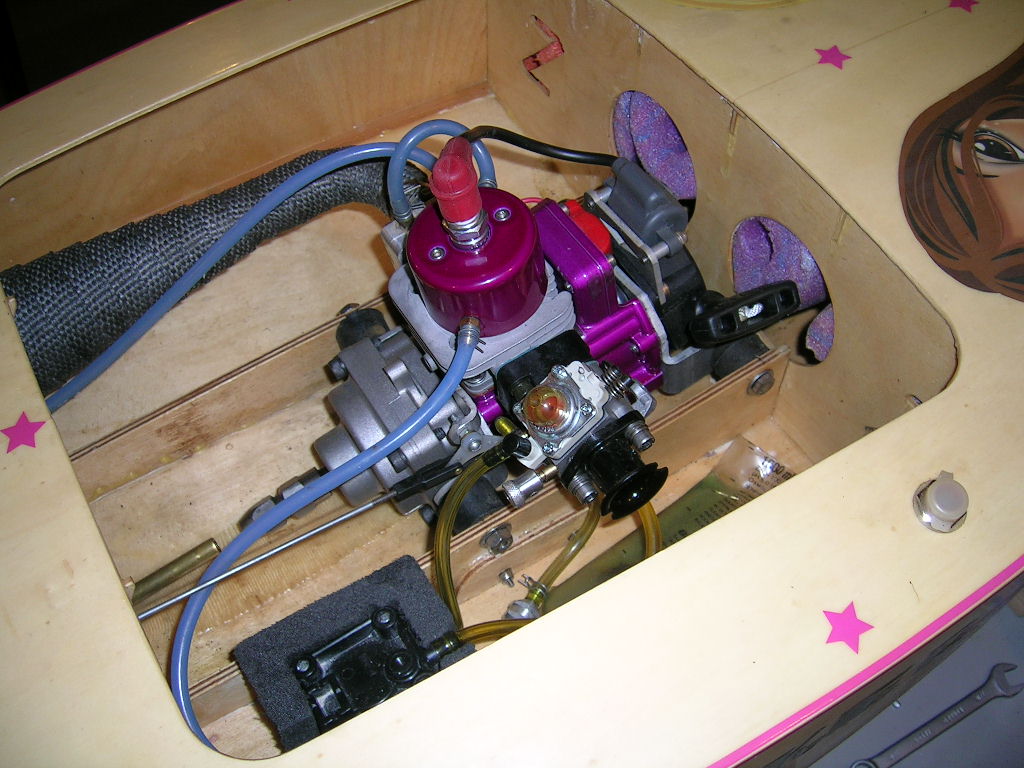

A while back I built an I-Box Crackerbox from Zippkits. I decided to do a "Bratz" theme on the boat for my daughters. The boat turned out really nice, but when I saw these custom powder coated engine parts by Corbin Martin I knew it would look even better with a matching engine!

