Expanding PU buoyancy foam – do you use it??

Craig Dickson created the topic: Expanding PU buoyancy foam – do you use it??

Hi folks

This topic is meant to be a bit light hearted and hopefully provide a laugh at my expense.

Okay, when I built my second Gas Boat, I decided to fit a plywood bulkhead up front and fill the bow section with expanding polyurethane foam for buoyancy and strength.

This first photo shows the bulkhead in situ prior to the foam, all well and good so far with nice neatly cut expansion holes etc.

Being an inpatient man I figured the expanding foam didn’t seem to be doing much so I put plenty more in.

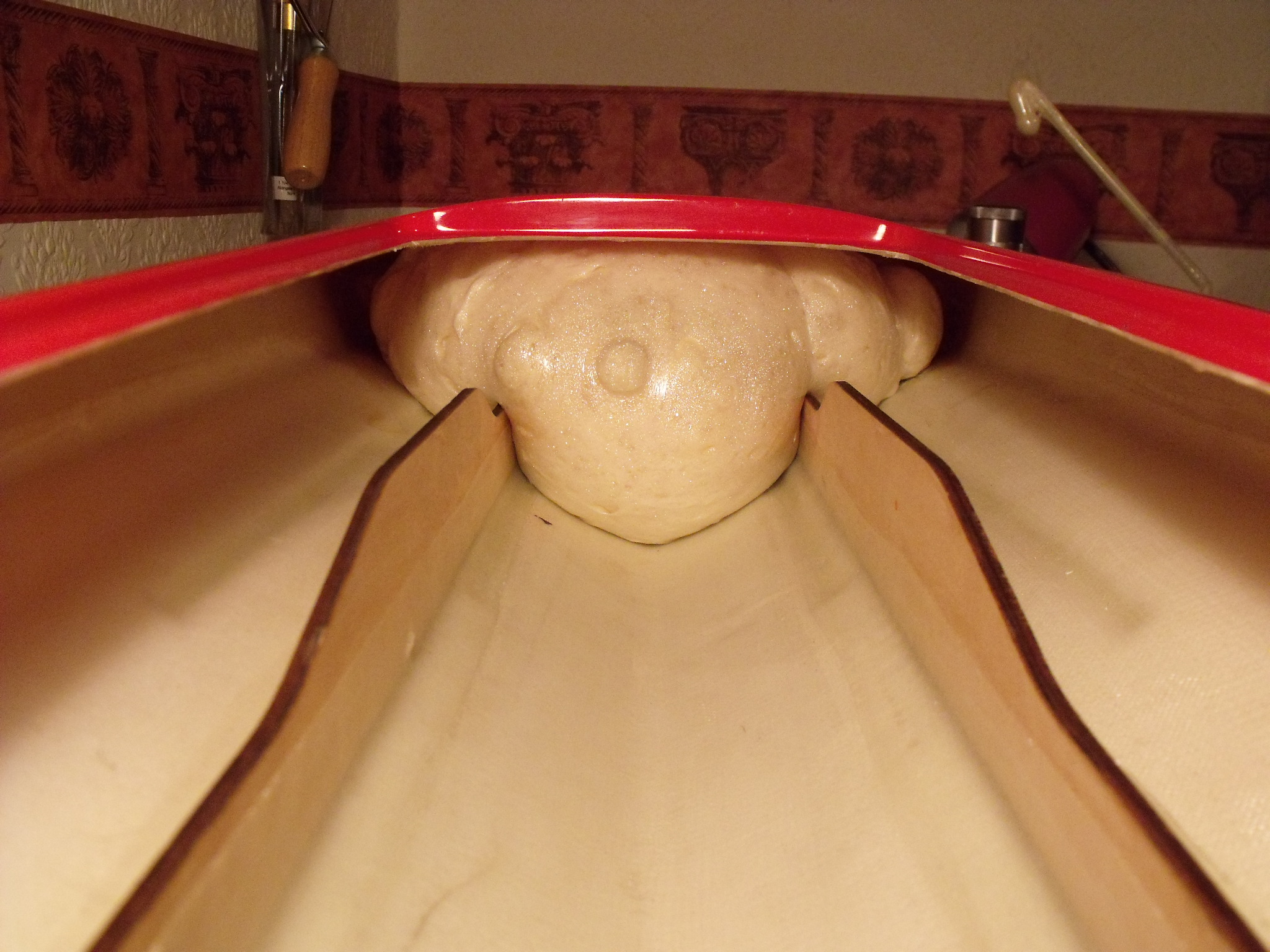

And then it seemed to start expanding more and more and I ended up with this (oh sh*t):

.............>

.............>

.............>

After it had fully set it took me a good while to cut the excess back to the bulkhead (before glassing it over) much to the delight of my wife whom laughed her wotsits off!

