Zenoah throttle linkage solutions

Brcaward created the topic: Zenoah throttle linkage solutions

Dear ed

Has MGB got a view about the best (positive, responsive, reliable, durable) push-rod to throttle arm setup for zenoah/walbro carbs? I've tried cable and bell crank variations but nothing seems responsive and or robust enough. Is the speed master linkage as good as it gets? Regards. Brian

Has MGB got a view about the best (positive, responsive, reliable, durable) push-rod to throttle arm setup for zenoah/walbro carbs? I've tried cable and bell crank variations but nothing seems responsive and or robust enough. Is the speed master linkage as good as it gets? Regards. Brian

Please Log in or Create an account to join the conversation.

- Brcaward

- Offline

- Posts: 13

- Thank you received: 0

Ronald Olson replied the topic: Re: Zenoah throttle linkage solutions

I can't complain about the Speedmaster throttle linkage as it works well on all of my gas boats. I have no idea of what the problem is with the other ones, maybe it's because I haven't tried them. "As good as it gets?". Maybe, until a better mousetrap comes along but I like simple to hook up and use. A lot of it is just personal preference.

As far as robust enough, the Du-Bro bellcrank used on most of the linkage setups seems to work just fine. The Nylon bellcrank helps in trying to push the throttle too far open which can in turn bend the throttle shaft if your EPA's aren't set correctly.

As far as robust enough, the Du-Bro bellcrank used on most of the linkage setups seems to work just fine. The Nylon bellcrank helps in trying to push the throttle too far open which can in turn bend the throttle shaft if your EPA's aren't set correctly.

Please Log in or Create an account to join the conversation.

- Ronald Olson

- Offline

- Posts: 177

- Karma: 8

- Thank you received: 12

Steve Seebold replied the topic: Re: Zenoah throttle linkage solutions

I use the one from Insane Boats. Their part number is M14, I think the price is $12.95

Please Log in or Create an account to join the conversation.

- Steve Seebold

-

- Offline

- Posts: 636

- Karma: 4

- Thank you received: 39

marc replied the topic: Zenoah throttle linkage solutions

I've been using the standard bell crank setup from CC Racing, which is the same basic functionality as several others, and it's always served the purpose very well. The Speedmaster is different as that it not only pushes but also pulls, which some people believe is better for positive closure of the carb. In my opinion both systems work quite well when installed correctly on good working equipment.

www.modelgasboats.com

Sent from my iPhone using Tapatalk.

www.modelgasboats.com

Sent from my iPhone using Tapatalk.

"

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2491

- Karma: 24

- Thank you received: 55

Craig Dickson replied the topic: Re: Zenoah throttle linkage solutions

Hi Brian

It would be helpful to have full details of the issues you have had with your options so far. Why have they proved ineffective and “not responsive or robust enough” ?

For my contribution:

