Hobby Machinist Article ...

Learn how to make a big bore carb...

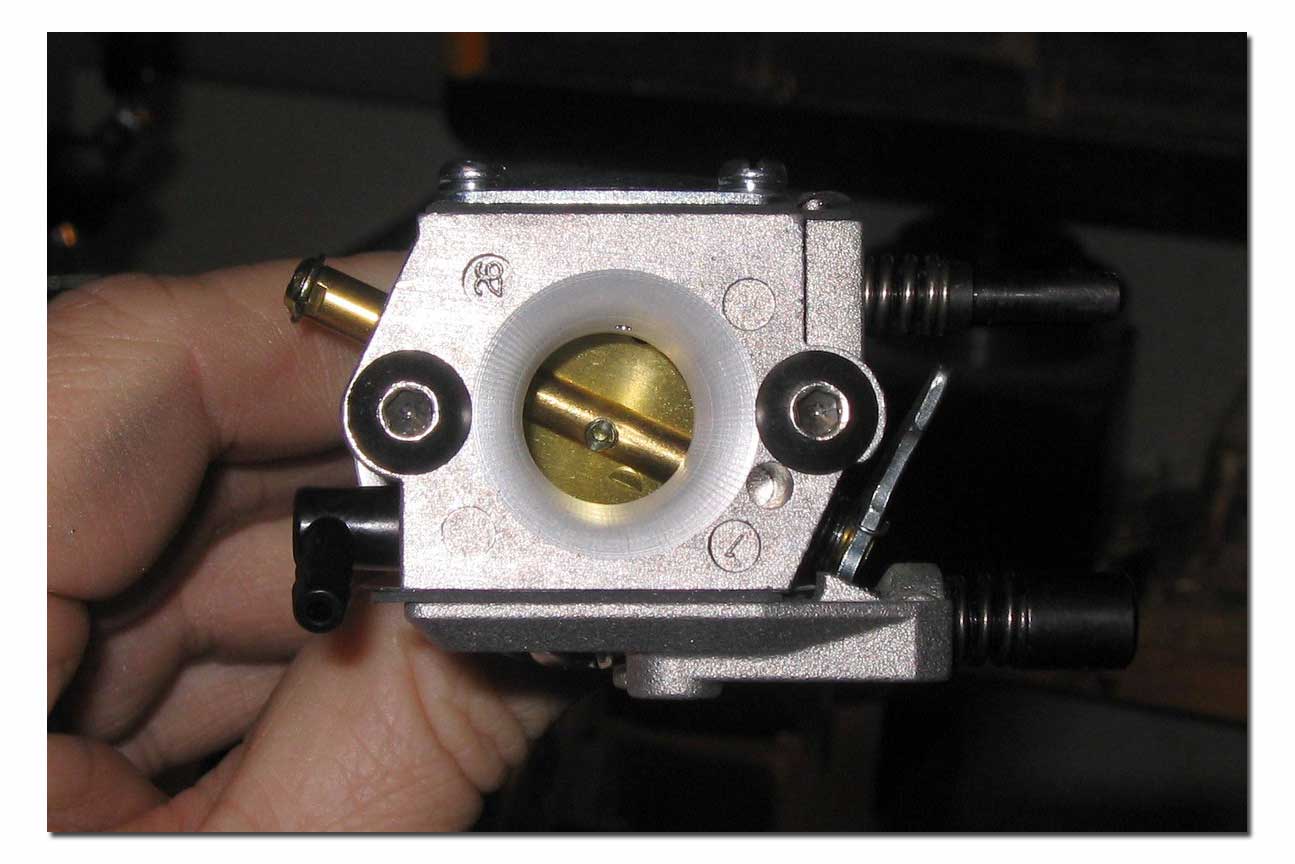

Last year, Matthew Waldron of M&D Racing visited the Xtreme RC Boats club in the Netherlands. It was a nice meeting him and we had a great time together with some more friends that weekend. Matthew demonstrated some of his “speed secrets” and we all listened well to learn our lessons. At this time I was not familiar with grinding and modifying an engine with a Dremel but I was very interested in modifying the WT257 carburetor. Matthew showed me one of his carburetors and by listening him I decided to try it.