Anyway despite that hiccup, this clip shows that it did in the event save my boat from sinking when I had an accident. This clip also shows why I should have had more buoyancy in the mid/rear sections of the hull.

Cheers

Craig

This topic is meant to be a bit light hearted and hopefully provide a laugh at my expense.

Okay, when I built my second Gas Boat, I decided to fit a plywood bulkhead up front and fill the bow section with expanding polyurethane foam for buoyancy and strength.

This first photo shows the bulkhead in situ prior to the foam, all well and good so far with nice neatly cut expansion holes etc.

Being an inpatient man I figured the expanding foam didn’t seem to be doing much so I put plenty more in.

And then it seemed to start expanding more and more and I ended up with this (oh sh*t):

.............>

.............>

.............>

After it had fully set it took me a good while to cut the excess back to the bulkhead (before glassing it over) much to the delight of my wife whom laughed her wotsits off!

Anyway despite that hiccup, this clip shows that it did in the event save my boat from sinking when I had an accident. This clip also shows why I should have had more buoyancy in the mid/rear sections of the hull.

Cheers

Craig

Last edit: 13 years 5 months ago by Craig Dickson.

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

BrandonC replied the topic: Re: Expanding PU buoyancy foam – do you use it??

Well it worked pretty well in the end comic value aside!!  I was going to do the same but there are two vents on the front of mine which foam would have poured out of! Instead I shaped polystyrene blocks using a knife and stuffed them into the bow of the boat back to the fuel tank...whether it will save mine from sinking like your foam did is another question!!!

I was going to do the same but there are two vents on the front of mine which foam would have poured out of! Instead I shaped polystyrene blocks using a knife and stuffed them into the bow of the boat back to the fuel tank...whether it will save mine from sinking like your foam did is another question!!!

Please Log in or Create an account to join the conversation.

- BrandonC

- Offline

- Posts: 78

- Karma: 2

- Thank you received: 0

Craig Dickson replied the topic: Re: Expanding PU buoyancy foam – do you use it??

The reason why I like the expanding foam option is that it adds a great deal of strength to its enclosure. In this case the bow section of my hull.

Craig

Craig

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

BrandonC replied the topic: Re: Expanding PU buoyancy foam – do you use it??

That is a good point. Hows the electrics and engine after the partial sinking???

Please Log in or Create an account to join the conversation.

- BrandonC

- Offline

- Posts: 78

- Karma: 2

- Thank you received: 0

Craig Dickson replied the topic: Re: Expanding PU buoyancy foam – do you use it??

Hi Brandon

Just on your hull, you could have put a pre-fab insert underneath the air intakes (I like the position of those on your boat) and run the ventilation chamber to the bulkhead though I guess the access would make it tricky to get right.

After my partial sinking, the radio box was thankfully dry inside. Although a standard plastic box, it was much modified to reduce the risk of water ingress.

That included the square section brackets bolted + epoxied (with plastic epoxy) on the outside. Such that the box can be removed quickly by removing the four external bolts set into alloy studs glassed just outside the plywood rails.

The only four places that water can enter this box are the hatch, the two bellows and the switch push rod.

As to the engine luckily the air lock in the pipe appeared to have kept water getting inside the engine. First thing I did after retrieval was empty the fuel tank and put fresh fuel in. Then engine then fired up after three or four pulls and the boat was back in action with a good blast to dry out the engine and its bearings.

Cheers

Craig

Just on your hull, you could have put a pre-fab insert underneath the air intakes (I like the position of those on your boat) and run the ventilation chamber to the bulkhead though I guess the access would make it tricky to get right.

After my partial sinking, the radio box was thankfully dry inside. Although a standard plastic box, it was much modified to reduce the risk of water ingress.

That included the square section brackets bolted + epoxied (with plastic epoxy) on the outside. Such that the box can be removed quickly by removing the four external bolts set into alloy studs glassed just outside the plywood rails.

The only four places that water can enter this box are the hatch, the two bellows and the switch push rod.

As to the engine luckily the air lock in the pipe appeared to have kept water getting inside the engine. First thing I did after retrieval was empty the fuel tank and put fresh fuel in. Then engine then fired up after three or four pulls and the boat was back in action with a good blast to dry out the engine and its bearings.

Cheers

Craig

Last edit: 13 years 5 months ago by Craig Dickson.

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

BrandonC replied the topic: Re: Expanding PU buoyancy foam – do you use it??

Craig,

Glad to hear the boat survived unscathed. Come to think of it I actually don't have a forward bulkhead in my boat and I'm not sure it would fit anyway because of the fuel tank and the downward slant from the hatch forward, it would make it a tricky affair to put one in.

