How-to Article ...

Learn how to make a "stubby" spark plug to fit under tight cowls...

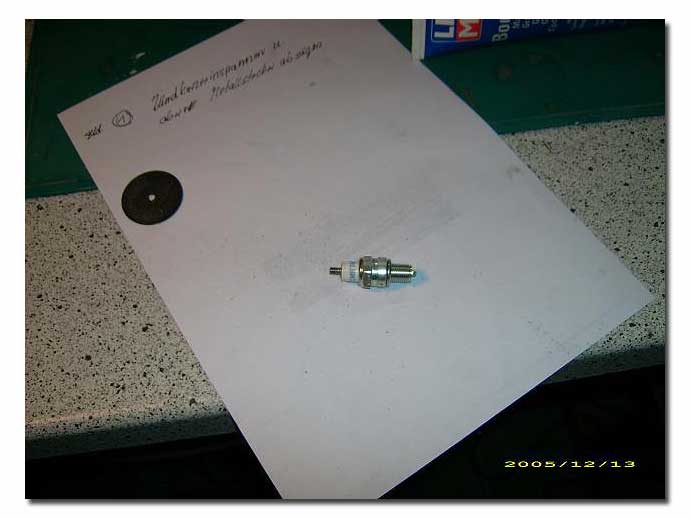

During the planning of my next project I found out that it would be better to have some shorter spark plugs so that it would not be necessary to cut the hatch of the boat. I remembered that my buddy Jochen had this problem before so I gave him a call and asked him what to do.

He told me that he shortened a stock spark plug from NGK. Now he had my attention and I asked him if he could make me some of them.

A few days later I found 4 shortened spark plugs in my mail. They looked so good that I asked Jochen to take some pictures and explain the process.

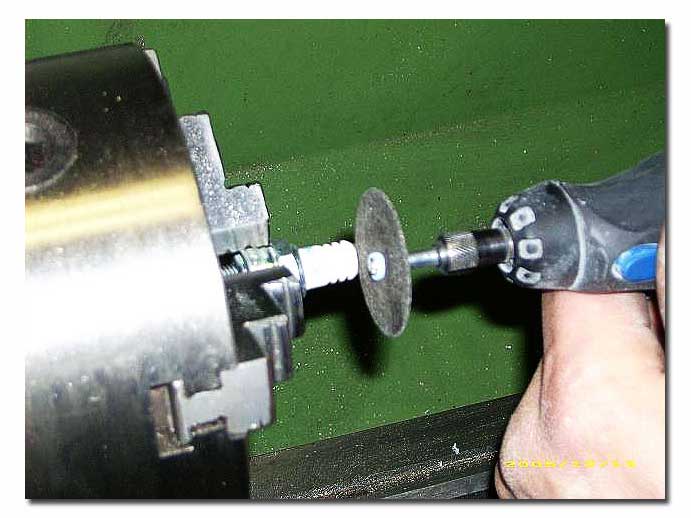

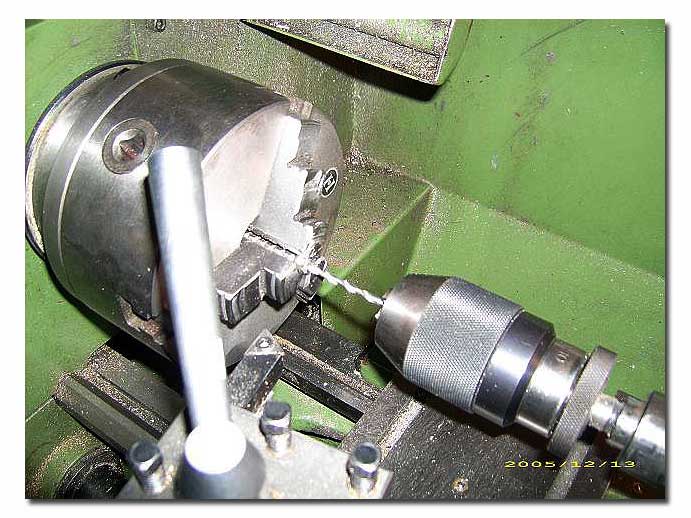

Jochen starts by cutting the cap (connector) using a Dremel. It is better to mount the spark plug in the chuck of a lathe, but it can also be done without. He cuts the cap close to the ceramic isolator. Make sure that you don’t lose it or chuck it away, you need it later!