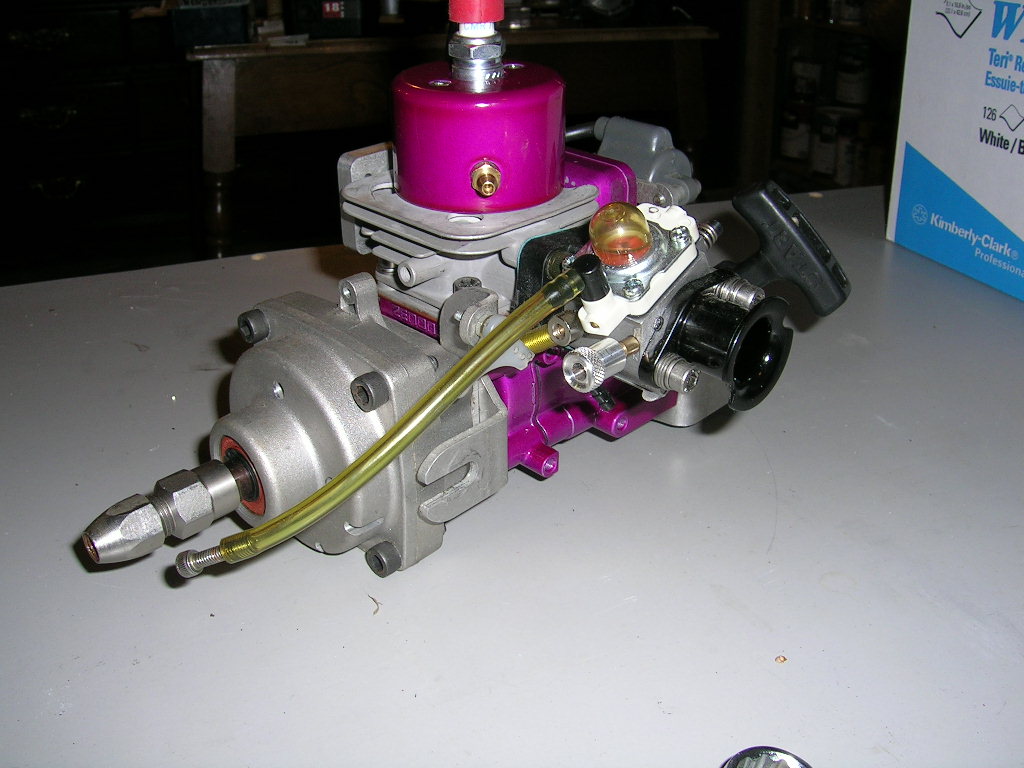

I contacted Corbin via Email and he responded quickly. I told him I was looking for a pink case and cooling cap for my boat. He informed me that he didn't have hot pink but that he would do his best mixing colors he had to get it as close as possible. When I received the parts I was really pleased with the way they turned out. The color and finish were excellent.

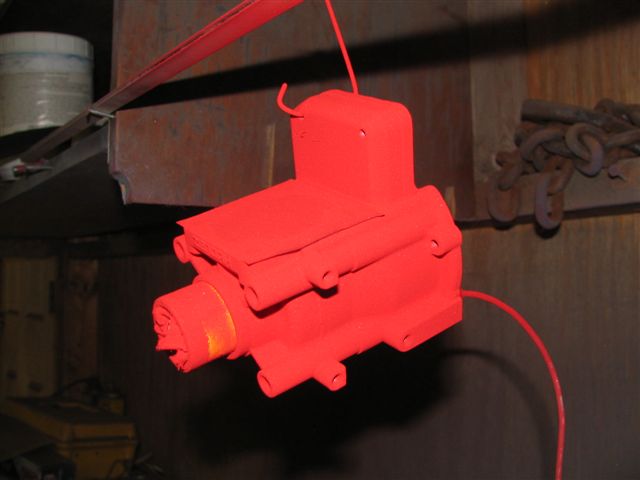

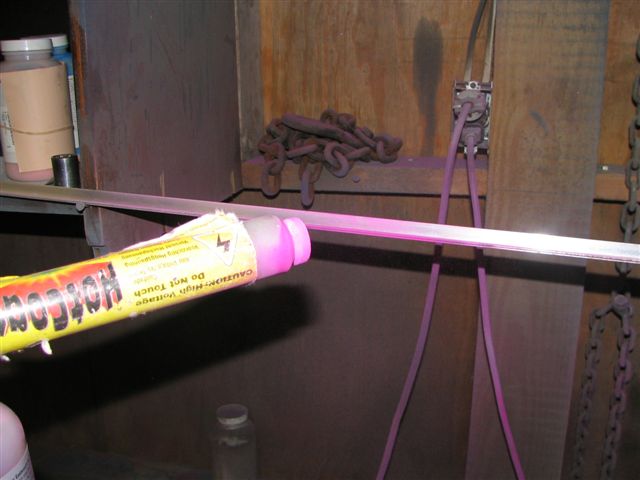

Here Corbin explains a little about the process of powder coating the parts:

