How-To Article ...by Patrik Tegelberg

Learn how to make this automatic water bailer that works without any moving parts!

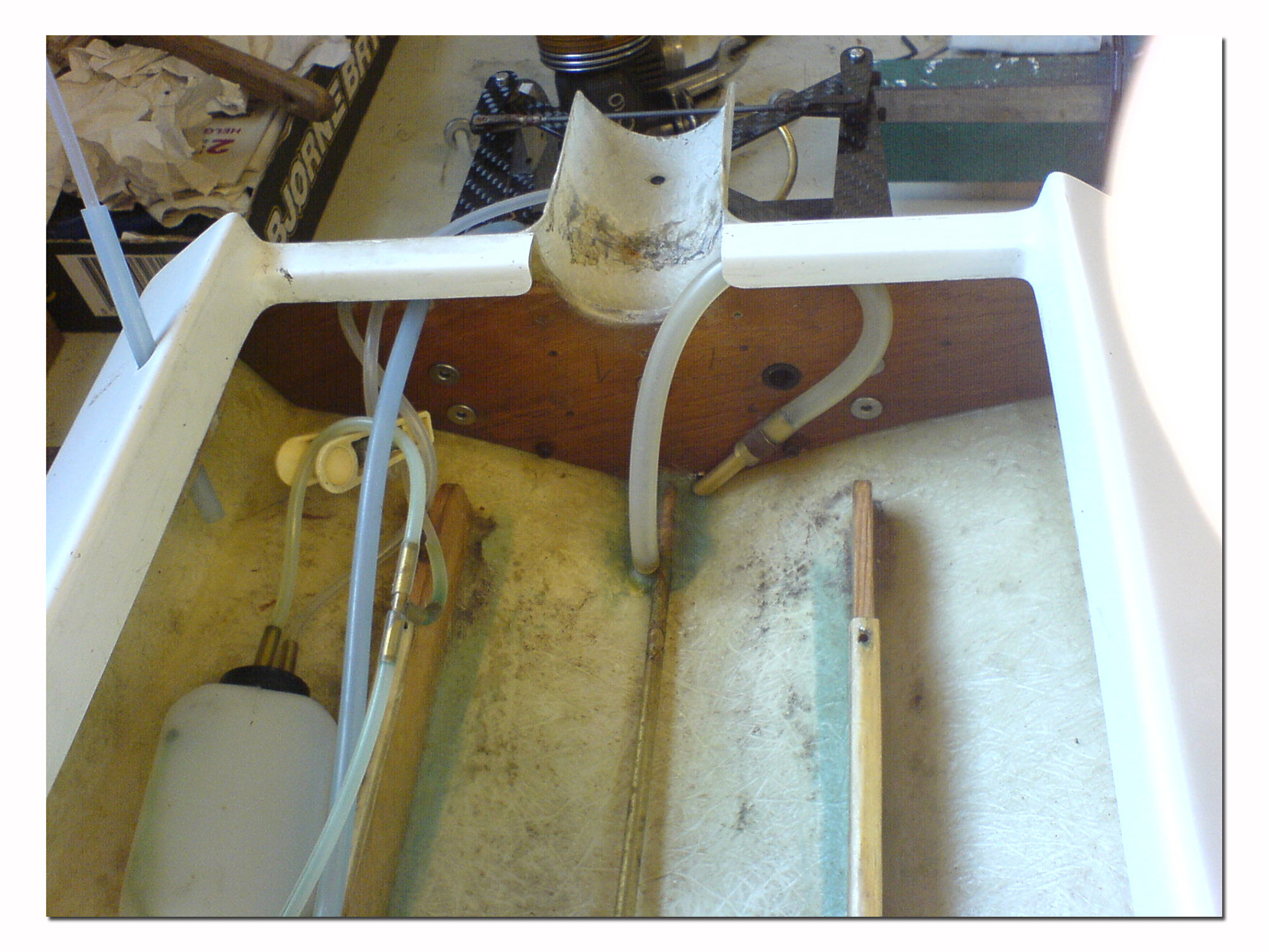

Here will describe a water bailer that can readily be made by everyone using easily available and inexpensive hardware. One only needs a short length of brass tubing and a short matching hose (silicone tubing). The end result is no more complicated than can be seen in picture 1 as the loop in the stern.

