piston pin spacer's help

unclecrash created the topic: piston pin spacer's help

Wondering is the little lip suppose to face the needle bearing, seems to fit over the bearing nice, but the end play from piston boss spacer when installed is huge. what should the free play be I believe around .008 to .012 Also which of the spacer's are the biggest the zen or rcmk Thanks Dave

Please Log in or Create an account to join the conversation.

- unclecrash

- Offline

- Posts: 11

- Thank you received: 0

strictlybusiness1 replied the topic: piston pin spacer's help

Yes, the little lip should face the needle bearing. In set ups that use modified Bi-Zeta connecting rods, the thrust washers are machined down to give a total clearance of .003" to .005". These setups use an oversize crank pin (.3942) with the bottom end radial clearance reduced to .0003" to .0005". The bottom end axial clearance is set at .010" to .015" which means the rod is guided in the upper end where the rotational speed is much lower. No failures or problems with 10 ounces of HP-2/ gal at RPM's of 22,000+. A crankcase that is square make this easily possible.

Setups made with custom connecting rods use no needle bearing assemblies & no thrust washers. Some have bushings & some run with the wrist pin directly on the connecting rod material without any bushing. All rods types are double slotted in the bottom & single slotted in the top for adequate lubrication. Rods that are designed without needle bearings & thrust washers give a great weight saving in the upper end! No needle bearing used can be designed to carry the load of a bushing!

Jim Allen

Setups made with custom connecting rods use no needle bearing assemblies & no thrust washers. Some have bushings & some run with the wrist pin directly on the connecting rod material without any bushing. All rods types are double slotted in the bottom & single slotted in the top for adequate lubrication. Rods that are designed without needle bearings & thrust washers give a great weight saving in the upper end! No needle bearing used can be designed to carry the load of a bushing!

Jim Allen

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

earthsurfer replied the topic: piston pin spacer's help

Yea---what Jim Allen said!!

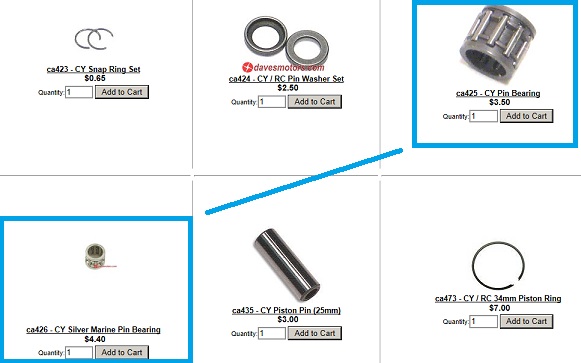

But to add, generally speaking, you should use the bearing and washers that come with the piston (or made for that piston). I found the 36mm RCMK and Zenoah pistons can share the Zenoah bearing and washers and even the ring. But the CY bearing is 1mm wider than Zens, the CY washers are thicker than Zens also, so the CY piston "gap" is wider than Zens (usually, a Zen piston will not slip over the longer and wider CY parts). So if you use a Zen bearing and washers on a CY piston, you will get quite a bit of side to side play at the top rod end. I am sure many have used the short top rod parts on a CY piston, but I have never seen a failure because of it (not to justify using the wrong parts for the piston). The "rod end width" is the same for the Zen and CY cranks, so you don't have to worry about that factor. I know this from the air cooled engines (I never worked with CY marine), which may have more opportunity to "mix up the parts" than the marine application. I have never seen the 4-bolt CY engines (air cooled or marine), but I assume, with great confidence, they are a copy of the 2-bolts for the inner parts.

Doug @ ESP

But to add, generally speaking, you should use the bearing and washers that come with the piston (or made for that piston). I found the 36mm RCMK and Zenoah pistons can share the Zenoah bearing and washers and even the ring. But the CY bearing is 1mm wider than Zens, the CY washers are thicker than Zens also, so the CY piston "gap" is wider than Zens (usually, a Zen piston will not slip over the longer and wider CY parts). So if you use a Zen bearing and washers on a CY piston, you will get quite a bit of side to side play at the top rod end. I am sure many have used the short top rod parts on a CY piston, but I have never seen a failure because of it (not to justify using the wrong parts for the piston). The "rod end width" is the same for the Zen and CY cranks, so you don't have to worry about that factor. I know this from the air cooled engines (I never worked with CY marine), which may have more opportunity to "mix up the parts" than the marine application. I have never seen the 4-bolt CY engines (air cooled or marine), but I assume, with great confidence, they are a copy of the 2-bolts for the inner parts.