I like the inside of your boat, the engine rails and fiberglass work look very clean and tidy.

All the Best.

Glad to hear the boat survived unscathed. Come to think of it I actually don't have a forward bulkhead in my boat and I'm not sure it would fit anyway because of the fuel tank and the downward slant from the hatch forward, it would make it a tricky affair to put one in.

I like the inside of your boat, the engine rails and fiberglass work look very clean and tidy.

All the Best.

Please Log in or Create an account to join the conversation.

- BrandonC

- Offline

- Posts: 78

- Karma: 2

- Thank you received: 0

Craig Dickson replied the topic: Re: Expanding PU buoyancy foam – do you use it??

Hi Brandon

When fitting out my Lynx boat as per previous images, I had the same issue regarding the fuel tank pointing forward well into the bow of the hull. However I was determined to fit that front bulkhead for lateral strength and foam buoyancy beyond it.

I removed the preinstalled rails as I didn’t see them sufficiently thick and strong enough for the Zenoah engine.

My solution was a Dubaro tank mounted horizontally in a plywood cradle. Two plastic cable ties hold it in place permanently.

Cheers

Craig

When fitting out my Lynx boat as per previous images, I had the same issue regarding the fuel tank pointing forward well into the bow of the hull. However I was determined to fit that front bulkhead for lateral strength and foam buoyancy beyond it.

I removed the preinstalled rails as I didn’t see them sufficiently thick and strong enough for the Zenoah engine.

My solution was a Dubaro tank mounted horizontally in a plywood cradle. Two plastic cable ties hold it in place permanently.

Cheers

Craig

Last edit: 13 years 5 months ago by Craig Dickson.

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

David McIntyre replied the topic: Re: Expanding PU buoyancy foam – do you use it??

Guys, most people use pool noodles for flotation. Just stuff or tie it into wherever you want it to go. Can be glued into place if need be.

The expandable foam can on occasion keep expanding after you think it's set. You only know about ot when your hull splits apart. It is also known to absorb water after exposure. Pool noodles don't absorb water as they are 'closed cell'.

The foam used in full size boats is different to 'Gorilla' or other canned foam products, and it does indeed strengthen those hulls when applied correctly.

When full size powerboat hulls suffer cracks etc, water does still get in around that foam, and can be a pain to remove.

I once used expanding foam in a hollow core door to assist a repair - blew the door apart.

David

The expandable foam can on occasion keep expanding after you think it's set. You only know about ot when your hull splits apart. It is also known to absorb water after exposure. Pool noodles don't absorb water as they are 'closed cell'.

The foam used in full size boats is different to 'Gorilla' or other canned foam products, and it does indeed strengthen those hulls when applied correctly.

When full size powerboat hulls suffer cracks etc, water does still get in around that foam, and can be a pain to remove.

I once used expanding foam in a hollow core door to assist a repair - blew the door apart.

David

Please Log in or Create an account to join the conversation.

- David McIntyre

-

- Offline

- Posts: 106

- Thank you received: 0

marc replied the topic: Re: Expanding PU buoyancy foam – do you use it??

Personally, I stay away from the 2-part foam. I've had hands on experience with this destroying a wooden tunnel hull in the past. Water eventually made its way into the foam and just rotted everything. Plus the boat took on extra weight. Easy enough to get water to seep inside even the tightest spots, but almost impossible to get it back out though. As much as we like to think we've got things sealed, it's almost never 100%.

As for the foam sucking up water, I've also had pool noodles suck up considerable amounts of water. The difference though was that with the noodles I just took them out, threw them in the dumpster and put new ones in. Cleaned the inside of the hull while I was at it. You can see the discoloration of the fiberglass in a hull if the noodles actually hold moisture in there for too long...imagine what it can do in the long term if you can't get that moisture out.

I've also had the bad experience with the 2-part foam on my full size boat. It's a 2 layer FG construction, with the foam between the 2 layers of the hull. Exceptionally rigid, but guess what happened when a small crack developed in the keel and went unnoticed for a while? You got it, the darn foam sucked up all the water, hull weighed a ton and I had to open up the floor of the hull and tear out the foam. NOT a pleasant task let me tell you!

Anyway, I know for a fact that a lot of guys still like to use the 2-part foam, and I respect that, even some boat manufacturers will sell it with their boats, but me, I've had enough bad experiences with it to stay miles away!!!

As for the foam sucking up water, I've also had pool noodles suck up considerable amounts of water. The difference though was that with the noodles I just took them out, threw them in the dumpster and put new ones in. Cleaned the inside of the hull while I was at it. You can see the discoloration of the fiberglass in a hull if the noodles actually hold moisture in there for too long...imagine what it can do in the long term if you can't get that moisture out.