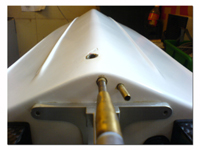

Picture 1. The

looped hose in the stern is a Bernoulli water bailer.

Picture 1. The

looped hose in the stern is a Bernoulli water bailer.

I call the water bailer a Bernoulli(1) water bailer because it utilizes a principle that is called the Bernoulli principle.(2)

V2 / 2 + g * h + p / r = constant

...states that as the velocity (v) increases, the pressure (p) decreases. So if we have access to high velocities, which we hopefully have, we can potentially have access to low pressures i.e. suction.

The loop in picture 1 leads from a pickup tube (placed where the water is expected to be) to a hole in the bottom of the hull outside which the water passes at high velocity and thus creating the suction needed to transport the water from the inside to the outside. The loop of the hose is such that its highest point is above the waterline when the boat is at rest in the water. This creates a barrier to stop the water from flowing back into the hull in case of a stop. If the water were to reach around the loop it would become a siphon and the boat would fill up with water. To prevent this from happening in case of a wave or other disturbance hitting the boat, there should be a sufficient margin from the highest point of the loop to the waterline; but keep in mind also that the higher the loop the more suction is needed to start the bailing.

When the boat comes to a stop the water rushes forward leaving the pickup dry to clear the hose of water to prevent the siphon to start immediately, or that is the theory and it has worked for me so far. When the boat is accelerating the water is rushing to the stern and is climbing up the transom to reduce the water column height needed to overcome to get bailing started, this works to our advantage and it is wise to place the pickup accordingly, that is far back close to the transom. I have used 5 mm inner diameter tube and hose. To get some real throughput the hose must not be too small.

The trickiest part is to place and shape the hole in the bottom. It should be shaped kind of like a reversed water pickup with a small ramp in the front and a smooth aft edge. The thing that must not happen is that the water hit the aft wall and start pushing up into the boat. Also for this to work the hole must be surrounded by water so it must be some distance from the transom so that the water coming off the ramp has time to reconnect with the bottom of the hull before the transom. I put my hole about 4 cm (approx. 1.5 inches) forward of the transom as can be seen in pictures 2,3 and 4.

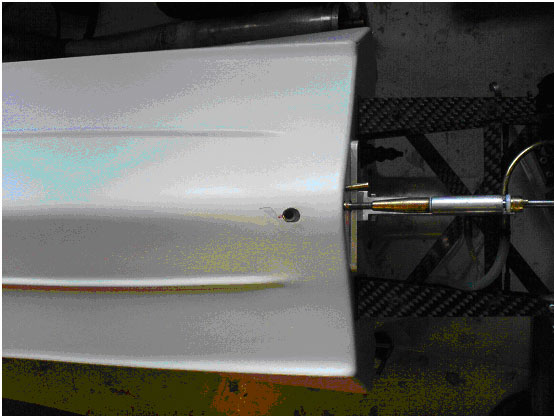

Picture 2. Hole

placement of drain.

Picture 2. Hole

placement of drain.

Picture 3. The

brass tube is folded to yield a ramp, some tough putty would suffice to. The

chip in the gel coat is not part of the construction.

Picture 3. The

brass tube is folded to yield a ramp, some tough putty would suffice to. The

chip in the gel coat is not part of the construction.

