Misc. Article ...by Brad Mahs

What to do when you find yourself upside-down!

You run R/C boats, and it's going to happen to you. You're going to end up flipping your boat, and there you'll be; boat either submerged to the gunwales, or bow poking up to the heavens, bobbing unceremoniously as a fiberglass or wood testament to your driving skills (or lack thereof!). After the initial shock and anger have subsided, the first question will inevitably be: "Now what?"

Not to worry, In this three-part article, we'll first take you through a few steps to help you retrieve your catch. Then we'll show you how to assess any damage, get it dried out, and hopefully back in the water running again! Finally, we will then backtrack and discuss how you can prevent damage in the future by performing some simple preventative maintenance.

The retrieval

Obviously this will vary considerably depending on where you are running and under what conditions. Here are some different options:

- Wade. If the water is no deeper than thigh or waist high, this is a good way to cool off! If there are drop-offs, currents, or other water hazards (gators for instance), this is a definite no-no! When rescuing our boat in this manner, it is always best to have an observer on the shore for added safety.

- Use a

boat. Size, material, propulsion will vary widely. We're talking anything from a

full-sized pleasure, fishing or pontoon boat, to PWCs

(personal water craft), paddleboats, to 1-man

rubber rafts! The latter can be found at local K-Mart or Wal-Mart stores for

under $50 US.

(personal water craft), paddleboats, to 1-man

rubber rafts! The latter can be found at local K-Mart or Wal-Mart stores for

under $50 US.

- Use a retrieval system. Examples are attaching an object to a string or fishing line (such as a tennis ball) and hand throwing, casting or shooting the object across your stalled boat. The trick here is to snag some appendage on the boat and pull or reel it back into shore. Hopefully, you've attached a sturdy bow hook to make this task easier! If your boat stalls beyond the range of your retrieval system, you're also out of luck, thus requiring the use of a manned boat to retrieve it.

- Use another R/C craft as a retrieval vessel. This one can be fraught with problems (retrieval craft dies going out/coming in; might not handle a capsized boat, etc.), but can show the crowd you're a real tech-head!

Notice that,

in none of the options listed above, is "Swim for it" listed as a viable option!

The only time you should try swimming for your boat, is if you are wearing a

Coast Guard approved PFD (personal floatation device), and there are others

nearby who can swim, in case trouble should arise. It doesn't matter if you're a

3-time Olympic swimming medallist; NEVER try to swim for a stalled boat alone,

or without a PFD!

Notice that,

in none of the options listed above, is "Swim for it" listed as a viable option!

The only time you should try swimming for your boat, is if you are wearing a

Coast Guard approved PFD (personal floatation device), and there are others

nearby who can swim, in case trouble should arise. It doesn't matter if you're a

3-time Olympic swimming medallist; NEVER try to swim for a stalled boat alone,

or without a PFD!

- The risk of being overcome by cramps, hypothermia, fatigue, or getting tangled in weeds and drowning is too great. Also, whenever you're on the water (options 1 or 2), be sure to wear a Coast Guard approved flotation device. Besides being a law in some parts, it's just good solid common safety sense.

- In a race, you will have to wait for the heat to end before you can retrieve your boat; most clubs have a retrieval boat. If you're running on a river, you probably can't rely on option 1, 3 or 4. Some lakes might have limited access, or the water might not be conducive to wading. You have to consider where you are running and plan accordingly. Know the water you test, play or practice in. It could save your boat or more importantly, your life!

- Assessing the damage

- First and foremost, turn off the receiver! A lot of folks forget to do this in the excitement of retrieving the boat. Next, check the radio box for water. Then check your fuel system too. Next , pull the spark plug and see if there is (and how much) water is in the cylinder.

- OK, best case scenario; you drain the water out of the boat, and find no water has entered your radio gear or fuel system (lucky you!). After you have removed the sparkplug, flip the boat upside down and pull the start cord to expel the water from the cylinder. At this point, some people simply re-install the plug, and try starting the motor. If it starts and runs good, typically running the boat will "cook" the remaining water from the system. I prefer to spray WD-40 into the cylinder, flip the boat over again, and pull the cord. Repeat this process several times, until you're satisfied that all water is out of cylinder, crankcase, transfer ports, etc. If possible, spray the coil area with a corrosion prohibitor, such as Corrosion X (more on this stuff later!).