I've also had the bad experience with the 2-part foam on my full size boat. It's a 2 layer FG construction, with the foam between the 2 layers of the hull. Exceptionally rigid, but guess what happened when a small crack developed in the keel and went unnoticed for a while? You got it, the darn foam sucked up all the water, hull weighed a ton and I had to open up the floor of the hull and tear out the foam. NOT a pleasant task let me tell you!

Anyway, I know for a fact that a lot of guys still like to use the 2-part foam, and I respect that, even some boat manufacturers will sell it with their boats, but me, I've had enough bad experiences with it to stay miles away!!!

"

Last edit: 13 years 5 months ago by marc.

Please Log in or Create an account to join the conversation.

- marc

-

- Offline

- Posts: 2490

- Karma: 24

- Thank you received: 55

Craig Dickson replied the topic: Re: Expanding PU buoyancy foam – do you use it??

It is good to get a different angle from David and Marc. It demonstrates again that much is down to personal experience and that there is no such thing as a right or wrong way.

I am amazed that water penetration has caused so many issues because in my 30 years of using it in wood and composite model power boats, that has never been an issue. However I do ensure that entry and expansion holes are always glassed over with mat and resin to make the surface water proof after it is fully cured.

David made a valid point about the foam potentially expanding when you think it has set. I have found that to happen if using the single mix can types where you just squirt the stuff into the void to be filled.

As an experiment I recently filled a big cardboard box with half a can of this stuff. After the exterior of the foam block was well set and seemingly stable I removed the foam block and left it for a couple of weeks. Then I sliced it in half and discovered that interior section was still liquid and it immediately started to cure and expand in the process. That taught me that it is best to use this stuff in smaller quantities to layer up the foam in stages. This type of product relies upon moisture to catalyse the chemical reaction. Once the outside of a big application of foam has set and cured, the interior remains like the sealed contents of the can, that is liquid form waiting to eventually cure thus the risk of unexpected expansion at a later date.

The other thing I learnt with the can type of PU foam (that I used) is that it seems very sensitive to temperature (as well as humidity) in respect of how quickly it expands and cures. A warm environment with a fine spray of water applied inside the void makes it expand more quickly and from my experience seems to make it cure better with consistency in the process.

My favourite type of foam is the two part liquid mix, by a mile. It has a decent shelf life unlike the single spray can type and is much more easy to apply providing that you work quickly during the mixing process. With the two part foam, if you haven’t filled the void you simply mix up a bit more with no messy cleaning of a nozzle of the alternative can type.

Also with the two part I find that it is easier (with experience) to estimate the necessary quantity of liquid mix needed to fill the required section.

My original images in this topic showed the use of a spray can application. Next time I will revert back to the two part mix providing that I can find a supplier of the required density for a model boat application.

Regards

Craig

I am amazed that water penetration has caused so many issues because in my 30 years of using it in wood and composite model power boats, that has never been an issue. However I do ensure that entry and expansion holes are always glassed over with mat and resin to make the surface water proof after it is fully cured.

David made a valid point about the foam potentially expanding when you think it has set. I have found that to happen if using the single mix can types where you just squirt the stuff into the void to be filled.

As an experiment I recently filled a big cardboard box with half a can of this stuff. After the exterior of the foam block was well set and seemingly stable I removed the foam block and left it for a couple of weeks. Then I sliced it in half and discovered that interior section was still liquid and it immediately started to cure and expand in the process. That taught me that it is best to use this stuff in smaller quantities to layer up the foam in stages. This type of product relies upon moisture to catalyse the chemical reaction. Once the outside of a big application of foam has set and cured, the interior remains like the sealed contents of the can, that is liquid form waiting to eventually cure thus the risk of unexpected expansion at a later date.

The other thing I learnt with the can type of PU foam (that I used) is that it seems very sensitive to temperature (as well as humidity) in respect of how quickly it expands and cures. A warm environment with a fine spray of water applied inside the void makes it expand more quickly and from my experience seems to make it cure better with consistency in the process.

My favourite type of foam is the two part liquid mix, by a mile. It has a decent shelf life unlike the single spray can type and is much more easy to apply providing that you work quickly during the mixing process. With the two part foam, if you haven’t filled the void you simply mix up a bit more with no messy cleaning of a nozzle of the alternative can type.

Also with the two part I find that it is easier (with experience) to estimate the necessary quantity of liquid mix needed to fill the required section.

My original images in this topic showed the use of a spray can application. Next time I will revert back to the two part mix providing that I can find a supplier of the required density for a model boat application.

Regards

Craig

Please Log in or Create an account to join the conversation.

- Craig Dickson

- Offline

- Posts: 192

- Thank you received: 4

Time to create page: 0.248 seconds