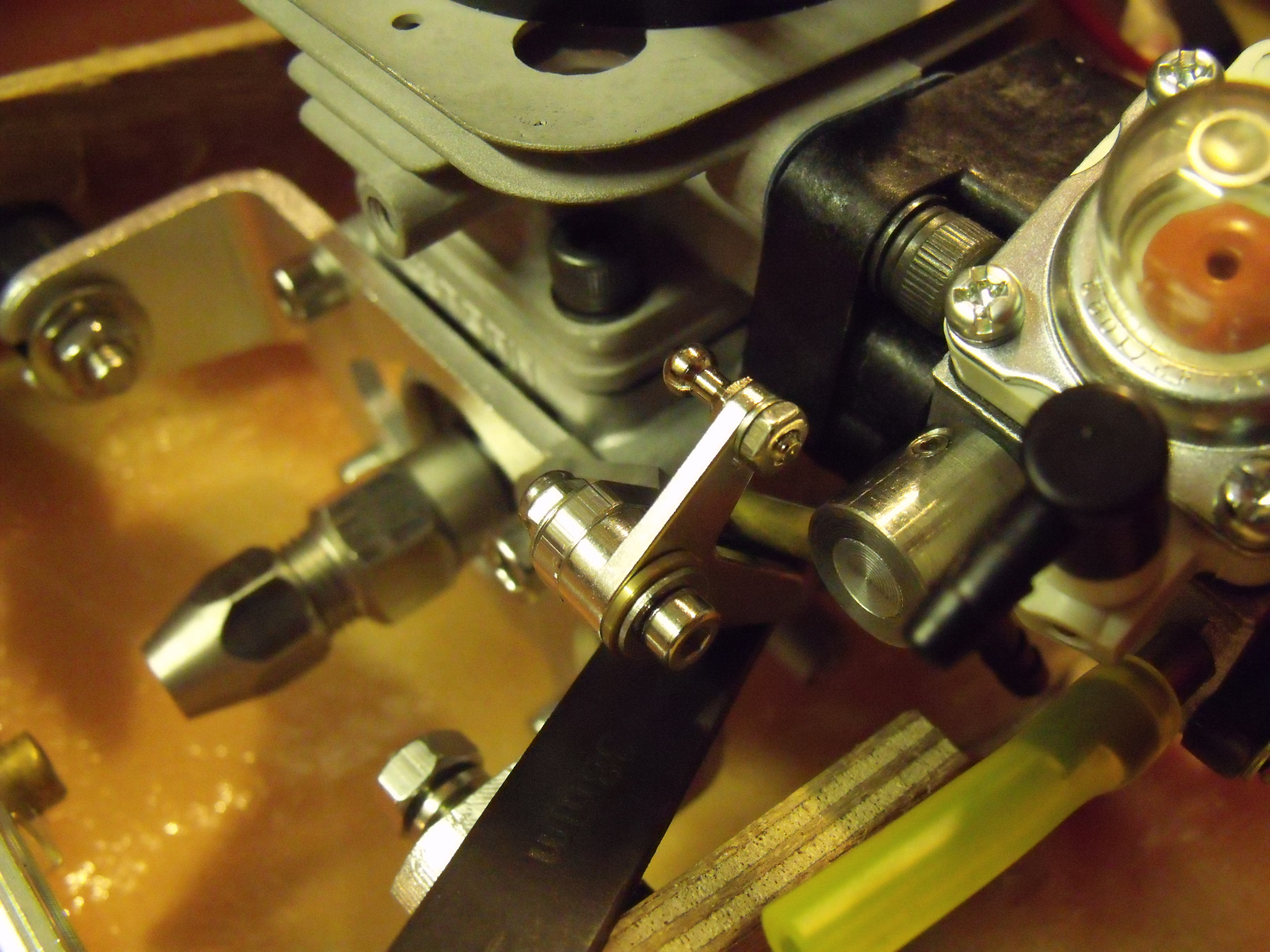

I have used two alternative push rod set ups on my mono boat. The initial set up is best explained with the photo below. A dubro ball link (on the bell crank) connected to the push rod to the servo (not shown). This set up failed when the butterfly valve got stuck open and the carb return spring failed to shut the engine down. With this set up the big danger is that the linkage pushes the throttle arm open but has no way of pulling it closed should the valve get stuck open. With this set up when the throttle is fully open the bell crank arm is exerting force (towards the transom) parallel to the butterfly mounting shaft which with my engine caused the butterfly to grind against the internal alloy barrel causing the “sticking”.