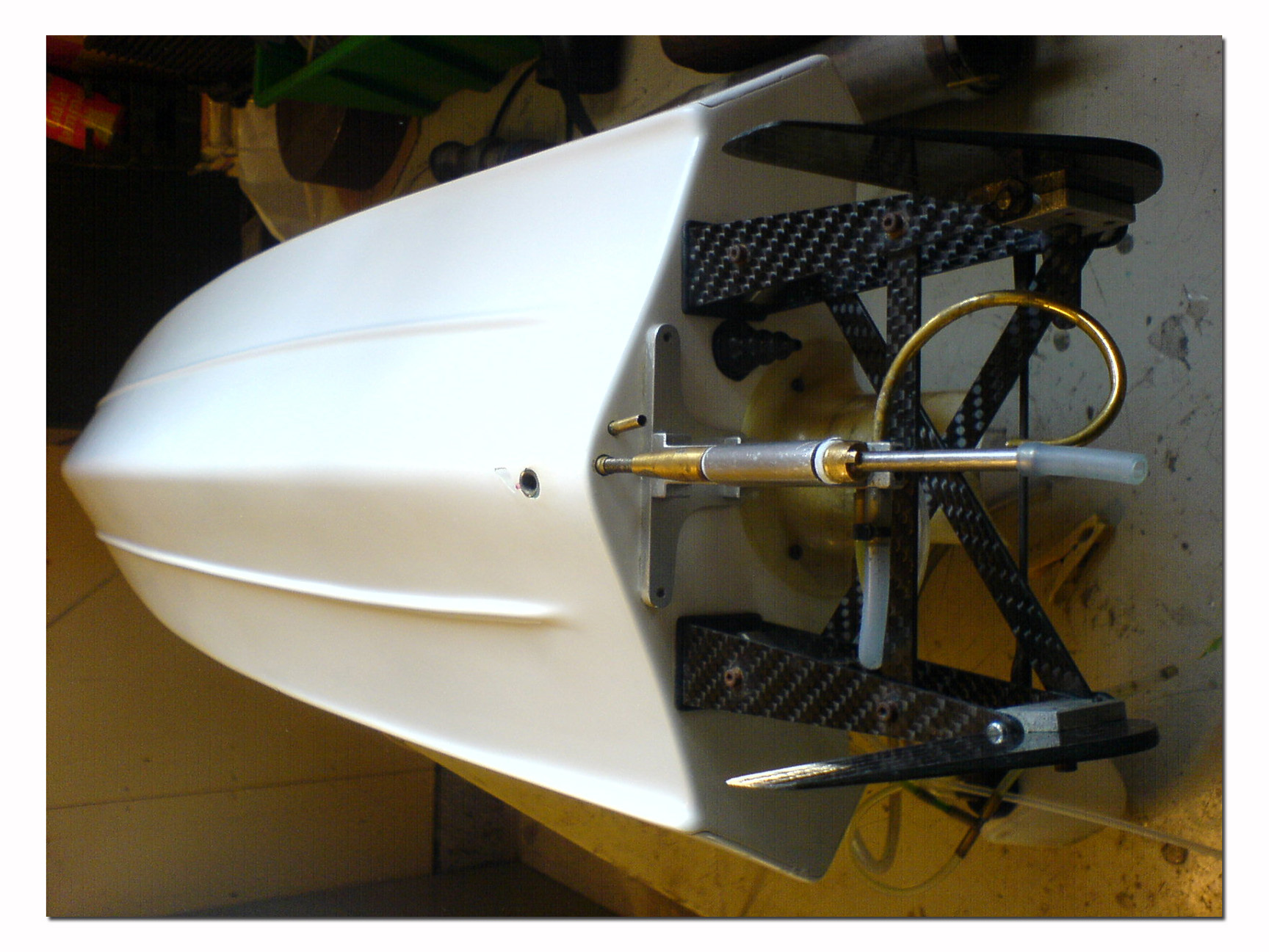

Picture 4. The

smaller brass tube is just a dummy drain used in the pit.

Picture 4. The

smaller brass tube is just a dummy drain used in the pit.

The no moving parts character of this bailer renders it a very low maintenance unit. As a conclusion it can be said that I needed a bailer for my boat and this delivered a shipshape solution!

(1) http://en.wikipedia.org/wiki/Daniel_Bernoulli

(2) http://en.wikipedia.org/wiki/Bernoulli's_principle