Product Review Article ...by Rudy Hilado

A look at the Evolution Rigger by Frank Bonanno.

After building and racing Deep-V boats and catamarans, I was getting itchy to try something new...and really FAST. I decided to make the step up to an outrigger hull. This style of boat has the potential to be very fast due to the light weight and minimal boat area that is actually in the water when at speed.

A rigger seems like a fairly straight forward design that would be simple to build, but I think the looks can be deceiving. Typically there is a tremendous amount of research and testing that goes into a rigger design. The sponson shape, placement and angle are all critical to the performance of the boat, as well as the center of gravity, overall length, width and hardware placement. While there are a few riggers made from fiberglass or composite materials, most riggers are hand built from wood. Since my wood working skills do not exceed the capability to make a radio box, I opted to purchased a boat built by a much better craftsman.

After a little bit of research I decided to purchase a rigger boat designed and built by Frank Bonanno II, based in New Jersey. His rigger is called the Evolution. While some gas riggers are converted nitro 90 riggers, the Evolution is designed from the ground up as a gas boat.

The purchase process went very smoothly. Frank made every effort to communicate the status of the boat while he built it. Frank let me know up front when he would start working on the boat and how long it would take to complete. He sent pictures of the boat as soon as it was done and it was completed and shipped exactly as expected.

The boat can be built to different levels of completion. The basic assembled hull includes the unsealed tub, sponsons, hatch, turn fin, motor mount, servo mount blocks, and stuffing tube. Additional work can include sealing all the wood parts with 4 very thin coats of epoxy, which keeps the boat extremely light. The next level of completion includes mounting of the transom hardware and completion of the radio box. Frank is very accommodating, and you can probably have the boat built to virtually any level of customization.

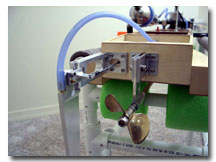

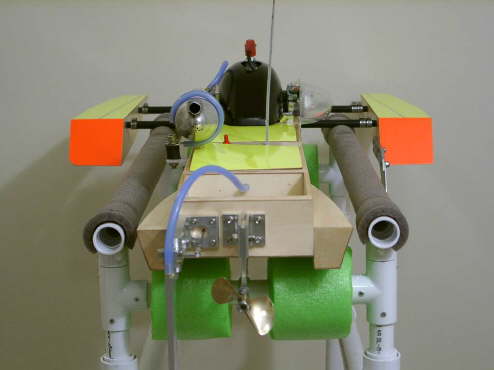

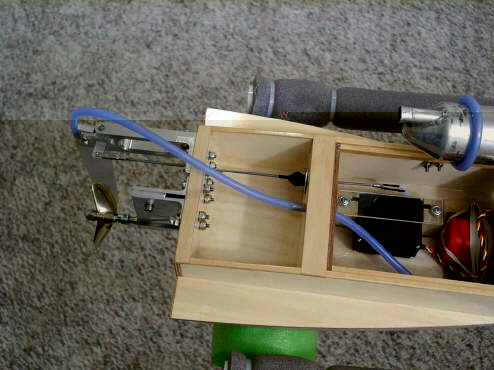

I decided to seal the boat myself and mount my own hardware (SpeedMaster). I mounted the hardware first following very exact instructions provided by Frank, which places the rudder on the left side of the prop. I then removed it all again before sealing the wood. I sealed the boat following Frank's recommendations, which meant applying a coat of West  System epoxy then wiping it off, leaving only a very thin layer. I let it dry, then repeated the process 3 more times. It took several days to finish this way as the epoxy had to dry overnight. Instead of painting the boat I covered it with fluorescent yellow monocote strips and added some nice decals created by David Kereluk of Vinyl Graffiti.

System epoxy then wiping it off, leaving only a very thin layer. I let it dry, then repeated the process 3 more times. It took several days to finish this way as the epoxy had to dry overnight. Instead of painting the boat I covered it with fluorescent yellow monocote strips and added some nice decals created by David Kereluk of Vinyl Graffiti.

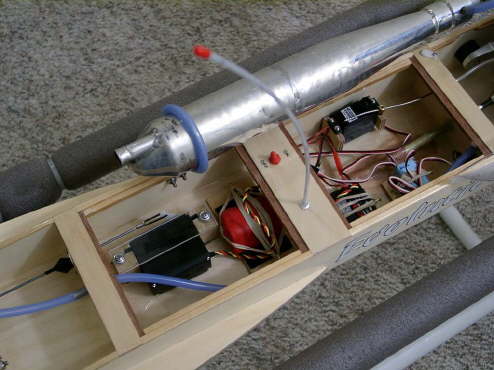

The Evolution boat is a work of art. The woodwork and craftsmanship is top notch. The tub was nicely detailed and perfectly aligned and straight. The sponsons, both front and back, were beautifully made, with nice sharp edges along the running surfaces and smooth curves and joints on the top deck and nose areas. I examined the boat closely for any errors, or mistakes in the wood work, but none could be found. Flawless! The engine canopy is custom made from fiberglass and reinforced with carbon fiber. I told Frank what type of motor I was planning on putting in the boat (Toxic Marine Venom Zenoah 260) and he cut the hatch to match it perfectly. The motor mounts were pre installed and they were already matched up with the stuffing tube. The stuffing tube was installed and reinforced by a piece of carbon fiber on the bottom of the hull.