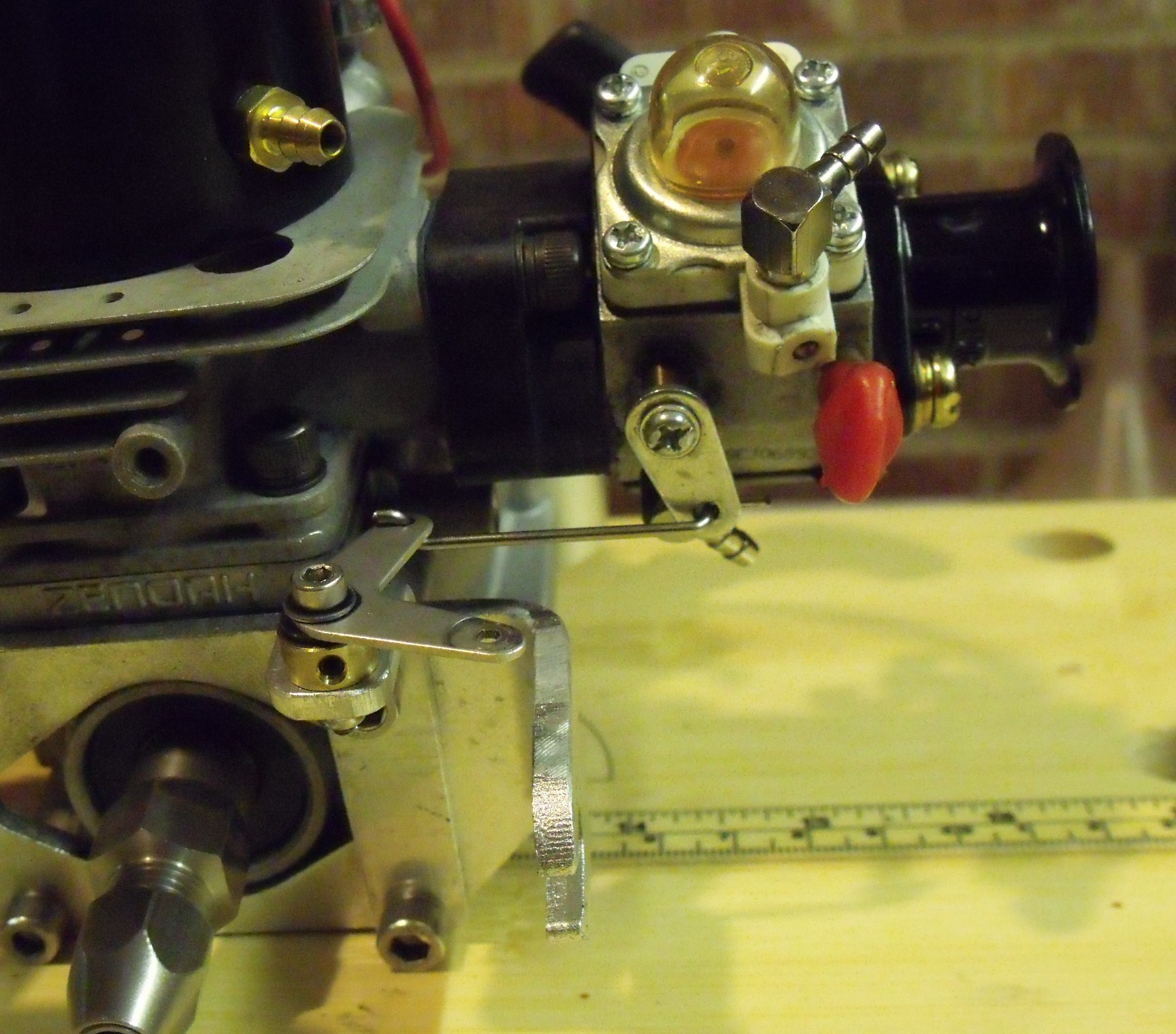

My solution to this issue is shown in the second photo. The servo push rod now connects to the steel bell crank arm and can now pull the throttle closed as well as pushing to open it. The return spring on the butterfly shaft keeps the set up tight for throttle sensitivity (with no natural play in the joints). The short steel pushrod between the bell crank and throttle arm is crude and would be better with ball joints. However it has worked faultlessly for the last two years.

My new boat will incorporate a neater version of this set up but with a Bowden cable instead of a push rod because the distance between the servo and engine is much bigger.

Cheers

Craig

Last edit: 13 years 1 month ago by Craig Dickson.

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Brcaward replied the topic: Re: Zenoah throttle linkage solutions

Fellow boaters, thank you for your responses. I apologise for not being more precise in my description of the problems I have had to date. My problems have been with systems which rely on the return spring to close the throttle (Craig has pictured and described these very well). I will go for the push-pull set up. Thanks again.

Please Log in or Create an account to join the conversation.

- Brcaward

- Offline

- Posts: 13

- Thank you received: 0

Time to create page: 0.120 seconds