- Dry off

the spark plug electrode, check the plug for any damage, and re-install it in

the engine. If you have access to an air compressor, use it to

blow off any water remaining, and to dry

components. If you run in brackish or saltwater, you may have more work,

cleaning out the cylinder and carburetor, and performing a fresh-water rinse of

all components. This is very important even as a general maintenance step to

prevent serious corrosion on the steel and aluminum components of your boat.

However, if the water was fairly clean, and you've removed it from the cylinder,

go ahead and re-prime the engine and try starting it! It may take a few pulls to

clear out all the water from the carburetor and burn out the WD-40 in the

cylinder. If the engine fires, and all other systems have checked out 100%,

you're back in action! If you don't get a chance to run the boat after you've

retrieved it, I'd recommend re-greasing the drive shaft, especially if the boat

was under water for an extended period of time.

blow off any water remaining, and to dry

components. If you run in brackish or saltwater, you may have more work,

cleaning out the cylinder and carburetor, and performing a fresh-water rinse of

all components. This is very important even as a general maintenance step to

prevent serious corrosion on the steel and aluminum components of your boat.

However, if the water was fairly clean, and you've removed it from the cylinder,

go ahead and re-prime the engine and try starting it! It may take a few pulls to

clear out all the water from the carburetor and burn out the WD-40 in the

cylinder. If the engine fires, and all other systems have checked out 100%,

you're back in action! If you don't get a chance to run the boat after you've

retrieved it, I'd recommend re-greasing the drive shaft, especially if the boat

was under water for an extended period of time.

- Now, if you've taken on water in the radio system, you'll have more work to do. Remove the batteries, dry them off, spray them with Corrosion X, dry them well and replace/recharge them. Unplug everything from the receiver, remove the crystal, and open the receiver case. Dab excess standing water with a clean, soft cloth or paper towel. Spray the circuit board liberally with Corrosion X and dab excess with a towel. Let it sit while you open the servo cases and do the same procedure to their circuit boards. Again, a light blow with compressed air is handy here. Wipe the excess protectant from the components and reassemble the servos and receiver. Prior to re-installing them, now is a good time to re-evaluate your radio box! Take it out and make sure it's watertight. Poke a couple of control rods into the exit points and dunk it in the sink! Seal up any leaks and you'll save yourself an encore of what you just went through. It is less expensive to check and re-check your radio box than it is to keep replacing damaged radio gear.

- If you had any water in your fuel system, dump the contaminated fuel into an approved container and dispose of it properly. It might be safest to dump all of it and refill with a fresh gas/oil mix. This will depend on the type of fuel/vent system you are using.

Once

you've cleaned, dried and corrosion protected everything, install fresh

batteries and fire it up!

Once

you've cleaned, dried and corrosion protected everything, install fresh

batteries and fire it up!

- If you find the engine just won't run, you may have suffered further damage than is visually evident; bent or broken connection rods, piston wrist pins, rings, etc. are not uncommon when an engine ingests water and gets hydraulic locked - trying to compress the unyielding liquid puts tremendous stress on moving parts. An entire teardown and rebuild may be in order. Don't be shocked if it's necessary! Unfortunately, this can be a very costly exercise; if the connecting rod is bent, the whole crank might need to be replaced. The cylinder head can be damaged if the mounting "ears" on the jug are bent due to the force. Often the piston, wrist pin, wrist bearing, crank and cylinder head need to be replaced! Sometimes, it might be cheaper to just buy another motor.

- As a

testament to the ability of Corrosion X to restore electronics and stop the corrosion

process, check out Rudy's "Lost and

Found"

article. He was able to revive his boat after it had spent 8 weeks at

the bottom of the Potomac River! There are other products like CorrosionX that

can save electronics dunked in water as well; Aerotrend's Aeroplate, Corrosion Block, CRC Corrosion Inhibitor,

and other dielectric greases. There are also products such as CRC Marine Heavy

Duty Corrosion Inhibitor, which act as a protective film coating to seal out

moisture.

article. He was able to revive his boat after it had spent 8 weeks at

the bottom of the Potomac River! There are other products like CorrosionX that

can save electronics dunked in water as well; Aerotrend's Aeroplate, Corrosion Block, CRC Corrosion Inhibitor,

and other dielectric greases. There are also products such as CRC Marine Heavy

Duty Corrosion Inhibitor, which act as a protective film coating to seal out

moisture.