Frank also uses a unique method to provide carb protection from water spray. He mounts a SIG 10 " plastic airplane canopy on the side of the hull. This canopy works well to prevent the motor from ingesting water and it also allows access to the carb so it can be choked, if necessary. Unfortunately, the only down side to the canopy carb cover is it's durability. If you flip or stuff the boat hard, there is a possibility that the water force will break or tear the canopy, so it is recommended that a few spares be kept on hand. I ended up going through several canopies (indicates how rough I was on the boat as I was learning how to drive a rigger!), so I opted to use a Sullivan 6.5 oz bullet shaped fuel tank as my carb cover. (update: I've switched back to using the aircraft cowl instead of the fuel tank. I now mount the cowl using industrial Velcro and it holds very well, but it allows it to give in case of a flip or crash - Rudy)

" plastic airplane canopy on the side of the hull. This canopy works well to prevent the motor from ingesting water and it also allows access to the carb so it can be choked, if necessary. Unfortunately, the only down side to the canopy carb cover is it's durability. If you flip or stuff the boat hard, there is a possibility that the water force will break or tear the canopy, so it is recommended that a few spares be kept on hand. I ended up going through several canopies (indicates how rough I was on the boat as I was learning how to drive a rigger!), so I opted to use a Sullivan 6.5 oz bullet shaped fuel tank as my carb cover. (update: I've switched back to using the aircraft cowl instead of the fuel tank. I now mount the cowl using industrial Velcro and it holds very well, but it allows it to give in case of a flip or crash - Rudy)

The sponsons are attached to the tub using graphite tubes. The tubes attached to the sponsons slide inside the ones affixed to the tub. This allows the width of the boat to be adjusted.

The sponsons are held in place using stainless steel screw clamps (this has been improved and the Evolution boat now comes with very nice screw down collars). The angle of the sponsons is not  adjustable as it is set at basically the optimal angle for the boat. But adjustable sponson angles can be easily accomplished by slotting the sponson boom holes in the tub, and inserting washers under the appropriate boom to lower or raise the angle.

adjustable as it is set at basically the optimal angle for the boat. But adjustable sponson angles can be easily accomplished by slotting the sponson boom holes in the tub, and inserting washers under the appropriate boom to lower or raise the angle.

So how does the boat perform on the water? One word: Outstanding! The boat handles extremely well. It is very fast and very stable. What I'm learning, though, is that with rigger boats the prop and strut setting can tremendously affect the way the boat handles. If the boat hops in the corners, the strut should be raised. If it feels too light and bouncy, the prop is lifting too much or the strut angle is negative.

So how does the boat perform on the water? One word: Outstanding! The boat handles extremely well. It is very fast and very stable. What I'm learning, though, is that with rigger boats the prop and strut setting can tremendously affect the way the boat handles. If the boat hops in the corners, the strut should be raised. If it feels too light and bouncy, the prop is lifting too much or the strut angle is negative.

The boat has no problem turning left (probably due to the left mounted rudder). The boat is a dream to drive and it goes where you point it. It's just a little nerve racking controlling a boat moving so fast!

I have a limited selection of props, but I found that a cut down Prop Shop 7016 3-blade (making it closer to 66mm instead of 70mm) worked the best for me. This prop allowed the boat to run very settled in the water (which is good for heat racing) and with the Toxic Marine engine and Cooper pipe, pushed the boat into the upper 60s (mph). I've heard that Bob Austin has been working with Frank on a modified 7018/3 that pushes the boat into the mid 70s in heat racing trim. I continue to tweak my setup, trying different strut and prop combinations, as well as different tuned pipe lengths. I'm confident that I can have this boat running consistently in the 70s or better, and I'm confident that the boat can easily handle it!

Specifications:

Length: 39-1/2"

Width: 22-3/4"

Weight: 3 lbs., bare, w/o hardware or motor

Cost: $445 + shipping, includes unsealed tub, sponsons, hatch, turn fin, motor mount, servo mount blocks, carb cover, and stuffing tube

Here are some additional pictures of the Evolution rigger:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here's a short video of the Evolution rigger in action:

.mpg file (2.3 MB)

Right-click and choose "Save target as..."

to download the video file.