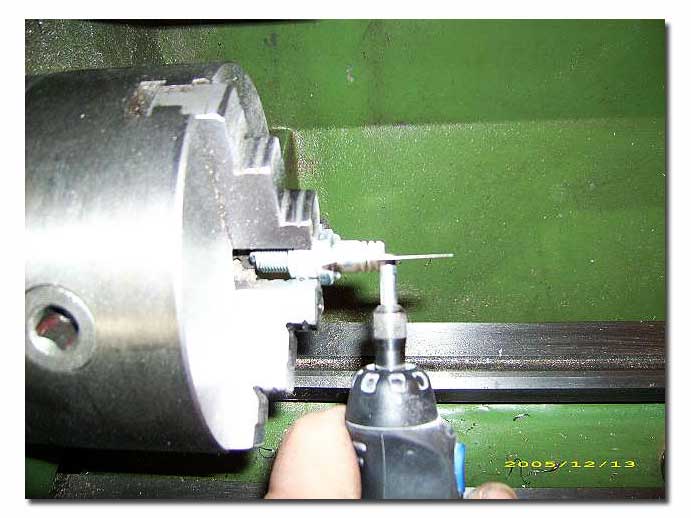

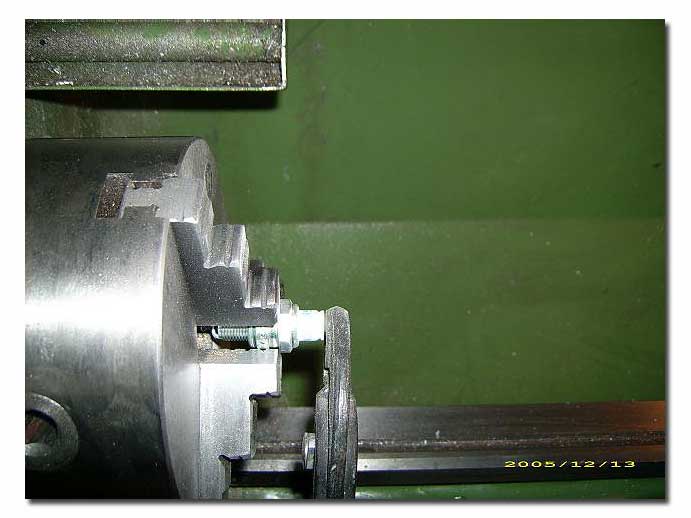

After that he cuts the ceramic isolator with the Dremel up to the metal rod inside. This takes some time because the ceramic is very hard. Wearing a mask during this work is strictly recommended! When scratching the metal inside the isolator he cuts a small slot along the isolator part that is to be removed. Now it is possible to remove the cut isolator part from the plug with a pair of pliers.

***Please note: a diamond cutting wheel is required to cut the ceramic.

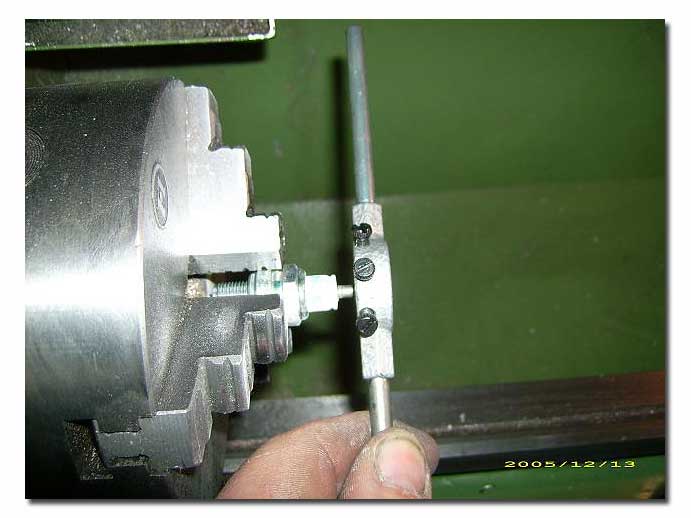

The now exposed metal rod is then threaded with a die. To fit the original contact on the top Jochen drills a small hole inside the cut cap and taps threads inside to match the threaded rod. So it is easy to install the original cap to the just shortened spark plug.

Using the lathe for the shortening is not strictly necessary. It works also to use a cordless screwdriver or a drilling machine and a vise.