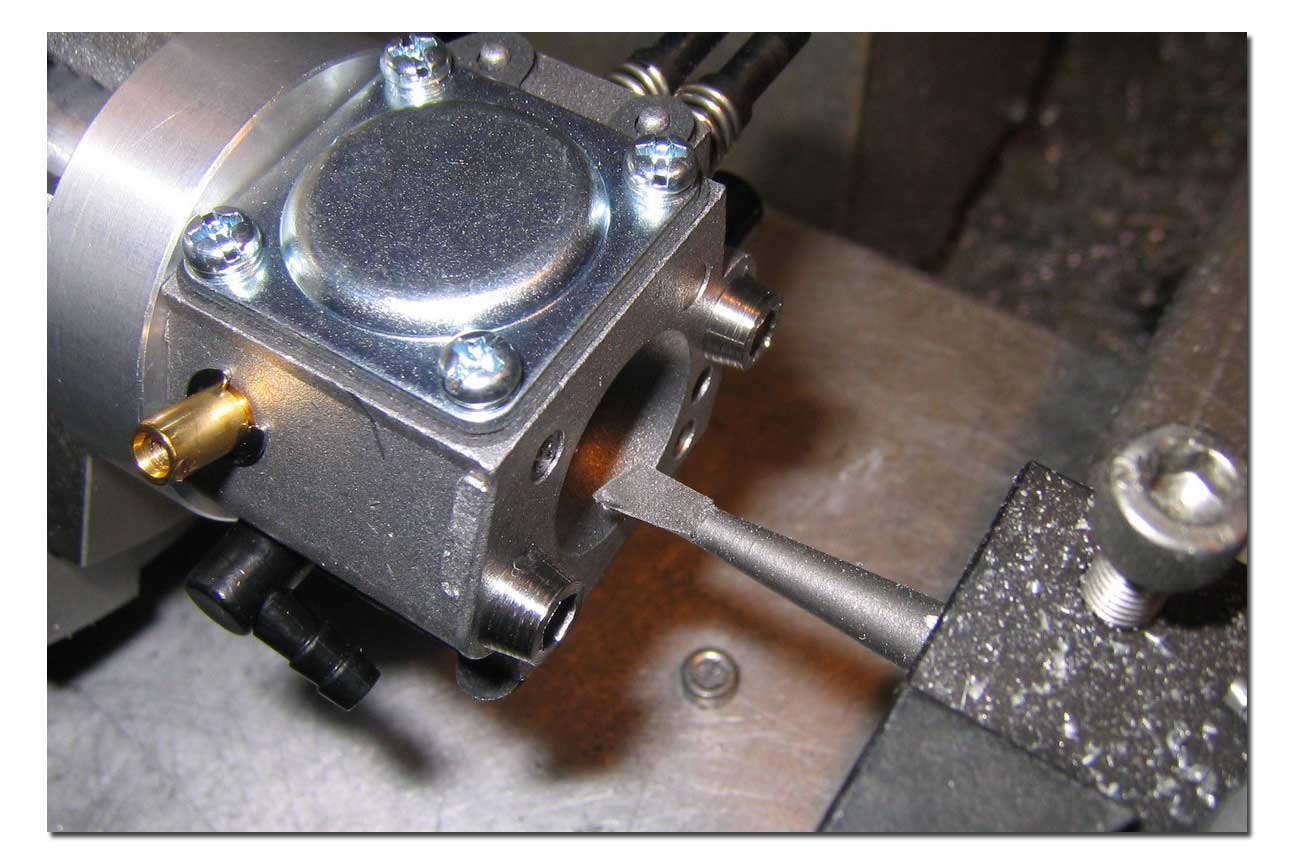

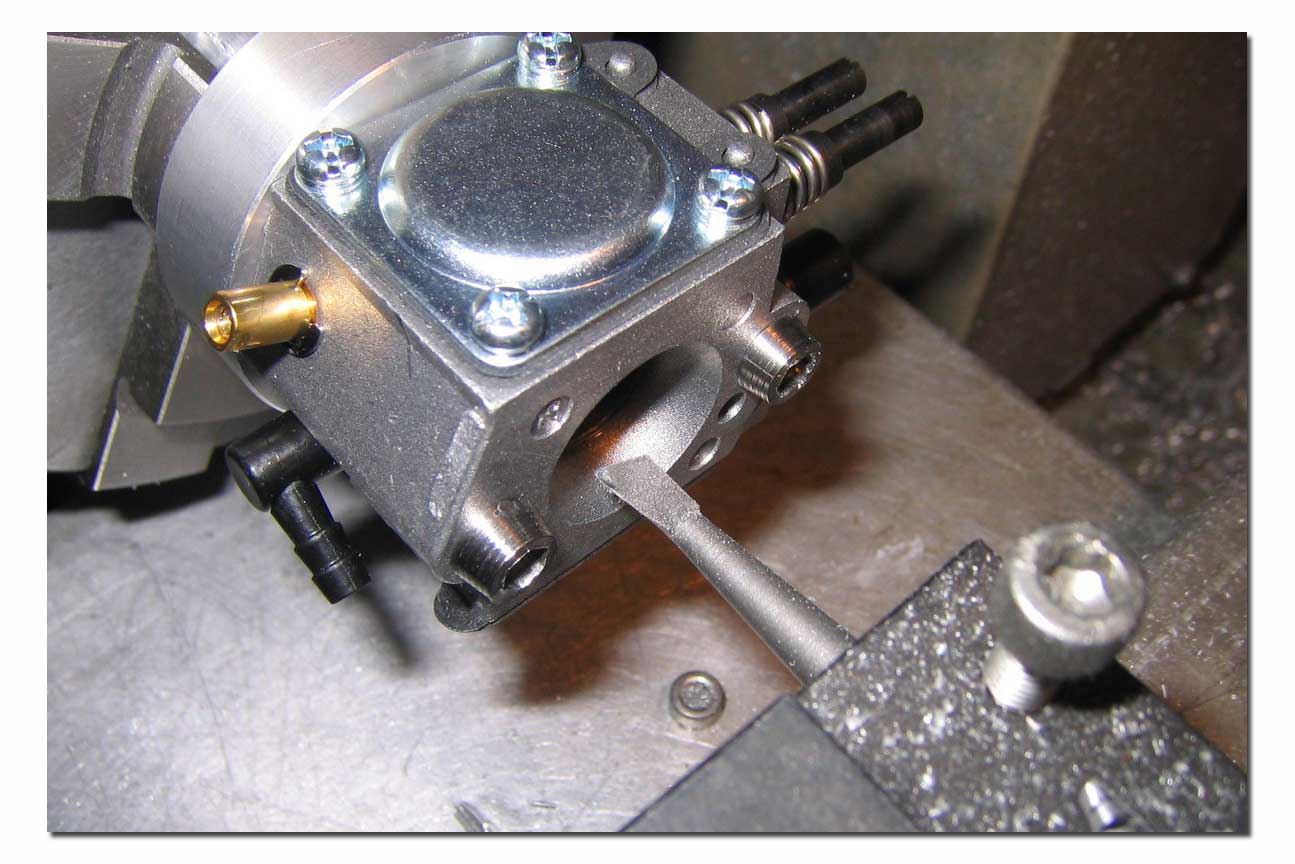

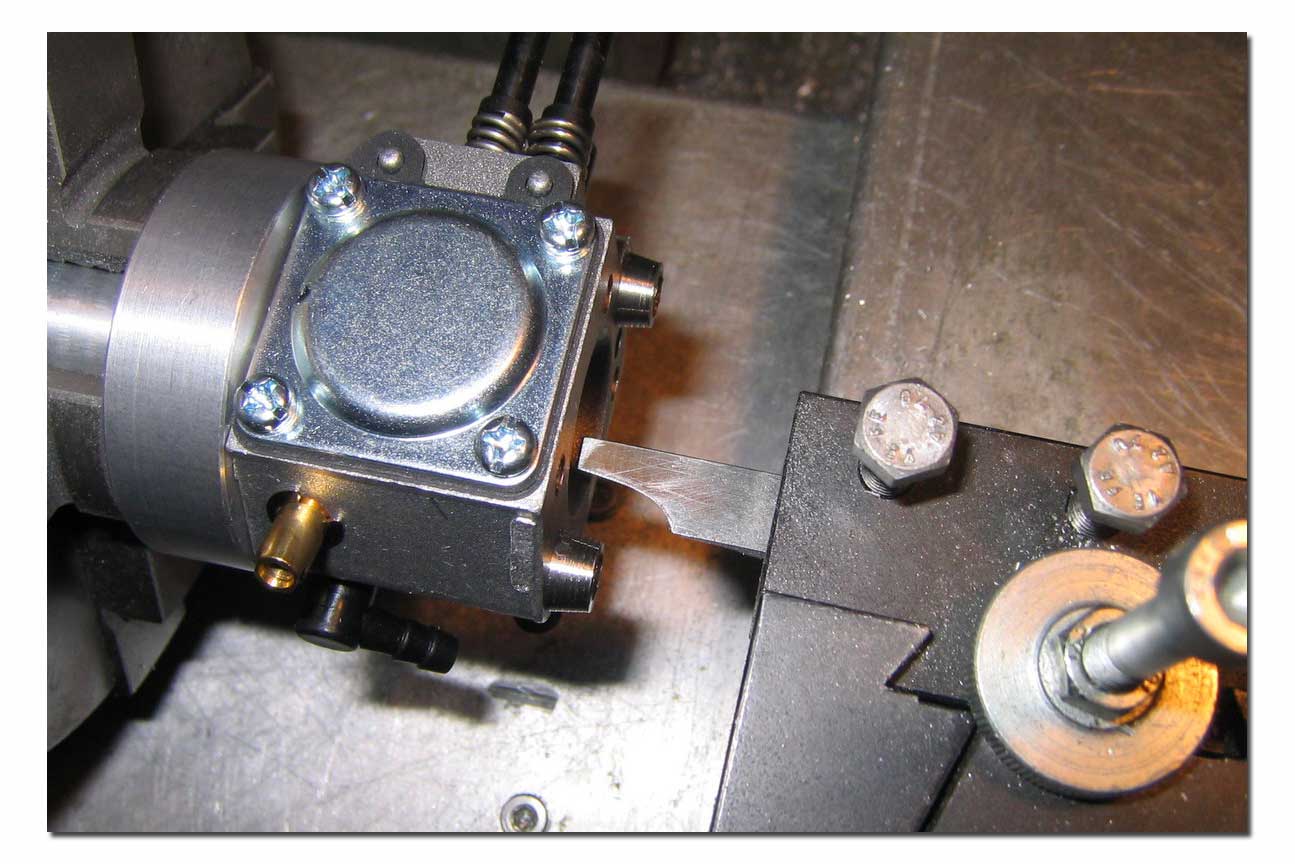

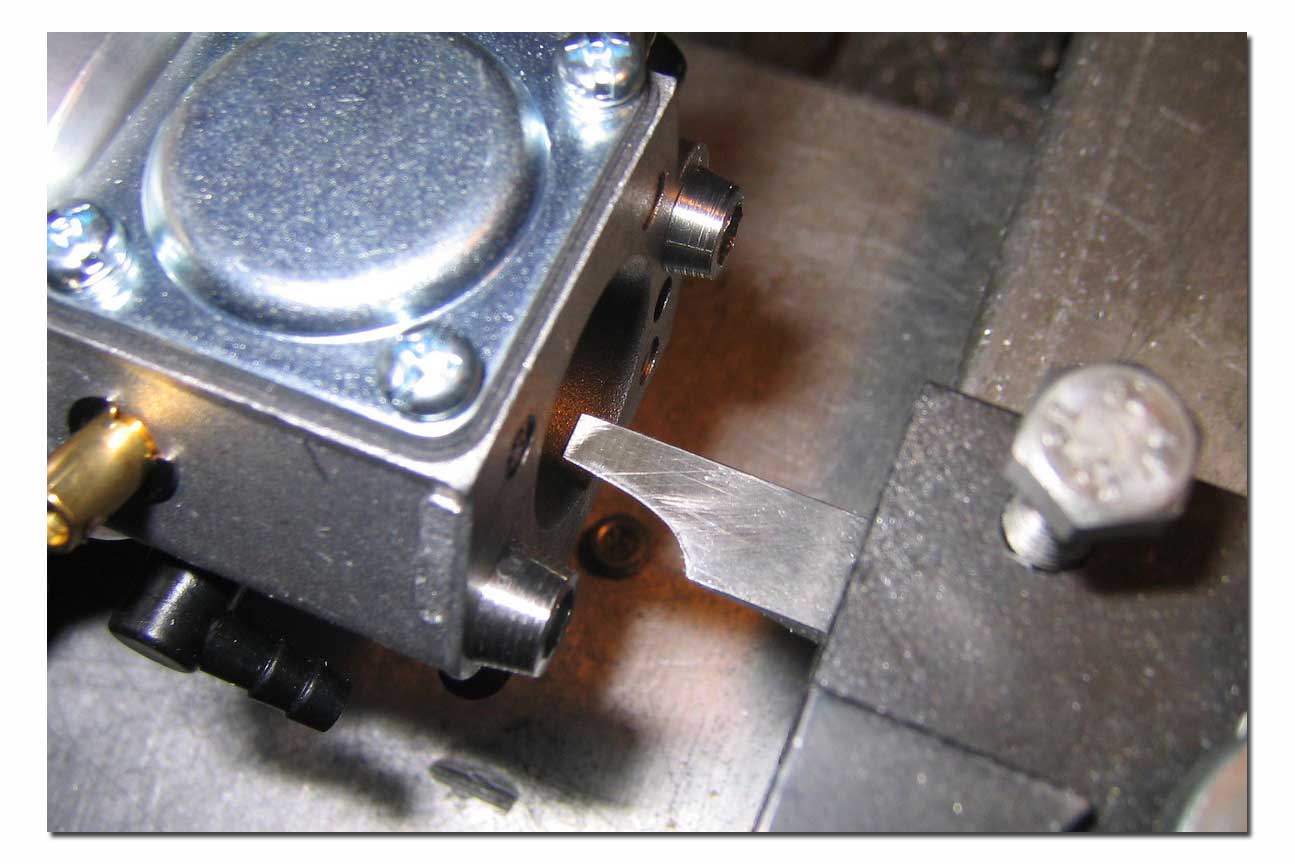

First thing was to make a mandrel for the lathe. I made it from a solid aluminum round bar. I flattened the ends and added a small step (as an alignment for centering the carburetor) with the same diameter of the inside bore of the WT257 carburetor. After drilling two holes and taping threads for the fixing bolts the mandrel was ready.

I opened the intake of the first carburetors from 0.500’’ to 0.540’’ with a turning tool.

By using this turning tool it is not necessary to dismantle the butterfly. After that I used to shape the bell (rounded intake of the carburetor) by using a cutter with my hands. It worked but I was not satisfied. So I decided to grind a special turning tool. This tool has the exact form of the bell and so it is easy to get repeatable results.

After finishing the bell I clean the carburetor with the air gun. This job has to be done very carefully so that there is no dust inside the small injector hole. For installing the carburetor to the engine I use flathead screws.