Doug @ ESP

Last edit: 12 years 5 months ago by earthsurfer.

Please Log in or Create an account to join the conversation.

- earthsurfer

-

unclecrash replied the topic: piston pin spacer's help

Thank's Jim I have been reading some of you article's and only wish I had the equipment to do the mod's on the bearing,but am limited to a small jet mill which I need to get some the spindle's and cutting bit's for. It would be nice to see someone market these type's of bushing and part's so the average guy who cannot afford the machine's and tooling could use these part's to his advantage. Thank's Dave

Please Log in or Create an account to join the conversation.

- unclecrash

- Offline

- Posts: 11

- Thank you received: 0

unclecrash replied the topic: piston pin spacer's help

I am using a modded rev piston with a zen crank piston pin is zen and I think the needle bearing is rev not sure need to check. I did not know the part's would not work properly. So I might wind up getting a zen piston and part's.

Please Log in or Create an account to join the conversation.

- unclecrash

- Offline

- Posts: 11

- Thank you received: 0

whitefish replied the topic: piston pin spacer's help

If you are subscribed to JRCBD, please see thread titled:

"Rev Unlimited - New motor review only......."

Reply number 160.

My understanding is that Rev Unlimited uses an extra long wrist pin

bearing with no washers (cups).

Since you have a Rev piston, could this explain the differences?

______________________________________

Here is a pic showing the difference in the length of the three common

wrist pin bearings.

I think the CY wrist pin bearings are the same as the RCMK's length but

not being certain, I did not label this pic as such. If anyon is certain,

please let me know.

"Rev Unlimited - New motor review only......."

Reply number 160.

My understanding is that Rev Unlimited uses an extra long wrist pin

bearing with no washers (cups).

Since you have a Rev piston, could this explain the differences?

______________________________________

Here is a pic showing the difference in the length of the three common

wrist pin bearings.

I think the CY wrist pin bearings are the same as the RCMK's length but

not being certain, I did not label this pic as such. If anyon is certain,

please let me know.

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

whitefish replied the topic: piston pin spacer's help

Since we are talking wrist pins and such, here is some CY minutia that fits here

also. CY makes one wrist pin bearing for air-cooled and a different wrist pin

bearing for water-cooled.

________________

Does either Zen or RCMK do this as well or are all of their motors fitted with

the same wrist pin bearings?

also. CY makes one wrist pin bearing for air-cooled and a different wrist pin

bearing for water-cooled.

________________

Does either Zen or RCMK do this as well or are all of their motors fitted with

the same wrist pin bearings?

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

unclecrash replied the topic: piston pin spacer's help

Thank's for the reply I have just got the REV needle bearing and it has about .067 end play between the bosse's then the rod can travel from one end to the other with nothing to contain it. I have got the reply over on Jim's to get the REV bearing so I did, But I thought the whole Idea behind the spacer's was to control the rod side to side on the top in order to keep it centered on the bottom bearing. Or just throw it together with the rev bearing and hope all's well that end's well or something like that. I will check again on the end play on the wrist pin. I was basing this knowledge of of how scott set's up the rcmk in the porting article with using the zen spacer's and sanding them to get his end play. I guess this can't happen on the rev piston. The needle bearing is so long even if you tryed to sand down the spacer's to fit you could get the end play but the lips on the spacer would be useless in keeping the rod from floating all over being the rev bearing it too long. Zen and rcmk both make there own needle bearing's and spacer's is all I know. I don't know if the bearing and wrist pin's are swap able Thank's Dave

Please Log in or Create an account to join the conversation.

- unclecrash

- Offline

- Posts: 11

- Thank you received: 0

whitefish replied the topic: piston pin spacer's help

This is the only instance I can remember where a Rev Unlim piston is being fitted

to a Zen crank. Maybe others have already done this but I don't remember reading

the details of how they got it to work.

If the following is true:

- the Rev wrist pin bearing is the longest ever made for these size engines

- the Rev wrist pin bearing inserts between the piston bosses with no washers

then isn't it logical that Rev has made the top of their piston wider to work with

the wider wrist pin bearing?

Maybe this would be easier if a Rev crank was test fitted with the other parts.

The price is right and many have reported the quality makes them a good value.