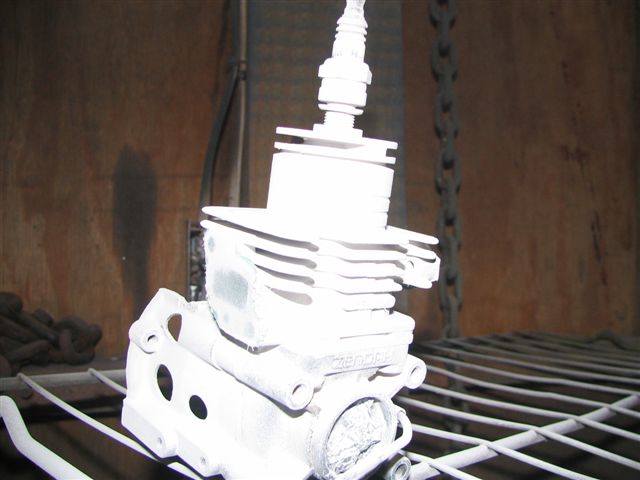

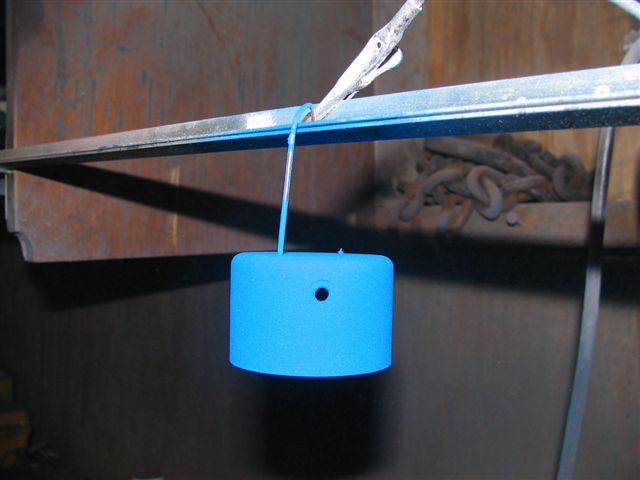

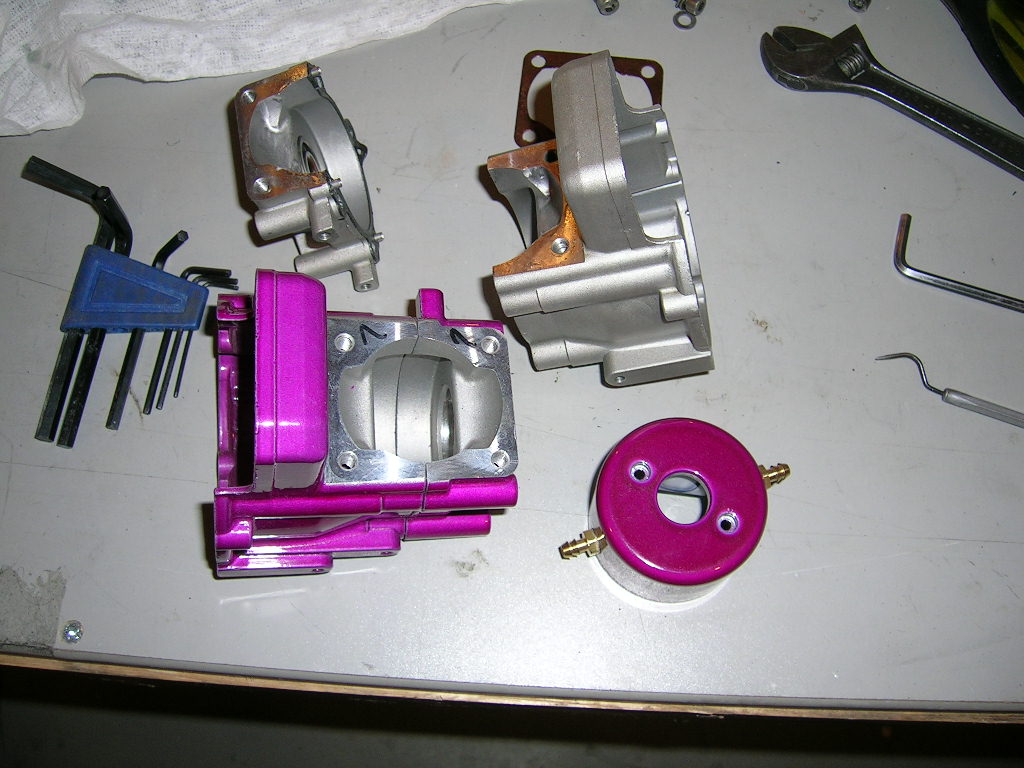

Here are a few things I noticed with the powder coated parts. First the cooling jacket had some residue on the lower lip where the large Oring sits. This was easily cleaned out with a flat screwdriver. You want to make sure the Oring seating surfaces are clean in order to get proper sealing of the cooling jacket.

Also, for the cases, I ran into a slight problem when heating them to install new bearings. I usually heat the cases up with a small torch and drop in the cool bearings. With powder coated cases you should heat the cases in an oven at 325-350 degrees F, no more. Otherwise the coating could begin to liquefy. This happened to me when heating the cases with a torch. Luckily I didn't damage the finish too much so it hardly shows, but keep this in mind when you install bearings in your cases. Heat in an oven at controlled temperature and handle them very carefully!

When working with the powder coated parts, you want handle them carefully. The coating is resistant but at the same time seems to be brittle and can chip easily if improperly handled. I noticed this when taking away the residue in the cooling jacket. So you want to avoid nicking the finish where is will be apparent. Under normal use, I think the finish will last a very long time though.

I asked Corbin about coating cylinders and he reported good long term results with all parts including cases, cooling caps and cylinders.

If you are looking to dress up your boat a little, consider getting some of these custom powder coated parts!

Pricing: $40 for new powder coated Cases (matching pair) and Cooling Cap. $25 if parts are supplied by customer

$20 for powder coating a Cylinder (customer supplies cylinder)

* prices valid at time of writing this article. Contact Corbin Martin for confirmation of prices.

Happy Boating!

Contact Information

Corbin Martin

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.