- Prevention

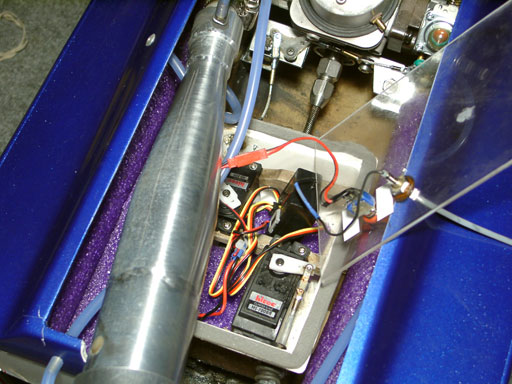

- OK, now that you know what to do should "IT" happen to you, take it to heart and do some preventative maintenance before the first launch of your next new boat. Make sure your radio box is watertight! Spray everything (excluding membrane or keypad type switches) with Corrosion X or similar type product. Keep your receiver dry by spraying it down with Corrosion X, filling it with bees wax or wrapping it in a balloon or condom (yep, that's right). Do the same with batteries. Douse servos with Corrosion X before installing them in the boat. Use good grade radio box seals and keep them well lubricated with silicone or other waterproof lubricant. You can even add water absorbing material to the radio box to help reduce the possibility of the electronic gear getting wet.

- Change your fuel system; try running your vent line up into the bow of the boat. Or use a catch tank for a vent. If you take on water, typically you will only have to dump the water -contaminated fuel from the vent catch tank, versus the entire fuel system. A sealed, bladder type ("IV bag" type) fuel set-up is a blessing! Because it's a totally sealed system, it will typically prevent any water from entering the fuel and it keeps fuel from spilling out contaminating the pond.

Floatation:

This is a tricky subject, and opinions differ greatly. The bottom line is; use

plenty of floatation that will not absorb water, and is not affected by gas or

oil. Good options are pool "fun" noodles, 2 liter rigid plastic pop bottles

(glue the caps on), some 2-part or partially expanding pourable/spray foams

(avoid the "Great Stuff" foam found at hardware stores, it soaks up a lot of

water), partially inflated beach balls, and many other forms of foam flotation.

Be sure to attach the floatation securely. You don't want your floatation

bobbing around by itself, while your boat becomes a submarine! If you run with a

hatch on, be sure to add some floatation to it as well.

Floatation:

This is a tricky subject, and opinions differ greatly. The bottom line is; use

plenty of floatation that will not absorb water, and is not affected by gas or

oil. Good options are pool "fun" noodles, 2 liter rigid plastic pop bottles

(glue the caps on), some 2-part or partially expanding pourable/spray foams

(avoid the "Great Stuff" foam found at hardware stores, it soaks up a lot of

water), partially inflated beach balls, and many other forms of foam flotation.

Be sure to attach the floatation securely. You don't want your floatation

bobbing around by itself, while your boat becomes a submarine! If you run with a

hatch on, be sure to add some floatation to it as well.

- Many racers use just enough floatation to keep the deck above water, in an attempt to create less of a "target" for other racers. Some run with open drain holes in the transom, and open vent holes in the bow. If they flip or roll, the hull will take on water, partially sinking the boat. If they do get hit while stalled, they don't end up getting t-boned in the gunwale; instead, they might end up with a few prop marks on the deck!

- By all means, test your floatation! Secure rocks or other weight in the hull to simulate the engine weight/location, and radio gear position/weight. Better yet, do a full dunk test, with radio box, motor and all. Flood the entire boat right side up (so air doesn't get caught in the hull), and see if it floats. Yes, water may get into the motor when you do this, but it will anyway when you first flip the boat, so why not try it when you can observe it easily? Put the hull in a pool or shallow pond area. Roll the boat over by hand and observe what happens. Try it with and without the hatch on. There is no gray area here: if it doesn't float well, ADD MORE FLOATATION! Better to be safe than sorry!

- Also periodically check your floatation throughout the season, and from season to season. If anything is loose, or has absorbed fuel/oil or water, replace it. It's a good idea to replace pool "fun" noodles each season. If bottles, bags or balls have holes or appear distressed, replace them! Again, an ounce of prevention will likely save you hundreds (if not thousands) of $$$!!!

- In all of these scenarios, remember to take some extra time before storing the boat for the next outing. Go over everything, tightening and checking all systems again. It's also a good idea to re-wax the running gear. This will prevent corrosion from occurring. Just don't wax the prop!

- Flipping the boat is quite common, and if you take preventative action, you should be able to fill the boat with water several times in a day and keep running. Hopefully, by planning ahead, keeping a cool mind and being thorough, you'll have less work to do next time you "deep six" your boat!