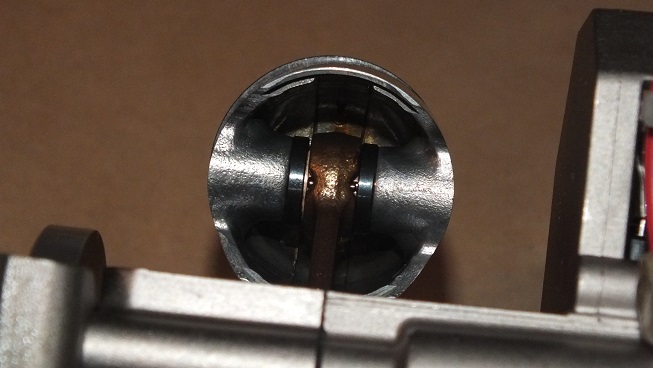

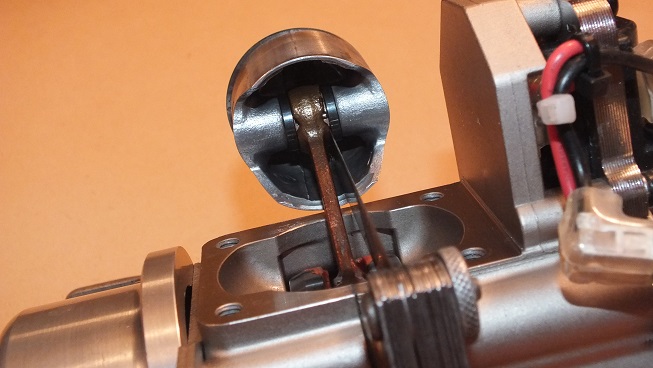

The pic included probably will not help much but it will provide a visual comparison.

This is an "Up Piston" view of a CY F273. Since I pushed the piston to the left just

before I took it, you may be able to see a tiny gap (wrist pin bearing endplay) on the

left side. That gap measures 0.014 inch - when the wrist pin sits in the center of the

available space there is about 0.007 inch space on both sides. I'm not suggesting your

setup needs to be the same - just that it won't differ a large amount.

My understanding is you will need something similar in your setup or there will be

insufficient con rod guidance - a con rod and it's wrist pin bearing dancing back and

forth along it's wrist pin due to a significantly larger gap is going to have problems.

to a Zen crank. Maybe others have already done this but I don't remember reading

the details of how they got it to work.

If the following is true:

- the Rev wrist pin bearing is the longest ever made for these size engines

- the Rev wrist pin bearing inserts between the piston bosses with no washers

then isn't it logical that Rev has made the top of their piston wider to work with

the wider wrist pin bearing?

Maybe this would be easier if a Rev crank was test fitted with the other parts.

The price is right and many have reported the quality makes them a good value.

The pic included probably will not help much but it will provide a visual comparison.

This is an "Up Piston" view of a CY F273. Since I pushed the piston to the left just

before I took it, you may be able to see a tiny gap (wrist pin bearing endplay) on the

left side. That gap measures 0.014 inch - when the wrist pin sits in the center of the

available space there is about 0.007 inch space on both sides. I'm not suggesting your

setup needs to be the same - just that it won't differ a large amount.

My understanding is you will need something similar in your setup or there will be

insufficient con rod guidance - a con rod and it's wrist pin bearing dancing back and

forth along it's wrist pin due to a significantly larger gap is going to have problems.

Please Log in or Create an account to join the conversation.

- whitefish

- Offline

- Posts: 155

- Karma: 2

- Thank you received: 25

strictlybusiness1 replied the topic: piston pin spacer's help

.014 total axial wrist pin clearance is a very large amount for a high RPM 30 cc engine. This would mean that there needs to be .024" to .029" total axial clearance in the bottom end to ensure that the connecting rod is guided only in the top end. Large axial clearances such as these are not desirable for roller assemblies designed to carry only radial loads! Large clearances at both the top & bottom connecting rod ends will require large crankshaft end play amounts.

Large axial movement of the connecting rod & the crankshaft CANNOT be tolerated in a high RPM engine!

Jim Allen

Large axial movement of the connecting rod & the crankshaft CANNOT be tolerated in a high RPM engine!

Jim Allen

Please Log in or Create an account to join the conversation.

- strictlybusiness1

-

Time to create page: 0.108 seconds